Cold Room Doors

In temperature-sensitive industries, cold room doors are more than just entryways—they are critical components that determine the efficiency, safety, and performance of an entire cold storage facility. Whether it’s a food processing plant, a pharmaceutical warehouse, a dairy unit, or a logistics hub, maintaining a consistent temperature is essential to preserve product quality, ensure regulatory compliance, and reduce wastage. This is where the importance of well-engineered cold storage doors becomes evident.

Unlike conventional doors, cold room doors are specifically designed to minimize thermal transfer and maintain airtight sealing. They prevent warm air infiltration and cold air leakage, ensuring that the refrigeration system works optimally. By maintaining stable internal conditions, these doors directly contribute to energy savings, longer product shelf life, and reduced operational costs. For businesses operating in highly competitive sectors like food exports or pharmaceutical distribution, the right door can be the difference between profit and loss.

When it comes to material choice, PUF (Polyurethane Foam) insulated cold room doors are recognized globally as the most efficient and durable option. The high-density PUF core offers excellent thermal insulation, superior mechanical strength, and long-lasting performance. Unlike traditional alternatives, these doors are lightweight yet robust, moisture-resistant, and capable of withstanding frequent usage without compromising insulation. Their eco-friendly design also ensures lower energy consumption, aligning with modern sustainability goals.

This is where Technopuff Solutions sets itself apart. As one of the most trusted cold room doors manufacturers and suppliers in India, the company specializes in delivering customized, high-performance door solutions crafted from advanced PUF panels. Backed by modern technology, strict quality control, and a customer-first approach, Technopuff ensures that every door is engineered for insulation, durability, and energy efficiency. From small-scale storage units to large industrial cold chains, Technopuff Solutions provides doors that enhance operational efficiency while protecting valuable goods under precise temperature conditions.

What are Cold Room Doors?

In simple terms, cold room doors are specialized entry systems designed for refrigerated and temperature-controlled spaces. Unlike ordinary doors, they are engineered to create a perfect thermal barrier, ensuring that the cold air inside a storage unit remains locked in while preventing external heat and moisture from entering. This makes them one of the most crucial components in industries that rely on cold storage facilities, such as food processing, pharmaceuticals, floriculture, and logistics.

The role of cold storage doors goes far beyond providing physical access. They directly influence the temperature integrity of the entire cold room. Even the most advanced refrigeration system and the most durable insulated panels can fail to deliver optimal performance if the doors are poorly designed or inadequately insulated. Every time the door opens and closes, there is potential for energy loss; hence, the construction and sealing of the door become vital in controlling both temperature and operating costs.

High-quality cold room doors ensure:

- Consistent temperature levels inside the cold room.

- Reduced energy consumption, as the refrigeration system does not need to overcompensate for thermal leakage.

- Extended product shelf life, especially for perishable goods.

- Operational efficiency, with smooth door handling and long-lasting performance.

Just like walls and roofing in a cold storage facility, the insulation quality of the door plays a critical role in achieving complete thermal efficiency. A poorly insulated door can cause significant thermal bridging, leading to ice formation, product spoilage, and inflated electricity bills. That’s why advanced doors made with PUF-insulated panels are widely recommended—they offer superior thermal resistance, lightweight strength, and durability.

For businesses seeking long-term reliability, choosing the right door is not optional—it’s a necessity. That’s why many industries prefer working with trusted cold room doors manufacturers and established suppliers who understand the science of insulation and the demands of heavy-duty operations. By selecting the right partner, businesses can ensure they invest in cold room doors that deliver maximum efficiency, safety, and cost savings over time.

