PUF Corner Panels

In today’s fast-paced construction environment, PUF corner panel systems have become an essential component of energy-efficient and hygienic building design. Modern construction increasingly relies on PUF (Polyurethane Foam) panels due to their superior thermal insulation, lightweight structure, and rapid installation. These panels are widely used in industrial and commercial buildings where temperature control, cleanliness, and durability are critical.

Among all structural junctions, corners are the most vulnerable points in any insulated building. Poorly designed corner areas often lead to thermal bridging, air leakage, moisture ingress, and long-term energy loss. This is where specialized corner wall panel solutions play a vital role. A well-engineered wall panel corner ensures continuous insulation, structural integrity, and a seamless finish across intersecting walls.

PUF Corner Panels are specifically designed to eliminate insulation gaps at corners by maintaining uniform density and airtight sealing. These sandwich panel corner systems effectively prevent heat transfer, control condensation, and meet strict hygiene standards required in sensitive environments. Whether it is an internal corner PUF panel for clean spaces or an external PUF corner panels solution for industrial sheds, these panels significantly enhance building performance.

Industries such as cold storage, clean rooms, warehouses, and prefab buildings depend heavily on high-quality PUF panel corners to ensure energy efficiency, temperature stability, and long-term operational reliability. By addressing both thermal and structural challenges, PUF corner panels form the backbone of modern insulated construction systems.

What Are PUF Corner Panels?

These are specialized insulation components designed to strengthen and seal the most sensitive junctions in insulated structures—the corners. While flat insulated panels form the main wall surfaces, corners require a more precise and engineered solution. This is where a well-designed corner wall panel becomes essential to ensure thermal continuity, airtightness, and structural stability across the entire building envelope.

Difference between PUF Corner Panels and Flat PUF Panels

Standard flat PUF panels are ideal for straight walls but often require additional sealants and accessories at corners. In contrast, PUF Corner Sandwich Panels are factory-moulded to fit corner junctions perfectly. This ensures a seamless wall panel corner that eliminates thermal bridging and improves overall building performance. For comprehensive details, go through our dedicated page on PUF Panels.

Material Used in PUF Corner Panels

At the core of every corner PUF panel is high-density polyurethane foam, known for its excellent insulation properties and low thermal conductivity. The outer surfaces are finished with durable GI, PPGI, or SS sheets, which provide corrosion resistance, mechanical strength, and a hygienic finish suitable for industrial environments.

Panel Thickness and Insulation Values

PUF corner panels are available in multiple thickness options—typically ranging from 40 mm to 120 mm—depending on insulation requirements. Thicker panels offer higher thermal resistance, making them ideal for temperature-controlled spaces such as cold storage and clean rooms.

Role in Maintaining Continuous Insulation

A properly designed PUF panel corner plays a crucial role in maintaining uninterrupted insulation throughout the structure. By sealing the corner area effectively, PUF corner panels ensure consistent temperature control, reduced energy consumption, and long-term durability of insulated buildings.

Importance of Corner Insulation in PUF Panel Structures

Corner insulation plays a decisive role in the overall performance of insulated buildings. Even when high-quality wall panels are used, an improperly treated corner area can compromise thermal efficiency, structural strength, and hygiene. This makes the use of dedicated PUF corner panels essential in modern PUF panel structures, especially in temperature- and contamination-sensitive environments.

- Thermal Bridging at Joints: At an uninsulated corner area, heat easily escapes or enters through joints, creating thermal bridges. These weak points reduce insulation effectiveness and increase energy loss, directly impacting indoor temperature stability.

- Air and Moisture Leakage: Without proper corner sealing, gaps at the corners allow air and moisture to penetrate the structure. This infiltration affects internal conditions and accelerates insulation deterioration.

- Condensation Formation: Moisture entering through poorly sealed corner areas often leads to condensation. In cold environments, this can result in water accumulation, corrosion, and damage to the insulation system.

