Operation Theatre Doors

When it comes to hospitals and healthcare facilities, every detail is designed with one purpose in mind—patient safety. Among the most critical yet often overlooked elements of healthcare infrastructure is the operation theatre door. Unlike standard doors, these specialized systems are engineered to maintain sterility, support hygiene protocols, and create a safe working environment for doctors, nurses, and patients.

A properly designed hospital theatre door acts as a barrier against airborne contaminants, dust, and external pollutants. It ensures that the operation theatre remains a controlled environment where surgical procedures can be performed without the risk of infection. In fact, many hospitals across the world consider OT doors to be the first line of defense in infection control, as they help regulate airflow, pressure differentials, and even noise levels in surgical areas.

Modern healthcare facilities demand more than just basic functionality. Today’s hospital operation theatre door solutions must combine strength with precision, hygiene with efficiency, and durability with innovation. From supporting smooth movement of patients and equipment to ensuring ease of cleaning and sterilization, the design of these doors directly impacts the overall efficiency of surgical departments.

At Technopuff Solutions, we understand these challenges deeply. That’s why we design and manufacture specialized operation theatre doors using high-quality PUF panels. Our PUF-based OT doors offer superior thermal insulation, lightweight strength, and long-lasting durability—all while being easy to clean and resistant to microbial growth. These features make them ideal for critical healthcare environments where safety and hygiene cannot be compromised.

Why Operation Theatre Doors Are Crucial in Healthcare

In modern hospitals, maintaining a sterile and controlled environment is not just important—it is life-saving. One of the key components that make this possible is the operation theatre door. Unlike conventional entrances, hospital theatre doors are designed to perform multiple critical functions that directly influence patient safety, surgical outcomes, and the efficiency of hospital operations.