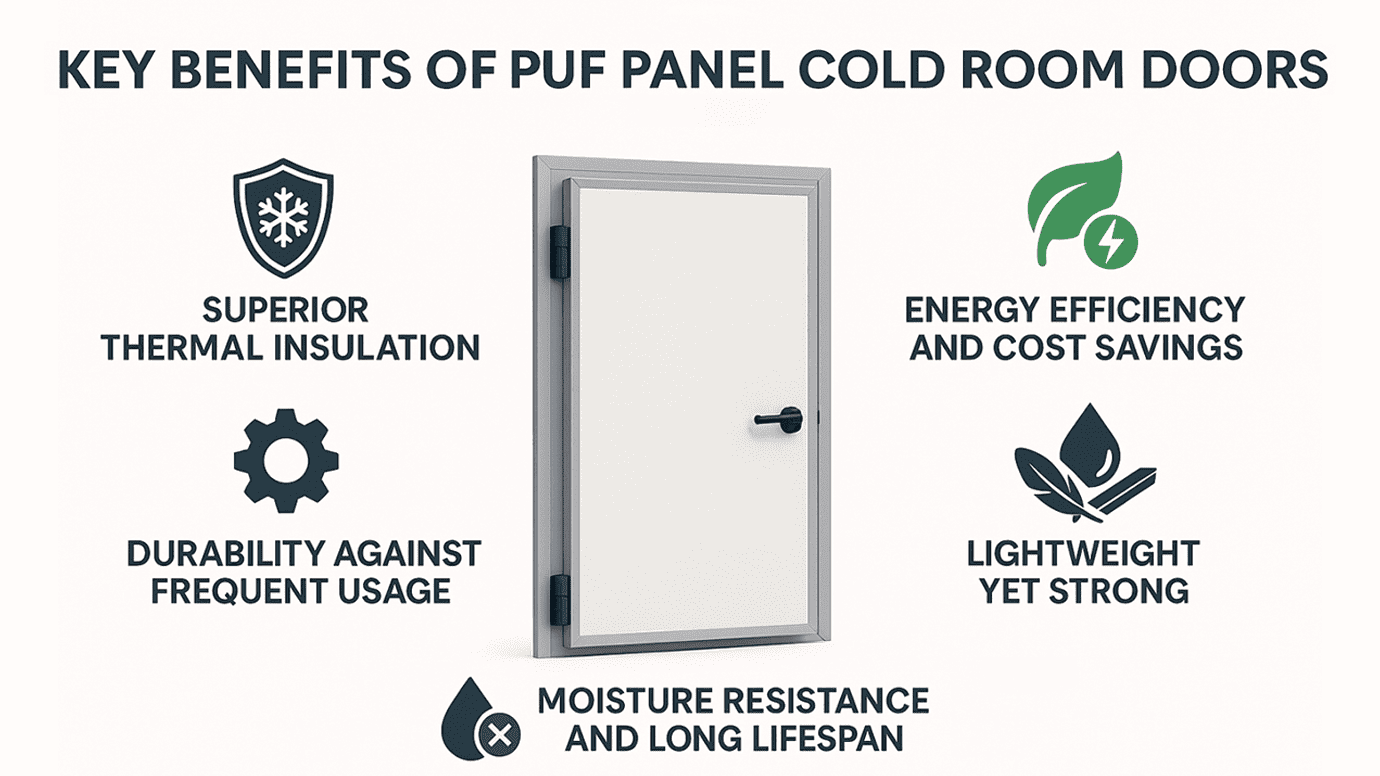

Why Choose PUF Panel Cold Room Doors?

When it comes to selecting the right cold room doors for a temperature-controlled facility, the choice of material plays a decisive role in overall performance. Among the many options available in the market, PUF (Polyurethane Foam) panel cold room doors stand out as the most reliable, efficient, and cost-effective solution. This is why leading industries prefer doors crafted from high-density PUF panels supplied by trusted cold room door suppliers.

1. Superior Thermal Insulation

The primary function of any cold storage door is to maintain temperature integrity. PUF panels are known for their low thermal conductivity, which ensures minimal heat transfer between the inside and outside environments. This superior insulation prevents unwanted temperature leakage, keeping perishable goods safe and reducing the strain on refrigeration systems.

2. Durability Against Frequent Usage

In cold storage facilities, doors are opened and closed multiple times a day. Ordinary doors wear out quickly, but PUF panel cold room doors are designed to withstand heavy usage. Their robust structure and high-density core provide long-lasting strength, making them ideal for industrial applications where reliability is essential.