- Structural Weakness Over Time: Repeated exposure to moisture and temperature variation weakens the corners, reducing the overall durability of the building. Over time, this can lead to joint failure and increased maintenance costs.

- Hygiene Issues in Pharma and Food Units: In pharmaceutical and food-processing facilities, unsealed panel corner joints become breeding grounds for bacteria and contaminants. This directly affects compliance with hygiene and safety standards.

- How PUF Corner Panels Solve These Issues: PUF Corner Sandwich Panels are designed to maintain continuous insulation and airtight sealing at every junction. A properly installed corner PUF panel eliminates gaps, prevents thermal bridging, and ensures moisture resistance across all corner

- Energy Efficiency and Cost Savings: By reducing heat loss and minimizing HVAC load, PUF corner panels improve energy efficiency and deliver long-term operational cost savings, making them a critical component in high-performance insulated structures.

Types of PUF Corner Panels

Different construction environments require different types of PUF corner panels to ensure proper insulation, structural stability, and hygiene. Each corner wall panel is designed to address specific performance requirements at the corners, whether for interior partitions, external walls, or specialized controlled environments. Below are the major types of PUF Corner Panels used across industrial and commercial projects.

Internal PUF Corner Panels

These are installed at inside wall intersections where two insulated walls meet. These panels ensure seamless insulation at every corner within temperature-controlled spaces.

They are designed with smooth and uniform finishes, making each corner PUF panel easy to clean and maintain. This makes them highly suitable for:

- Clean rooms

- Food processing units

- Pharmaceutical production areas

- Cold storage interiors

The precision-engineered sandwich panel corner prevents dust accumulation and maintains hygienic standards in sensitive facilities.

External PUF Corner Panels

External corner wall panel systems are specifically designed for outdoor building corners. These provide structural reinforcement at exposed corner junctions.

Key features include:

- Weather-resistant GI / PPGI / SS coatings

- High resistance to UV exposure and corrosion

- Enhanced structural rigidity

- Strong bonding at the external panel corner

These panels are ideal for warehouses, industrial sheds, and prefab buildings where durability is critical.

By selecting the right PUF corner panels, builders can ensure optimal insulation, durability, and efficiency at every critical corner in the structure.