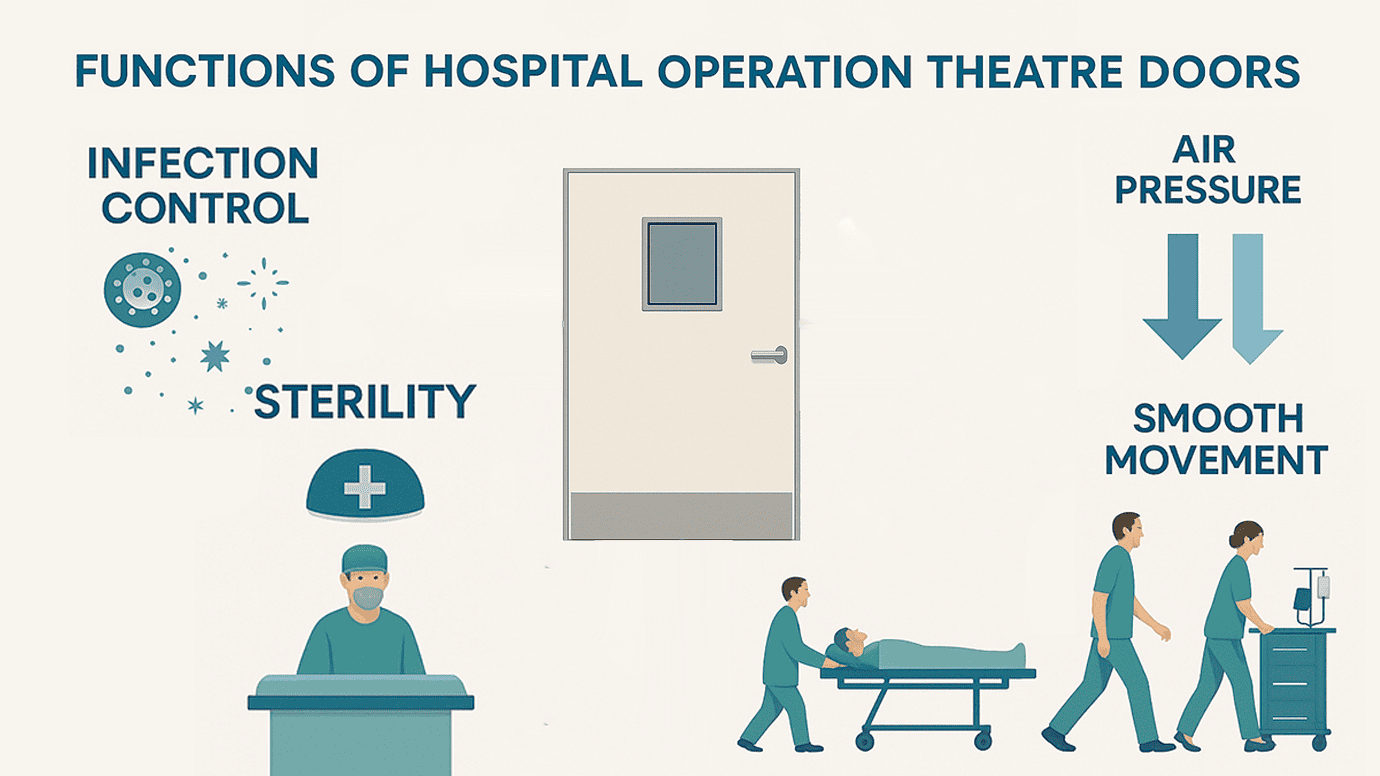

Role of OT Doors in Infection Control

The number one priority inside an operation theatre is infection prevention. Specialized OT doors act as a shield against dust particles, bacteria, and airborne contaminants that could otherwise enter the sterile zone. By offering airtight sealing and smooth, hygienic surfaces, the hospital operation theatre door minimizes the risk of cross-contamination. This is especially vital in high-risk surgeries where even minor infections can pose serious threats to patient recovery.

Controlling Air Pressure and Maintaining Sterile Environment

One of the most overlooked but critical functions of an operation theatre door is its ability to support pressure control. Surgical areas often maintain positive or negative air pressure depending on the procedure. High-quality hospital theatre doors help to ensure that this controlled airflow is not disrupted, thereby preserving the sterile environment inside. This control also prevents pathogens from leaking into surrounding hospital spaces, making OT doors an essential part of hospital infection control systems.

Ensuring Smooth Movement of Staff, Stretchers, and Equipment

Apart from sterility and infection control, functionality is another important factor. In high-stress medical environments, staff and equipment must move quickly and efficiently. A well-designed hospital operation theatre door ensures smooth, unobstructed passage for doctors, nurses, stretchers, and surgical equipment. Whether it is a single-leaf or double-leaf structure, OT doors are built to accommodate heavy usage while ensuring safety and durability.

In summary, operation theatre doors are not just physical barriers—they are an integral part of hospital safety protocols. From infection control to workflow efficiency, hospital theatre doors play a vital role in keeping healthcare facilities compliant with international standards while safeguarding both patients and medical professionals.

Features of PUF Panel Operation Theatre Doors

When selecting an operation theatre door, hospitals must look beyond just functionality. The right door must guarantee hygiene, durability, and performance while complying with strict medical standards. This is why PUF panel technology has become the preferred choice for hospital theatre doors. At Technopuff Solutions, we design OT doors using high-quality PUF panels that combine engineering precision with healthcare safety. Here are the standout features:

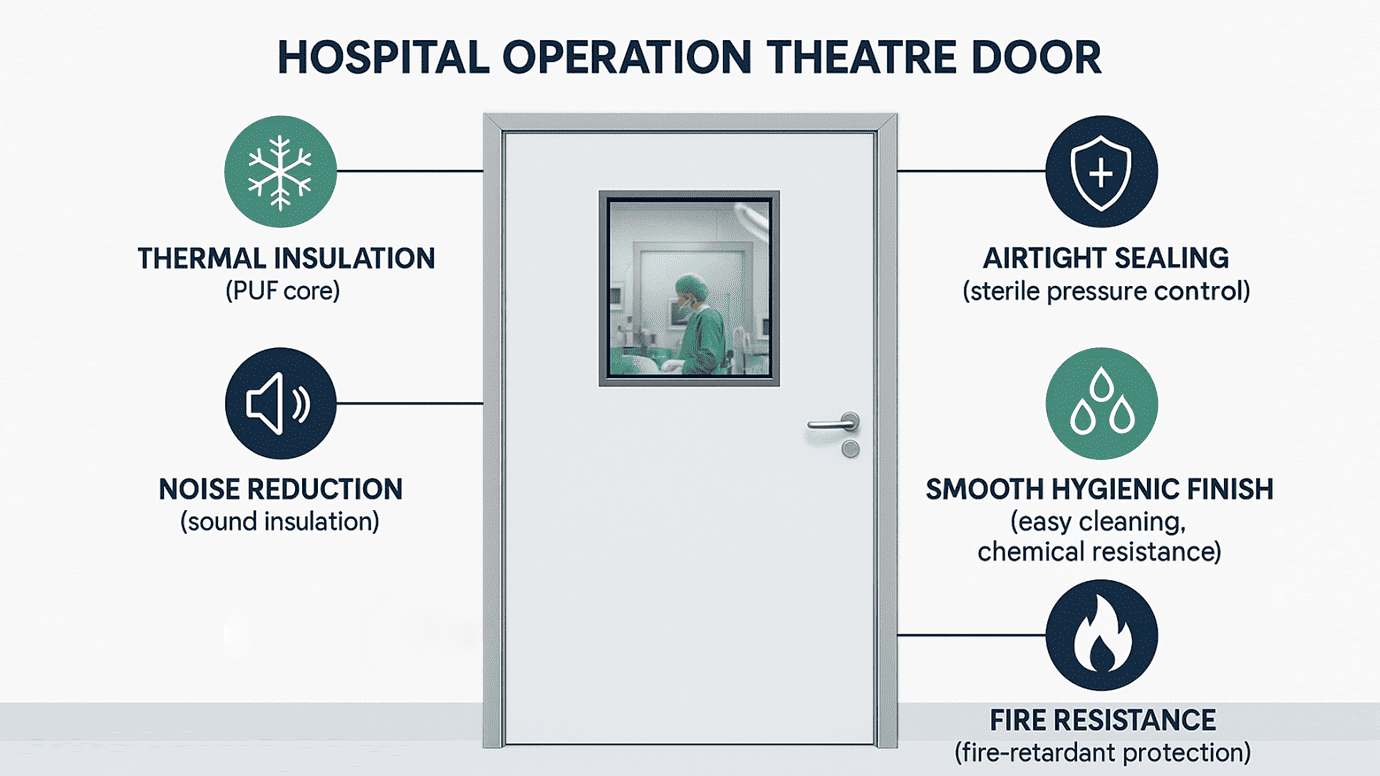

PUF Panel Core – Insulation, Durability, and Lightweight Strength

At the heart of every hospital operation theatre door lies a PUF (Polyurethane Foam) core. This core provides excellent thermal insulation, helping to maintain consistent temperatures in sensitive surgical environments. The lightweight yet durable structure ensures long service life and ease of use. Such an operation theatre door design reduces energy consumption while offering unmatched strength and stability.

Air-tight Sealing – Ensuring Sterility and Pressure Control

One of the most critical requirements of an operation theatre door is its ability to prevent contamination. Our PUF panel-based hospital theatre doors come with advanced air-tight sealing systems that ensure no air leakage. This helps in maintaining sterile pressure zones inside the operation theatre, ensuring proper airflow and minimizing the risk of infection. With this feature, OT doors become a vital part of hospital infection control strategies.

Smooth, Hygienic Finish – Easy to Clean and Resistant to Chemicals

Hygiene is non-negotiable in hospitals. That’s why every hospital operation theatre door we manufacture comes with a smooth, non-porous finish. This surface is easy to clean, resistant to chemicals, and does not allow bacterial growth. Such an operation theatre door design ensures quick sterilization, making it ideal for environments where sanitation is a top priority.

Fire Resistance – Safety in Critical Healthcare Zones

In a hospital, safety cannot be compromised. Our OT doors are engineered with fire-resistant properties, offering added protection in case of emergencies. By using PUF panels with special fire-retardant features, we ensure that the hospital theatre doors not only maintain sterility but also safeguard lives during unforeseen incidents.

Noise Reduction – Enhancing Patient and Staff Comfort

Hospitals are high-stress environments where peace and concentration are vital. PUF panel operation theatre doors provide excellent sound insulation, reducing noise from surrounding areas. This helps doctors and staff maintain focus during surgeries and also creates a calmer environment for patients. With such thoughtful operation theatre door design, comfort and functionality go hand in hand.

PUF panel operation theatre doors bring together hygiene, safety, and durability in one solution. From insulation to infection control, every feature of these specialized hospital theatre doors is tailored to meet the unique challenges of healthcare environments.