3. Energy Efficiency and Cost Savings

Well-insulated cold storage doors significantly reduce energy consumption by minimizing cooling losses. This translates into lower electricity bills and a more sustainable operation. For businesses looking to optimize running costs, investing in energy-efficient PUF panel doors is a smart decision supported by experienced cold storage door manufacturers.

4. Lightweight Yet Strong

One of the unique advantages of PUF-insulated cold room doors is their lightweight construction without compromising strength. This makes them easier to operate, reduces wear on hardware such as hinges and handles, and ensures smooth functionality over time.

5. Moisture Resistance and Long Lifespan

Moisture infiltration is one of the biggest threats to cold storage infrastructure. PUF panel cold storage doors are highly resistant to moisture, preventing condensation, rust, or microbial growth. This not only protects the stored products but also extends the overall lifespan of the door.

In summary, choosing PUF panel cold room doors means investing in superior insulation, durability, and energy efficiency. Businesses that partner with reliable cold room doors manufacturers can be confident that their cold chain infrastructure is built for long-term success. With companies like Technopuff Solutions, a trusted name among top cold storage door manufacturers, industries gain access to doors that combine advanced engineering with unmatched performance—ensuring consistent temperature control and maximum cost savings.

Types of Cold Room Doors

Every cold storage facility has different operational needs, and the choice of cold room doors plays a crucial role in determining efficiency, safety, and performance. Leading manufacturers and trusted cold room door suppliers provide a variety of designs to suit small cold rooms, large industrial cold storage facilities, and specialized environments like pharmaceuticals or logistics hubs. Below are the most widely used types of cold storage doors:

Swing Cold Room Doors

Swing doors are among the most commonly used types of cold room doors, especially in small- to medium-sized storage facilities. They operate just like traditional doors but are designed with superior insulation to prevent temperature loss. Easy to install and simple to operate, these doors are perfect for applications where frequent access is required. Businesses prefer swing-style cold storage doors because they are cost-effective, durable, and available in both single-leaf and double-leaf designs.

Sliding Cold Room Doors

For larger cold storage facilities, sliding cold room doors are the ideal choice. Unlike swing doors, they open horizontally along a track, which saves space and makes them suitable for wide entry points. They also minimize air exchange during opening and closing, helping to maintain temperature stability more effectively. Many cold room doors manufacturers design sliding models with smooth gliding systems that ensure effortless operation even with frequent daily use. These doors are popular in large warehouses, distribution centers, and high-capacity storage plants.

Automatic Cold Room Doors

In high-traffic areas or large industrial setups, automatic cold room doors offer convenience and efficiency. Equipped with motion sensors or push-button systems, they eliminate the need for manual operation—reducing the chances of temperature leakage and improving workflow. Automatic cold storage doors are particularly beneficial in food processing plants and pharmaceutical facilities, where hygiene, speed, and accuracy are critical. Partnering with expert cold room door suppliers ensures that automatic systems are designed with reliable insulation and long-lasting performance.

Customized Cold Room Doors

Every industry has unique requirements, and sometimes standard designs don’t fully meet operational needs. That’s where customized cold room doors come in. Leading manufacturers and trusted cold room doors suppliers offer tailor-made solutions based on factors such as door size, type, operating mechanism, and insulation requirements. Whether it’s a combination of swing and sliding functions, additional safety features, or doors built for specialized industries like defense or floriculture, customization ensures that businesses get the perfect fit for their cold storage infrastructure.

From compact swing models to advanced automatic designs, cold room doors come in many variations to suit different industries and applications. Choosing the right type depends on factors like facility size, traffic flow, energy efficiency, and budget. By working with reliable cold room doors manufacturers, businesses can ensure they invest in high-quality cold storage doors that deliver maximum insulation, long-lasting durability, and seamless functionality.