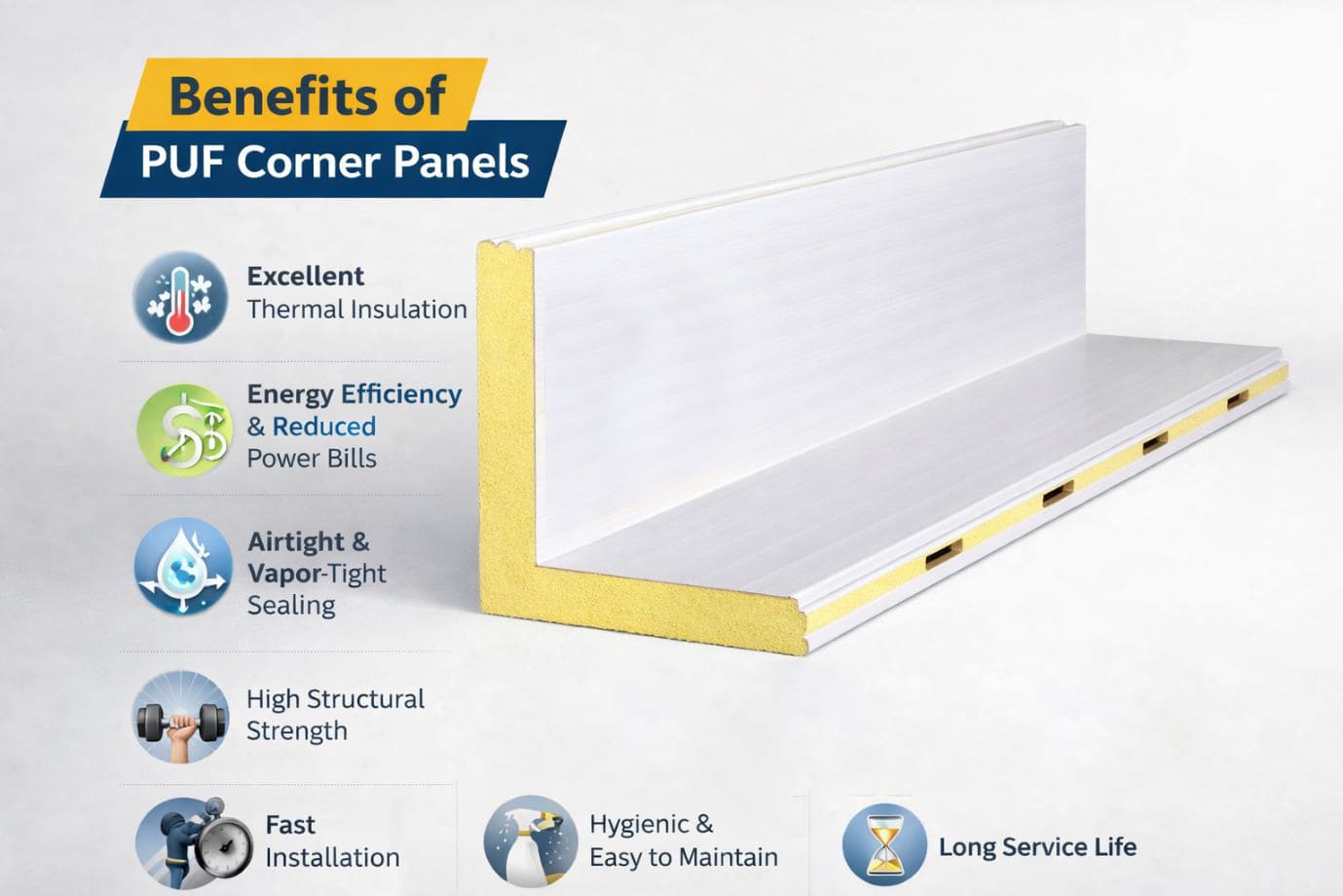

Key Benefits of Using PUF Corner Panels

The performance of any insulated structure largely depends on how well its corners are sealed and reinforced. Since the wall panel corner is a critical junction, using high-quality PUF corner panels ensures durability, energy efficiency, and hygiene compliance. A well-designed corner wall panel strengthens the building envelope and eliminates common weaknesses found at every corner.

- Excellent Thermal Insulation: One of the biggest advantages of PUF Corner Sandwich Panels is their superior thermal insulation. The high-density polyurethane core in each PUF corner panels minimizes heat transfer across the corner, preventing thermal bridging and maintaining consistent internal temperatures.

- Energy Efficiency & Reduced Power Bills: By sealing the wall panel corner effectively, these reduce the load on HVAC systems. Less heat gain or loss at each panel corner means lower energy consumption, resulting in significant long-term savings on electricity bills.

- Airtight & Vapor-Tight Sealing: A properly engineered corner wall panel ensures airtight and vapor-tight sealing. This prevents air leakage and moisture infiltration at the corner, reducing condensation issues in cold storage and clean room environments.

- High Structural Strength: Every corner PUF panel is designed to add rigidity at structural intersections. Reinforced PUF corner panels strengthen the corner, improving overall stability and resistance to environmental stress.

- Fast Installation: Unlike conventional construction methods, PUF corner panels are prefabricated for quick assembly. This allows faster project completion and reduces labor costs at each corner.

- Hygienic & Easy to Maintain: The smooth finish of a corner wall panel prevents dust accumulation at the corner. This makes cleaning easier and supports hygiene compliance in pharma and food-processing industries.

- Long Service Life: With corrosion-resistant outer sheets and durable insulation cores, PUF corner panels provide long-term reliability and minimal maintenance requirements.

PUF Corner Panels vs Traditional Brick/Concrete Corners

- Insulation Performance: PUF corner panels provide continuous insulation at every corner, while brick or concrete corners require additional insulation layers.