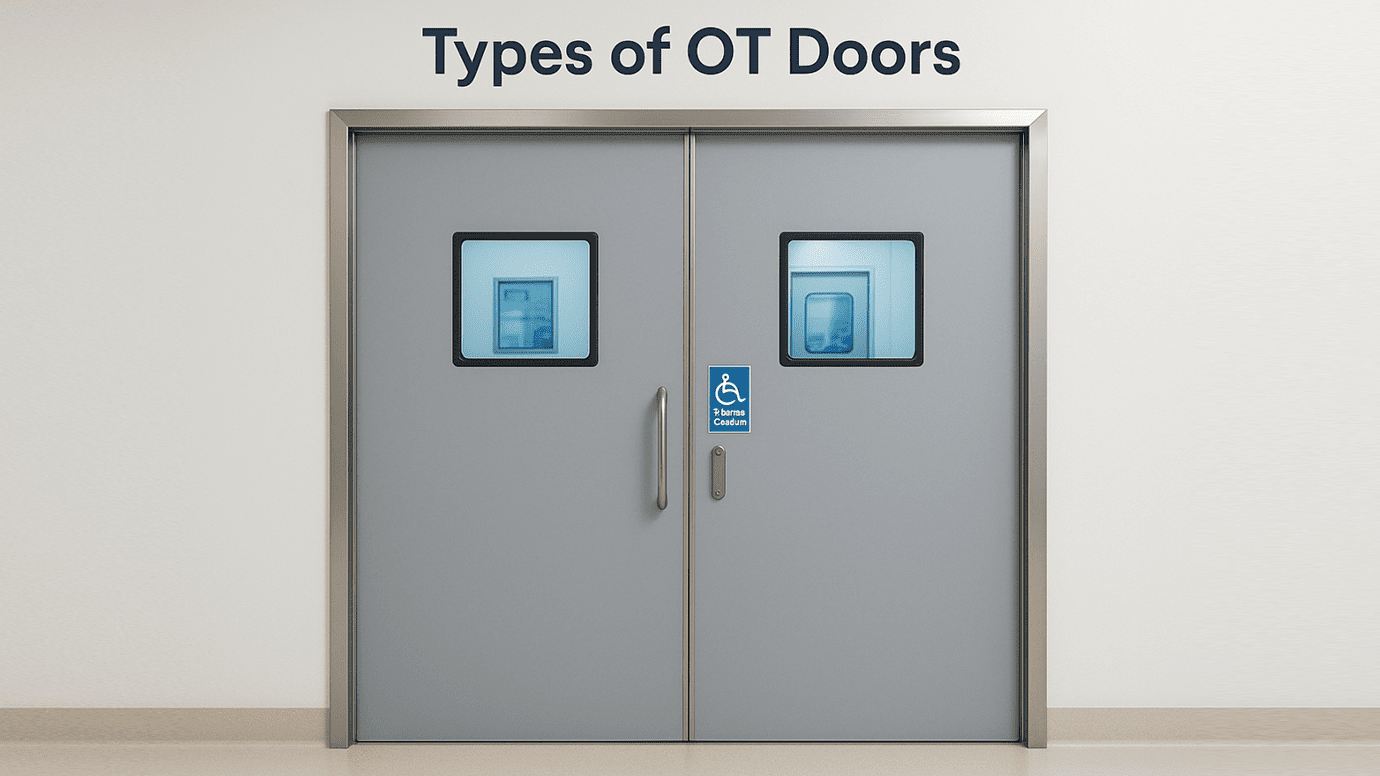

Types of Operation Theatre Doors

Every healthcare facility has unique requirements, and the right operation theatre door must be chosen based on functionality, space, and hygiene standards. At Technopuff Solutions, we offer a wide range of hospital theatre doors built with precision-engineered PUF panels to suit different hospital needs. From traditional swing doors to high-tech hermetically sealed systems, our OT doors are designed to provide durability, sterility, and smooth functionality. Below are the most popular options available.

Swing OT Doors – Single and Double Leaf

The most widely used hospital operation theatre door type is the swing OT door. Available in single-leaf or double-leaf configurations, these doors are practical, durable, and easy to operate. They allow smooth entry and exit for staff, patients, and equipment, making them ideal for busy surgical environments. With our advanced operation theatre door design, swing OT doors are built with PUF panels for superior insulation, hygiene, and long-lasting performance.

Sliding OT Doors – Space-Saving and Efficient

In hospitals where space optimization is critical, sliding OT doors are an excellent choice. These operation theatre doors glide smoothly along tracks, saving valuable floor space while maintaining airtight sealing. Our hospital theatre doors with sliding mechanisms are particularly effective in compact surgical areas where every inch matters. This type of operation theatre door design combines efficiency with sterility, making it both practical and safe for modern hospitals.

Automatic OT Doors – Sensor-Based, Touchless Entry

Automation is becoming a standard in advanced healthcare facilities, and automatic OT doors provide the perfect solution. These doors come with sensor-based systems that enable touchless operation, reducing the risk of cross-contamination. Automatic hospital theatre doors are especially useful in high-traffic areas, as they ensure seamless movement of staff, stretchers, and equipment without physical contact. Our operation theatre door design ensures that automation integrates smoothly with hygiene and safety standards.