Also Read: Clean Room Doors

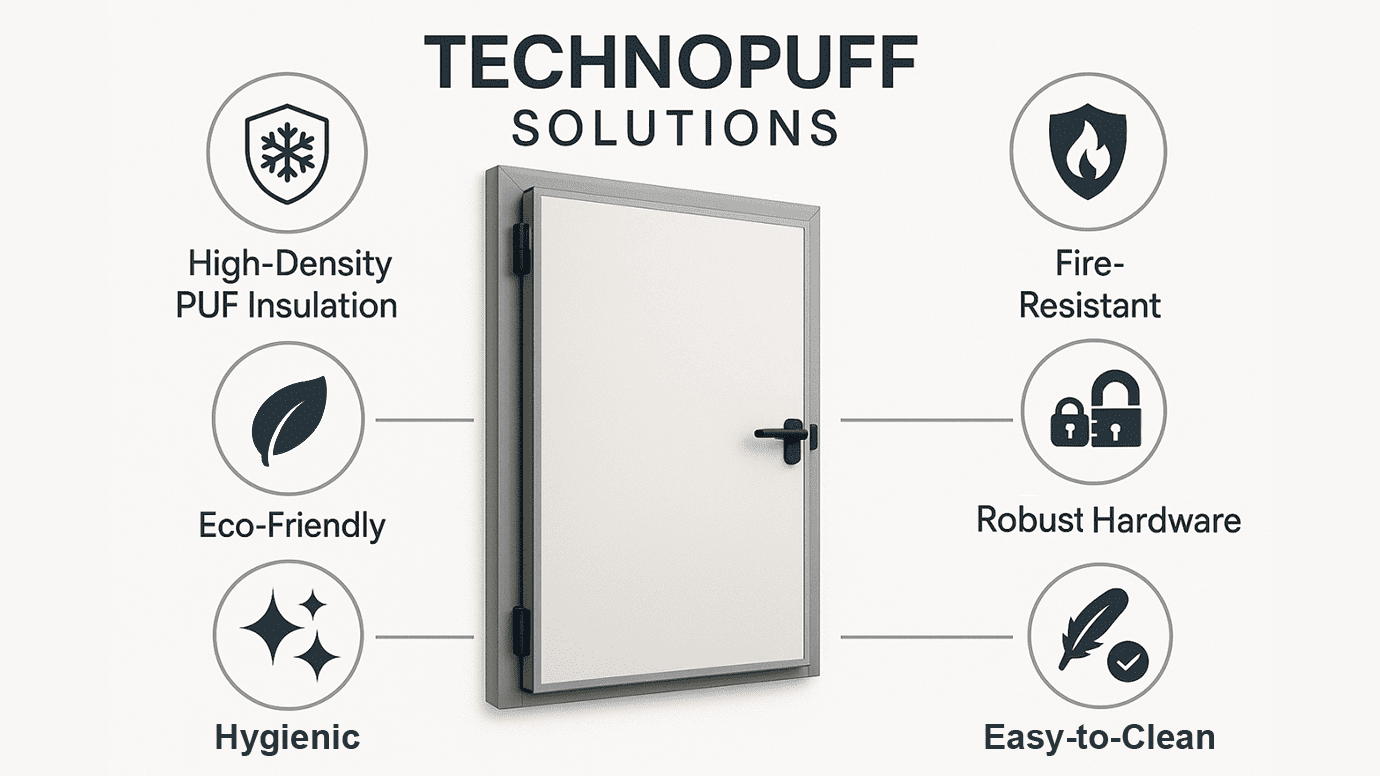

Key Features of Technopuff Cold Room Doors

At Technopuff Solutions, quality and innovation go hand in hand. As one of the most trusted cold room doors manufacturers in India, the company delivers doors that are not only durable but also engineered to meet the toughest industrial demands. Every product is designed with precision, ensuring maximum insulation, energy efficiency, and long-term performance. Here are the defining features that set us apart:

Manufactured with High-Density PUF Panels

The core of every Technopuff cold room door is made from high-density PUF (Polyurethane Foam) panels, which provide excellent thermal insulation. This ensures minimal temperature leakage, keeping the refrigeration system efficient while maintaining consistent internal conditions. For industries like food storage and pharmaceuticals, this translates into better product preservation and lower energy costs.