- Energy Efficiency: A sealed corner PUF panel reduces heat loss significantly compared to conventional masonry corners.

- Installation Speed: PUF Corner Sandwich Panels are factory-made and install quickly, whereas brick or concrete corners require longer construction time.

- Hygiene Standards: Smooth sandwich panel corner surfaces are easy to clean, unlike porous brick or concrete that can trap dust and contaminants.

- Maintenance & Longevity: Properly installed PUF corner panels offer lower maintenance and better durability than traditional construction corners.

Also Read: Brick and Mortar vs PUF Panels

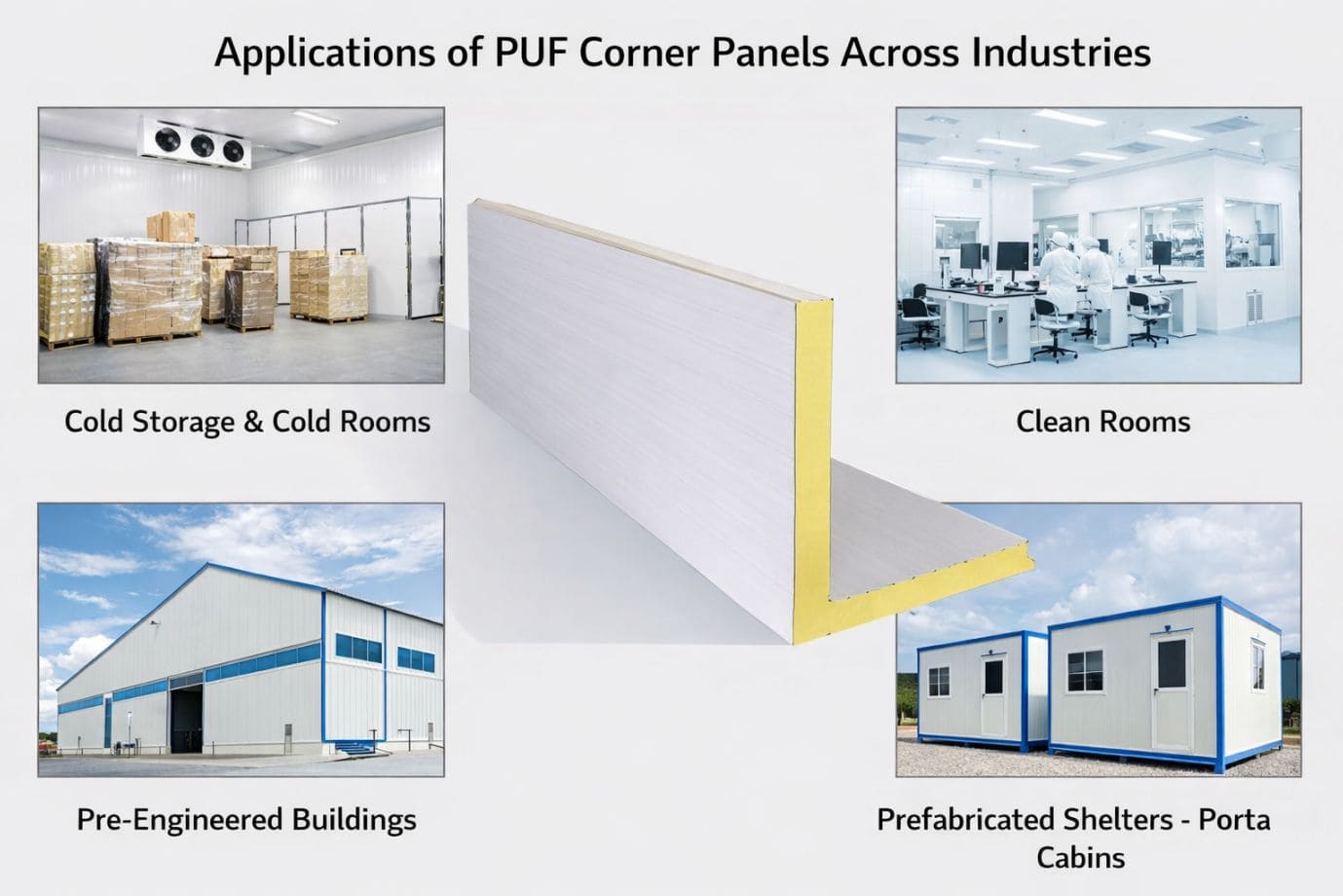

Applications of PUF Corner Panels across Industries

Different industries require precise insulation solutions to maintain temperature control, hygiene, and structural stability. Since the wall panel corner is one of the most sensitive areas in insulated construction, high-quality PUF corner panels are widely used across sectors that demand reliable performance and long-term durability.

- Cold Storage & Cold Rooms: In temperature-controlled environments, cold storage PUF corner panels play a crucial role in preventing heat transfer at every corner. A properly sealed corner ensures stable internal temperatures, reduces energy loss, and protects perishable goods from spoilage. For more information, you can read our dedicated page on Cold Storage.

- Clean Rooms (Pharma, Biotech labs): In pharmaceutical, biotech, and electronics industries, clean room insulated corners are essential for contamination control. A smooth and airtight corner wall panel prevents dust accumulation at the corner, ensuring compliance with strict hygiene and regulatory standards. You can also read our detailed blog on PUF Panel Clean Rooms for more information.

- Food Processing Plants: Food-grade facilities require hygienic and moisture-resistant insulation systems. A well-installed corner PUF panel eliminates gaps at the corner, reducing condensation risks and maintaining sanitation standards in processing areas.

- Warehouses & Logistics Hubs: Large industrial storage spaces benefit from durable PUF Corner Sandwich Panels that strengthen the corner while maintaining insulation efficiency. These panels enhance structural stability and energy performance in high-volume facilities.