Hermetically Sealed OT Doors – Ultra-Sterile Protection

For critical areas where maintaining absolute sterility is non-negotiable, hermetically sealed OT doors are the ideal choice. These specialized hospital operation theatre doors are designed to create an airtight barrier, preventing any leakage of air or contaminants. With precision-engineered operation theatre door design, hermetically sealed doors help maintain pressure-controlled environments, making them suitable for advanced surgical theatres, cleanrooms, and pharmaceutical labs.

In short, whether you choose swing, sliding, automatic, or hermetically sealed OT doors, Technopuff Solutions delivers customized solutions that balance functionality, hygiene, and safety. Each operation theatre door we manufacture is designed to meet hospital standards while offering durability, ease of use, and superior infection control.

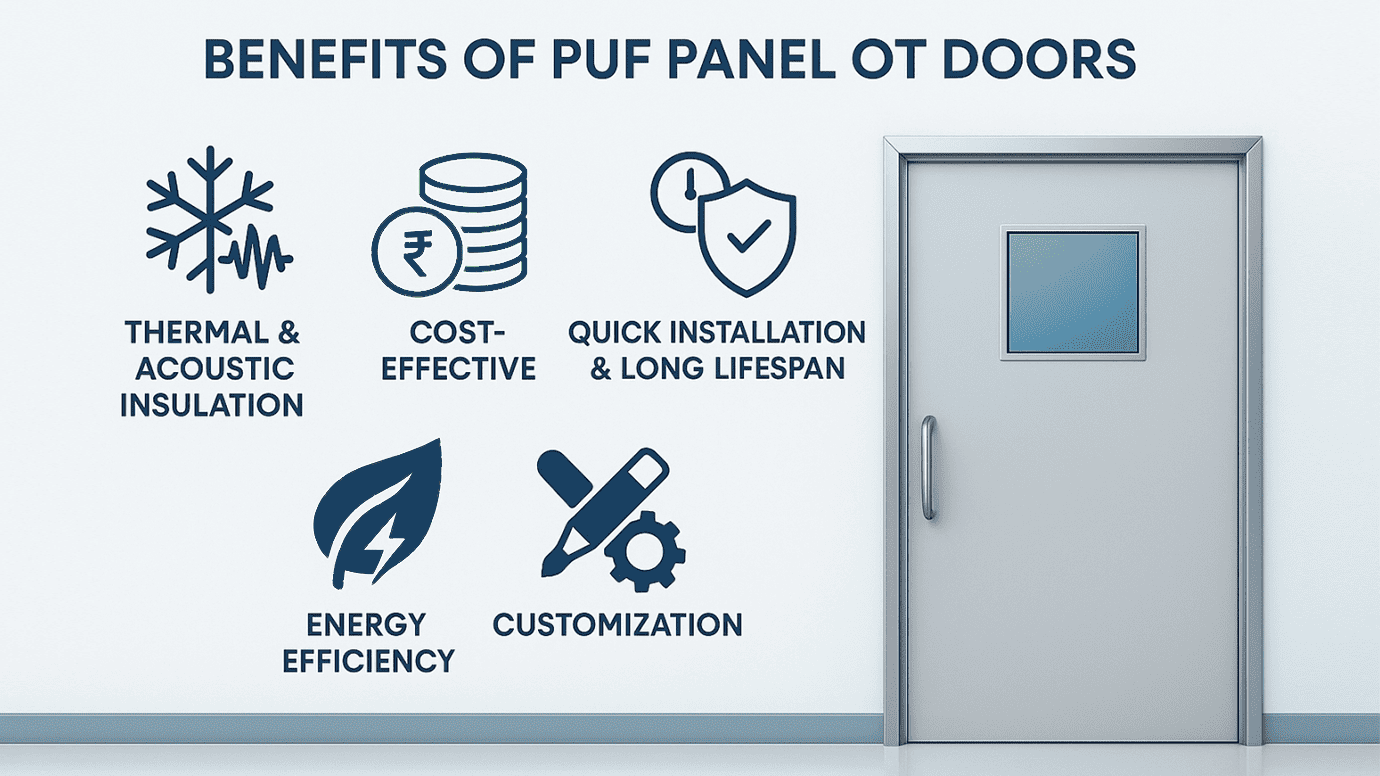

Benefits of Using PUF Panel OT Doors

Choosing the right operation theatre door is not just about access; it is about ensuring long-term performance, hygiene, and efficiency in critical hospital environments. At Technopuff Solutions, our hospital theatre doors made from high-quality PUF panels are designed to deliver multiple advantages over traditional wooden or metal doors. From insulation to customization, these OT doors offer hospitals a smart investment that balances safety with cost-effectiveness.