Fire-Resistant and Eco-Friendly Materials

Safety and sustainability are central to Technopuff’s design philosophy. All cold storage doors are crafted with fire-resistant materials that comply with safety norms, reducing risks in sensitive environments. Additionally, eco-friendly manufacturing processes make these doors a responsible choice for businesses committed to green practices.

Hygienic and Easy-to-Clean Surfaces

In industries such as food processing, dairy, and pharmaceuticals, hygiene is non-negotiable. Technopuff’s cold room doors are designed with smooth, easy-to-clean surfaces that resist bacterial growth and meet the highest hygiene standards. This makes them particularly suitable for sectors where cleanliness and contamination control are critical.

Robust Door Hardware for Long-Lasting Performance

Every cold storage door is fitted with heavy-duty hinges, handles, and locking systems designed for frequent usage. The robust hardware ensures reliability, smooth operation, and enhanced security, even in high-traffic environments. This durability reduces maintenance needs and guarantees long-term functionality.

Choosing Technopuff means choosing cold room doors that combine advanced insulation technology, robust engineering, and hygienic design—all backed by international quality standards. As one of the most dependable cold room doors manufacturers, Technopuff Solutions continues to set benchmarks in the cold storage industry, offering products that guarantee efficiency, safety, and durability for years to come.

You can also go through: Operation Theatre Doors

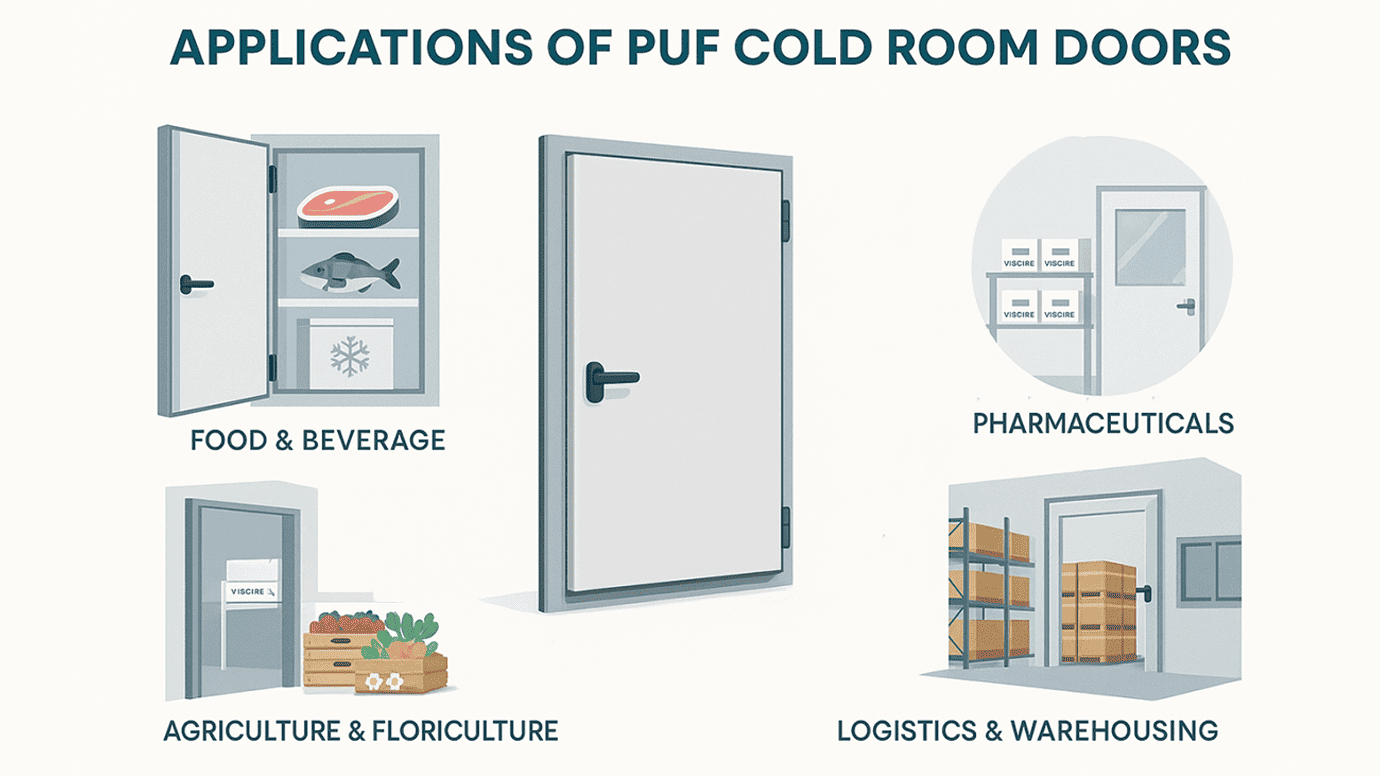

Applications of PUF Panel Cold Room Doors

The versatility of PUF panel cold room doors makes them an indispensable choice across multiple industries that demand strict temperature control, hygiene, and efficiency. Trusted cold room doors manufacturers design these doors with advanced insulation, durability, and moisture resistance, ensuring they perform seamlessly in challenging environments. Whether in food preservation, pharma storage, or large-scale logistics, high-quality cold storage doors are essential for protecting products and reducing energy costs.

Food & Beverage Industry