- Pre-Engineered Buildings (PEB): In PEB structures, precision-engineered PUF corner panels ensure seamless insulation at every corner, supporting fast construction and long-term durability. For comprehensive details, you can explore our page on Pre-Engineered Buildings (PEBs).

- Prefabricated Shelters & Porta Cabins: For modular structures such as shelters and porta cabins, a high-quality corner wall panel provides consistent insulation and structural support, making PUF Corner Sandwich Panels ideal for portable and prefabricated applications. Detailed information can be seen in our dedicated page on Porta Cabins.

Maintenance & Longevity of PUF Corner Panels

When investing in insulation systems, buyers often evaluate durability and maintenance requirements. High-quality corner panels are engineered to provide long-term reliability while minimizing upkeep. A properly designed corner wall panel not only strengthens the corner but also ensures sustained insulation performance over years of operation.

Low Maintenance Requirements:

Modern PUF Corner Sandwich Panels are manufactured with durable outer sheets and a stable insulation core. This makes each corner resistant to physical damage and environmental stress, reducing the need for frequent repairs or replacements.

Easy Cleaning Procedures:

The smooth surface of a corner PUF panel allows easy cleaning with mild detergents and non-abrasive materials. In facilities where hygiene is critical, maintaining a clean corner ensures compliance with safety and sanitation standards.

Resistance to Corrosion & Moisture:

A high-quality corner wall panel is typically coated with GI, PPGI, or SS finishes that protect the corner from corrosion. Additionally, the sealed structure of the panel corner prevents moisture penetration, minimizing condensation and long-term structural damage.

Expected Lifespan in Industrial Environments:

With proper installation and routine inspections, corner panels can deliver a lifespan of 15–25 years in industrial settings. The strength and durability of these panels ensure consistent insulation performance, making them a dependable solution for demanding environments.

Why Choose Technopuff Solutions for PUF Corner Panels?

Choosing the right manufacturer for PUF corner panels directly impacts insulation performance, durability, and long-term operational costs. At every corner, precision and quality matter. Technopuff Solutions stands out as a trusted partner for delivering high-performance PUF corner panels tailored to industrial requirements.