Superior Thermal and Acoustic Insulation

A PUF panel-based hospital operation theatre door provides excellent thermal insulation, helping maintain stable temperatures inside operation theatres. This ensures that air-conditioning systems work efficiently while surgical environments remain sterile and comfortable. Additionally, the same PUF core delivers acoustic insulation, reducing noise transfer between wards and surgical areas. With this feature, our operation theatre door design improves both medical precision and patient comfort.

Cost-Effective Compared to Traditional Doors

Installing high-quality OT doors does not have to be expensive. Unlike conventional materials, PUF panel-based hospital theatre doors are cost-effective while offering far better performance in terms of insulation, durability, and hygiene. Hospitals save significantly on long-term maintenance, as each operation theatre door is resistant to wear, moisture, and chemical exposure.

Quick Installation and Long Lifespan

Time is crucial in hospital projects, and our hospital operation theatre doors are designed for quick installation without compromising quality. The lightweight nature of PUF panels makes the process faster and more efficient, reducing downtime in hospital operations. Once installed, these OT doors offer a long lifespan, performing reliably even under continuous, heavy usage.

Supports Energy Efficiency in Hospitals

Energy costs are a significant part of hospital expenses. By using operation theatre doors with PUF panel insulation, hospitals can minimize energy losses and reduce the load on HVAC systems. This makes our hospital theatre doors an eco-friendly choice that supports green building standards. With energy efficiency built into every operation theatre door design, hospitals not only save costs but also contribute to sustainability.

Customizable to Size, Color and Specifications

Every hospital has unique requirements, and that is why we offer complete customization for our hospital operation theatre doors. Whether it’s size, color, or specific technical features, we design OT doors that perfectly match the hospital’s infrastructure and aesthetic needs. This level of flexibility ensures that every operation theatre door not only performs efficiently but also blends seamlessly into the healthcare environment.

PUF panel operation theatre doors offer unmatched benefits—ranging from insulation and durability to cost-effectiveness and customization. With their advanced design, Technopuff Solutions provides hospital theatre doors that meet the highest standards of hygiene, safety, and long-term value. If you want to know about doors for Cold room, you can read our detailed blog on Cold Room Doors.