From dairy products to meat, poultry, seafood, and frozen foods, the food sector relies heavily on well-insulated cold room doors to preserve freshness and nutritional value. Any fluctuation in temperature can lead to spoilage and loss, making reliable cold storage doors vital for maintaining product quality. PUF panel doors provide superior insulation, easy operation, and hygienic surfaces, which are particularly important for processing units and frozen food distribution centers.

Pharmaceutical Storage & Clean Rooms

In the pharmaceutical sector, precision and hygiene are paramount. Medicines, vaccines, and biotechnological products require storage under strict temperature conditions. PUF panel cold room doors used in pharma cold chains and clean rooms ensure that temperature-sensitive products remain safe and effective. Reputable cold room doors manufacturers design these doors with smooth, easy-to-clean finishes to prevent microbial contamination—making them the ideal choice for healthcare and pharmaceutical industries.

Agriculture & Floriculture

Perishable agricultural goods such as fruits, vegetables, and flowers require controlled environments to extend their shelf life and preserve quality during transport and storage. PUF-insulated cold storage doors protect these sensitive products from heat and humidity fluctuations. For floriculture exporters, the use of reliable cold room doors is particularly critical, as even minor temperature changes can impact flower freshness and export quality.

Logistics & Warehousing

Modern supply chains depend on robust cold storage doors to handle high traffic while ensuring energy efficiency. Large warehouses, distribution centers, and logistics hubs need doors that can withstand frequent opening and closing without compromising insulation. PUF panel doors are designed for durability and smooth operation, making them the preferred choice for warehousing facilities. By sourcing doors from experienced cold room door manufacturers, logistics companies can ensure efficient operations and reduced cooling costs.

The wide range of applications highlights why PUF panel cold room doors are a smart investment across industries. Whether safeguarding frozen foods, pharmaceutical products, agricultural goods, or warehouse inventories, these doors deliver consistent performance, energy savings, and product protection. By working with trusted cold room doors manufacturers, businesses can ensure their infrastructure is equipped with world-class cold storage doors that meet international quality standards.