- Precision-Engineered Manufacturing: Technopuff uses advanced production technology to ensure accurate shaping and bonding at every corner. Each corner PUF panel is manufactured with uniform density to eliminate thermal gaps and structural weaknesses.

- High-Quality Raw Materials: Only premium-grade polyurethane foam is used to manufacture corner wall panel Outer finishes such as GI, PPGI, and SS sheets enhance the durability of every sandwich panel corner, ensuring resistance to corrosion and environmental stress.

- Customization as Per Project Requirements: Every project has unique insulation demands. Technopuff offers customized PUF corner panels based on:

- Thickness requirements (40mm–120mm and above)

- Required corner angles (90°)

- Surface finishes and coatings

- Density specifications for temperature-controlled environments

This ensures a perfect fit at each corner.

- Industry-Specific Expertise: Technopuff delivers specialized PUF corner panels for:

- Cold storage facilities

- Clean rooms and pharma units

- Warehouses and logistics hubs

- Pre-engineered buildings (PEB)

- Prefabricated shelters and porta cabins

Each panel corner solution is designed to meet industry compliance standards.

Also explore our comprehensive page on Prefabricated Shelters.

- Superior Thermal & Structural Performance: Technopuff’s corner PUF panel systems maintain continuous insulation across every corner, reducing HVAC load and preventing condensation. The result is enhanced energy efficiency and long-term cost savings.

- Timely Delivery & Technical Support: From manufacturing to installation guidance, Technopuff ensures smooth execution. Their team provides expert assistance to guarantee proper alignment at every corner wall panel

- Long-Term Reliability: With durable construction and strict quality checks, Technopuff’s PUF corner panels offer extended service life, low maintenance, and consistent insulation performance even in demanding industrial environments.

FAQs

A. PUF corner panels are specially designed insulated panels used to seal and reinforce building corners where two insulated walls meet. They are important because they prevent thermal bridging, air leakage, and moisture infiltration, ensuring better energy efficiency and structural stability.

A. A corner wall panel improves insulation performance by maintaining continuous thermal coverage at wall intersections. It eliminates gaps at corners, reducing heat transfer and enhancing overall building energy efficiency.

A. Proper sealing at a wall panel corner is necessary to prevent air leakage, condensation, and structural weakness. A well-installed insulated corner ensures long-term durability and temperature stability in controlled environments.

A. An unsealed panel corner can lead to thermal bridging, moisture ingress, condensation buildup, and increased HVAC load. Over time, this may reduce insulation efficiency and increase maintenance costs.

A. A sandwich panel corner provides continuous insulation with a polyurethane core, unlike traditional masonry corners that require additional insulation layers and sealing methods to achieve similar performance.

A. A corner PUF panel is commonly used in cold storage units, clean rooms, food processing plants, warehouses, and prefab structures where airtight and hygienic insulation is essential.

Conclusion

In modern insulated construction, performance is defined by how well every joint and junction is sealed—especially the wall panel corner. High-quality PUF corner panels play a critical role in eliminating thermal bridging, preventing air leakage, and maintaining structural integrity at each corner. Whether used in cold storage facilities, clean rooms, food processing plants, warehouses, or pre-engineered buildings, a properly engineered corner wall panel ensures consistent insulation and long-term durability.

By providing seamless bonding at every corner, PUF corner panels enhance energy efficiency and significantly reduce HVAC load. The precision design of each corner PUF panel supports airtight sealing, moisture resistance, and hygienic conditions in sensitive industrial environments. This not only improves operational stability but also lowers maintenance and energy costs over time.

As industries continue to prioritize sustainable and energy-efficient construction, investing in reliable PUF corner panels becomes a strategic decision rather than just a structural choice. The right corner wall panel solution strengthens the building envelope while delivering measurable long-term value.

For projects that demand precision, durability, and customized insulation performance, it is always wise to consult experts who understand your specific requirements. Choose Technopuff Solutions to ensure optimal insulation performance at every critical panel corner of your structure.

For more information, go to our Homepage.