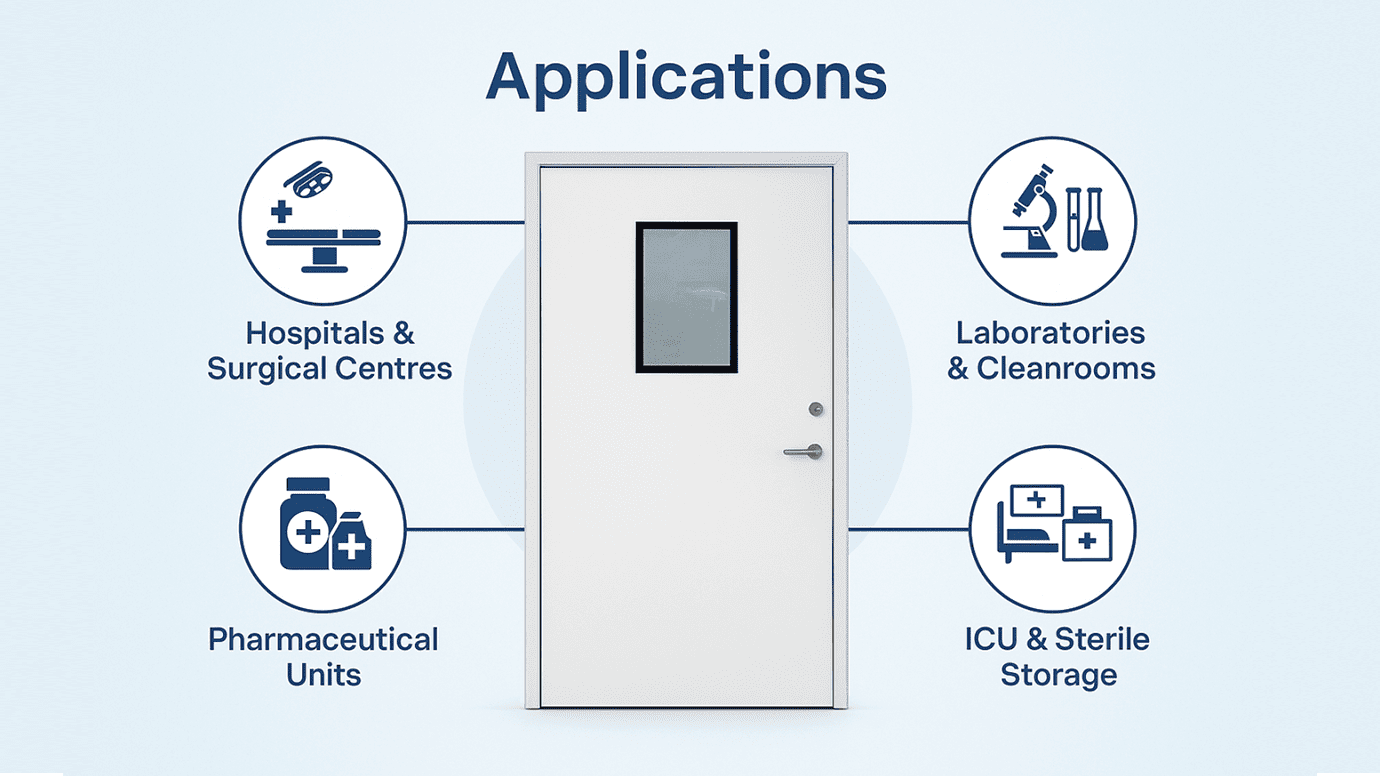

Applications of Operation Theatre Doors

A well-designed operation theatre door is not limited to just surgical spaces—it plays a vital role in multiple environments where sterility, hygiene, and safety are critical. At Technopuff Solutions, we manufacture PUF panel-based hospital theatre doors that can be adapted to diverse industries and facilities. From hospitals to pharmaceutical units, our OT doors are engineered to meet stringent standards of performance and cleanliness.

Hospitals & Surgical Centres

The primary application of any hospital operation theatre door is, of course, in surgical theatres and procedure rooms. These areas demand airtight sealing, smooth operation, and hygienic finishes to protect patients and staff during critical medical procedures. By installing high-quality OT doors, hospitals can minimize infection risks, control airflow, and improve overall efficiency in operating theatres and surgical departments.

Laboratories and Cleanrooms

Outside hospitals, laboratories also require environments that are free from contamination. Our operation theatre door design is ideally suited for laboratories and cleanrooms, where precision and sterility are paramount. With PUF panel insulation and airtight sealing, these hospital theatre doors ensure that dust, microbes, and external pollutants are kept out, protecting sensitive experiments, testing procedures, and delicate equipment.

Pharmaceutical Manufacturing Units

In pharmaceutical industries, maintaining strict hygiene standards is essential to ensure product quality and compliance with regulations. Our operation theatre doors are widely used in manufacturing plants, packaging areas, and sterile production units. These OT doors prevent contamination, control temperature, and support smooth operations inside high-risk pharmaceutical environments. With their hygienic surfaces and long-lasting durability, PUF panel hospital operation theatre doors provide a reliable solution for pharma cleanrooms.

ICU and Sterile Storage Areas

Another important application of hospital theatre doors is in intensive care units (ICUs) and sterile storage zones. These sensitive areas must remain infection-free at all times to protect vulnerable patients and preserve sterilized medical equipment. Installing high-performance operation theatre doors ensures that these zones remain isolated, contamination-free, and compliant with hospital safety standards. The airtight design of our OT doors plays a key role in maintaining these controlled environments.

PUF panel operation theatre doors are versatile solutions used across hospitals, laboratories, pharmaceutical units, ICUs, and sterile storage areas. Whether it’s protecting patients during surgery or ensuring contamination-free production in pharma plants, Technopuff Solutions’ hospital theatre doors deliver unmatched reliability and performance.

Why Choose Technopuff Solutions for OT Doors

Selecting the right partner for your operation theatre door requirements is just as important as choosing the design itself. Hospitals and healthcare facilities cannot compromise on quality, hygiene, or durability when it comes to critical infrastructure. At Technopuff Solutions, we bring unmatched expertise and innovation to deliver world-class hospital theatre doors that exceed industry standards. Here’s why we are the trusted choice for OT doors across India.