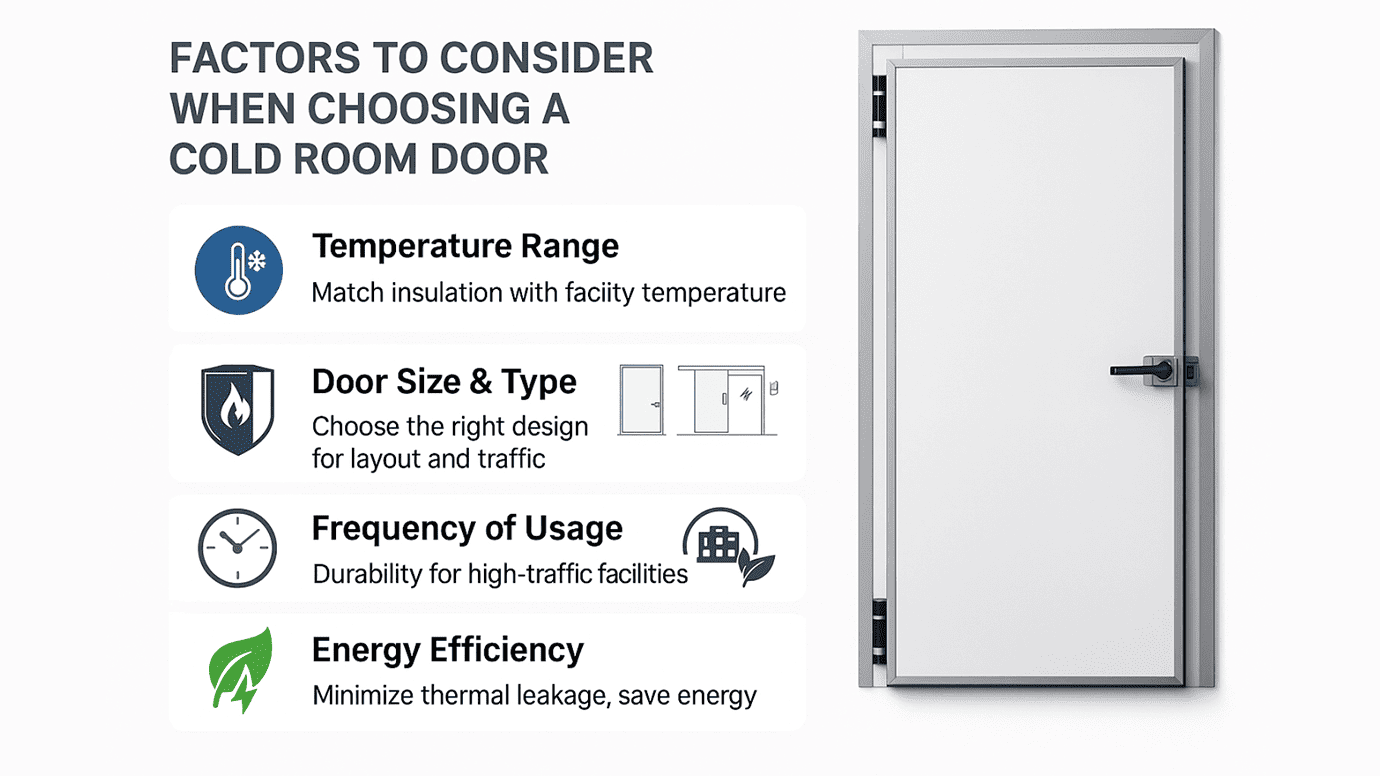

Choosing the Right Cold Room Door

Selecting the right cold room doors is a crucial decision that directly impacts the efficiency, safety, and overall performance of your cold storage facility. Since not all facilities have the same requirements, businesses must carefully evaluate a range of factors before making a purchase. Partnering with experienced cold room doors manufacturers ensures that you get doors tailored to your operational needs while meeting global quality standards. Below are the most important considerations:

Temperature Range

The first factor to consider is the temperature requirement of your facility. A cold storage unit designed for frozen foods requires doors with much stronger insulation compared to a facility maintaining moderately chilled environments. High-density PUF panel cold storage doors are engineered to handle both low and ultra-low temperatures effectively, ensuring minimal thermal leakage and stable conditions. Always consult reputed cold storage door manufacturers to select the right insulation thickness for your application.

Door Size & Type (Swing, Sliding, Automatic)

The size and type of cold room doors depend largely on the facility layout and traffic flow.

- Swing doors are best suited for smaller cold rooms or spaces with limited entry needs.

- Sliding doors are ideal for larger cold storage units where space optimization and wide access are critical.

- Automatic doors are recommended for high-traffic industrial setups where speed, hygiene, and convenience are essential.

Working with reliable cold storage doors suppliers ensures that you receive the right configuration, customized to fit your storage infrastructure.

Frequency of Usage

Another key aspect is how frequently the doors will be used. In high-traffic facilities such as warehouses or logistics hubs, cold storage doors must withstand constant opening and closing without losing insulation quality. Heavy-duty designs from experienced cold room doors manufacturers provide robust hardware and durable construction that can handle continuous usage while maintaining efficiency.

Energy Efficiency

Energy costs are among the biggest expenses in cold storage operations. Poorly designed or low-quality cold room doors can lead to temperature leaks, forcing refrigeration systems to work harder and consume more power. On the other hand, PUF-insulated cold storage doors are built to minimize thermal transfer, significantly lowering energy bills. Choosing doors from established cold storage door manufacturers helps businesses achieve long-term cost savings and improved sustainability.

The right cold room doors are not just about accessibility—they are about efficiency, safety, and long-term reliability. By considering factors such as temperature range, door type, usage frequency, and energy performance, businesses can make informed choices that protect their products and optimize operational costs. Partnering with trusted cold room door suppliers like Technopuff Solutions ensures that your facility is equipped with high-quality doors designed for lasting performance.

FAQs

A. Cold room doors are specially designed insulated doors used in temperature-controlled storage facilities. They play a critical role in preventing heat leakage, maintaining energy efficiency, and protecting stored products. Without high-quality cold storage doors, refrigeration systems struggle to maintain the right temperature, leading to higher energy bills and product spoilage.

A. PUF panel cold storage doors provide superior thermal insulation, which reduces temperature loss. This means refrigeration units work more efficiently, lowering energy consumption and electricity bills. Reputed cold storage door manufacturers design these doors with high-density insulation to maximize energy savings.

A. Industries like food and beverages, pharmaceuticals, agriculture, floriculture, logistics, and warehousing rely heavily on cold room doors. Trusted cold room door suppliers provide industry-specific solutions to ensure temperature integrity and compliance with safety standards.

A. PUF Panel Doors are insulated doors made with Polyurethane Foam (PUF) that provide superior thermal efficiency, durability, and energy savings. They are widely used in cold storage doors because they prevent temperature leakage and ensure long-term performance.

A. Yes. High-quality cold storage doors made with PUF panels are designed for frequent usage in industrial environments. Leading cold storage door manufacturers use robust hardware like heavy-duty hinges, handles, and locking systems to ensure long-lasting performance.

Conclusion

Investing in the right cold room doors is not just about enhancing accessibility—it is about ensuring long-term efficiency, durability, and cost savings for your business. With advanced PUF panel cold storage doors, companies can achieve superior thermal insulation, maintain temperature integrity, and significantly reduce energy consumption. These doors are engineered to withstand heavy usage, resist moisture, and deliver reliable performance across industries such as food processing, pharmaceuticals, agriculture, and logistics.

As one of the most trusted cold room doors manufacturers in India, Technopuff Solutions takes pride in offering doors that meet international quality standards while addressing the unique requirements of every client. Whether you need swing, sliding, automatic, or customized options, Technopuff provides solutions that combine cutting-edge technology with robust construction.

Backed by years of expertise as reliable cold room door suppliers, Technopuff Solutions ensures every product delivers maximum insulation efficiency, operational reliability, and long service life. From small-scale cold storage units to large industrial warehouses, businesses across sectors trust Technopuff for doors that safeguard their products and optimize running costs.

If you are looking for cold room doors that guarantee unmatched efficiency, strength, and savings, it’s time to partner with Technopuff Solutions. Contact our team today to explore fully customized solutions designed to meet your specific cold storage needs and elevate your facility’s performance to the next level. For more information regarding PUF Panels and doors and structures made from it, you can go to our Homepage.