In-House Manufacturing with Strict Quality Control

Unlike suppliers who outsource production, we handle the complete process of designing and manufacturing each hospital operation theatre door in-house. This ensures that every door is built under strict quality control, with no compromise on precision or safety. From raw materials to the final product, every stage undergoes rigorous inspection to meet hospital-grade standards.

Use of PUF Panel Technology for Durability and Hygiene

At the core of our innovation lies the use of advanced PUF panel technology. This gives our operation theatre doors superior insulation, lightweight strength, and resistance to moisture and chemicals. With this, our hospital theatre doors not only last longer but also maintain strict hygiene standards that are vital in surgical environments. The PUF-based operation theatre door design makes cleaning and maintenance easier, ensuring uninterrupted performance for years.

Custom Solutions Tailored to Hospital Needs

We understand that every hospital has unique requirements, which is why we specialize in creating customized hospital operation theatre doors. Whether you need single-leaf, double-leaf, sliding, or hermetically sealed OT doors, we design solutions that perfectly match your hospital’s infrastructure, workflow, and aesthetics. Our ability to adapt operation theatre door design to client specifications ensures complete satisfaction and long-term value.

Trusted by Leading Clients Across Industries

Over the years, Technopuff Solutions has built strong relationships with reputed clients across healthcare, pharmaceuticals, and research facilities. Our hospital theatre doors are trusted by organizations that demand nothing less than perfection. This trust is built on our consistent commitment to delivering durable, hygienic, and reliable operation theatre doors that perform exceptionally well in high-pressure environments.

Technopuff Solutions is not just a manufacturer but a partner in building safer healthcare spaces. By combining in-house expertise, cutting-edge PUF technology, and tailor-made operation theatre door designs, we deliver OT doors that hospitals can depend on for safety, hygiene, and efficiency.

FAQs

A. An operation theatre door is a specialized barrier designed to maintain sterility, hygiene, and safety in surgical environments. Unlike standard doors, these doors prevent contamination, regulate airflow, and ensure infection control during medical procedures.

A. PUF panel hospital theatre doors provide superior insulation, durability, and hygiene compared to traditional wooden or metal doors. Their lightweight yet strong structure makes them ideal for critical hospital applications where cleanliness and performance are essential.

A.PUF panel doors are insulated doors made with a polyurethane foam (PUF) core, offering excellent thermal insulation, durability, and hygiene. They are widely used in hospitals, cleanrooms, cold storage, and industrial applications for maintaining controlled environments. For more information, you can read our detailed blog on PUF Panel Doors.

A. Hospitals can choose from various OT doors such as swing doors (single or double leaf), sliding doors, automatic sensor-based doors, and hermetically sealed doors. Each operation theatre door design is tailored to meet the functional and space requirements of different healthcare facilities.

A. Airtight sealing in an operation theatre door prevents air leakage and contamination. It helps maintain pressure-controlled environments, ensuring sterile conditions inside surgical theatres and supporting hospital infection control protocols.

A. Yes, PUF panel-based hospital operation theatre doors provide excellent thermal insulation. By maintaining consistent indoor temperatures, they reduce the load on HVAC systems, resulting in lower energy consumption and greater efficiency for hospitals.

A. High-quality PUF panel OT doors are manufactured with fire-retardant materials that offer added safety in critical healthcare zones. This feature ensures that hospital theatre doors can slow down fire spread and protect patients and staff during emergencies.

Conclusion

The choice of an operation theatre door is not just a technical decision—it is a vital investment in patient safety, hospital efficiency, and long-term reliability. With the advanced use of PUF panel technology, Technopuff Solutions has redefined the standards of modern hospital theatre doors by combining insulation, hygiene, durability, and ease of maintenance in one complete solution.

From infection control to noise reduction, from airtight sealing to fire resistance, our OT doors are designed to meet the toughest demands of surgical environments. Each hospital operation theatre door we manufacture is engineered with precision to support sterility, improve energy efficiency, and deliver lasting value. Hospitals that choose Technopuff Solutions benefit from superior operation theatre door design, tailored solutions, and trusted quality that align with international healthcare standards.

At Technopuff Solutions, we don’t just manufacture hospital theatre doors—we build confidence for hospitals, doctors, and patients. Our PUF panel operation theatre doors are proof that safety, hygiene, and innovation can work hand in hand to create healthier healthcare spaces.

Contact us today to get high-quality operation theatre doors designed to meet your hospital’s specific needs. Let us help you enhance safety, improve efficiency, and ensure compliance with modern healthcare requirements through our advanced operation theatre door design solutions. For more information regarding PUF Panels and doors and related structures, go to our Homepage.