Clean Room Doors

In industries where hygiene, precision, and controlled environments are non-negotiable, clean rooms play a critical role. From pharmaceutical production to electronics assembly and biotech research, these specialized environments are designed to minimize contamination and maintain strict air quality standards. Among the many components that make up a clean room, clean room doors are often underestimated—yet they serve as the first line of defense in maintaining air pressure, temperature control, and a dust-free atmosphere.

A well-engineered cleanroom door not only ensures airtight sealing but also supports smooth movement of personnel and equipment without compromising the sterile environment. The right clean room door design can significantly enhance the performance and efficiency of a controlled facility, making it a vital investment for any organization that prioritizes quality and compliance.

As a trusted clean room door manufacturer, Technopuff Solutions brings innovation and reliability to this crucial element of clean room infrastructure. Our pharmaceutical clean room door solutions are crafted using advanced PUF (Polyurethane Foam) panels, which provide superior insulation, lightweight durability, and exceptional hygiene. These PUF panel clean room doors are specifically engineered to meet the stringent requirements of modern industries, offering an ideal blend of functionality, safety, and long-term performance.

By combining cutting-edge materials with precision manufacturing, we deliver clean room doors that not only protect sensitive operations but also reflect a modern approach to clean room construction.

What Are Clean Room Doors?

Clean room doors are specially engineered entry systems designed to maintain the integrity of controlled environments by preventing contamination and ensuring stable air pressure. Unlike conventional doors, a cleanroom door is built to provide airtight sealing, thermal insulation, and smooth surfaces that are easy to clean, ensuring that dust, microbes, and airborne particles are kept out. Their primary function is to safeguard the sterile and controlled conditions of the facility, making them an essential part of clean room infrastructure.

The clean room door design varies depending on industry needs but typically includes features like flush surfaces, antimicrobial finishes, and high durability. A well-structured design not only enhances operational efficiency but also supports compliance with stringent industry standards such as GMP, ISO, and FDA.

As an experienced clean room door manufacturer, Technopuff Solutions produces doors that are specifically tailored to meet the unique demands of multiple industries. In the pharmaceutical sector, a pharmaceutical clean room door ensures a contamination-free environment for medicine and vaccine production. In biotech facilities, it supports sensitive research and genetic studies by maintaining strict environmental control. Electronics and semiconductor industries rely on clean room doors to protect microchips and delicate circuitry from dust particles that can compromise performance. Healthcare and laboratory environments also require specialized cleanroom doors to keep testing, diagnostic, and surgical areas sterile. Even the food processing industry uses these doors to ensure hygiene and safety in packaging and storage areas.

Whether in pharmaceuticals, healthcare, or high-tech manufacturing, clean room doors act as a protective barrier that maintains cleanliness, prevents cross-contamination, and upholds the quality of sensitive processes.

Also Read: Operation Theatre Doors

Why PUF Panels Are Ideal for Clean Room Doors

When it comes to maintaining controlled environments, the choice of material for clean room doors is just as important as the design. One of the most advanced solutions in this domain is PUF (Polyurethane Foam) technology. PUF is a high-performance insulating material made by combining polyol and isocyanate, which creates a rigid foam core. This core is sandwiched between metal sheets to form panels that are lightweight, strong, and highly efficient.

As a leading clean room door manufacturer, Technopuff Solutions leverages this technology to create clean room doors that not only meet but exceed the stringent demands of industries like pharmaceuticals, biotech, and electronics. The integration of PUF panels into clean room door design offers several unmatched benefits:

High Thermal Insulation

PUF panels provide excellent insulation, helping clean room doors maintain stable internal temperatures. This is especially critical in pharmaceutical environments where a pharmaceutical clean room door must ensure precise temperature control to protect medicines and sensitive formulations.

Lightweight Yet Durable

Despite being lightweight, PUF panels are structurally strong, allowing clean room doors to withstand heavy usage without warping or bending. This makes them ideal for high-traffic areas in labs, hospitals, and clean manufacturing facilities.

Smooth, Hygienic Surface

The flat, seamless finish of PUF-based clean room doors ensures easy cleaning and minimal dust accumulation. This hygienic surface is vital for industries like healthcare and biotech, where sterility cannot be compromised.

Energy Efficiency

By minimizing heat transfer, PUF panels reduce energy consumption in clean rooms. An efficient clean room door design directly lowers operational costs while supporting sustainability goals.

Acoustic Insulation

PUF panel clean room doors also act as sound barriers, reducing noise transfer between rooms. This is particularly valuable in laboratories and research centers that demand concentration and quiet operation.

Incorporating PUF technology into clean room doors ensures a combination of durability, performance, and compliance with international standards. Whether it’s a pharmaceutical clean room door for sterile production or a modular cleanroom door for research labs, PUF panels deliver unmatched reliability and value. You can also read our detailed blog on PUF Panel Doors for more information about different doors.

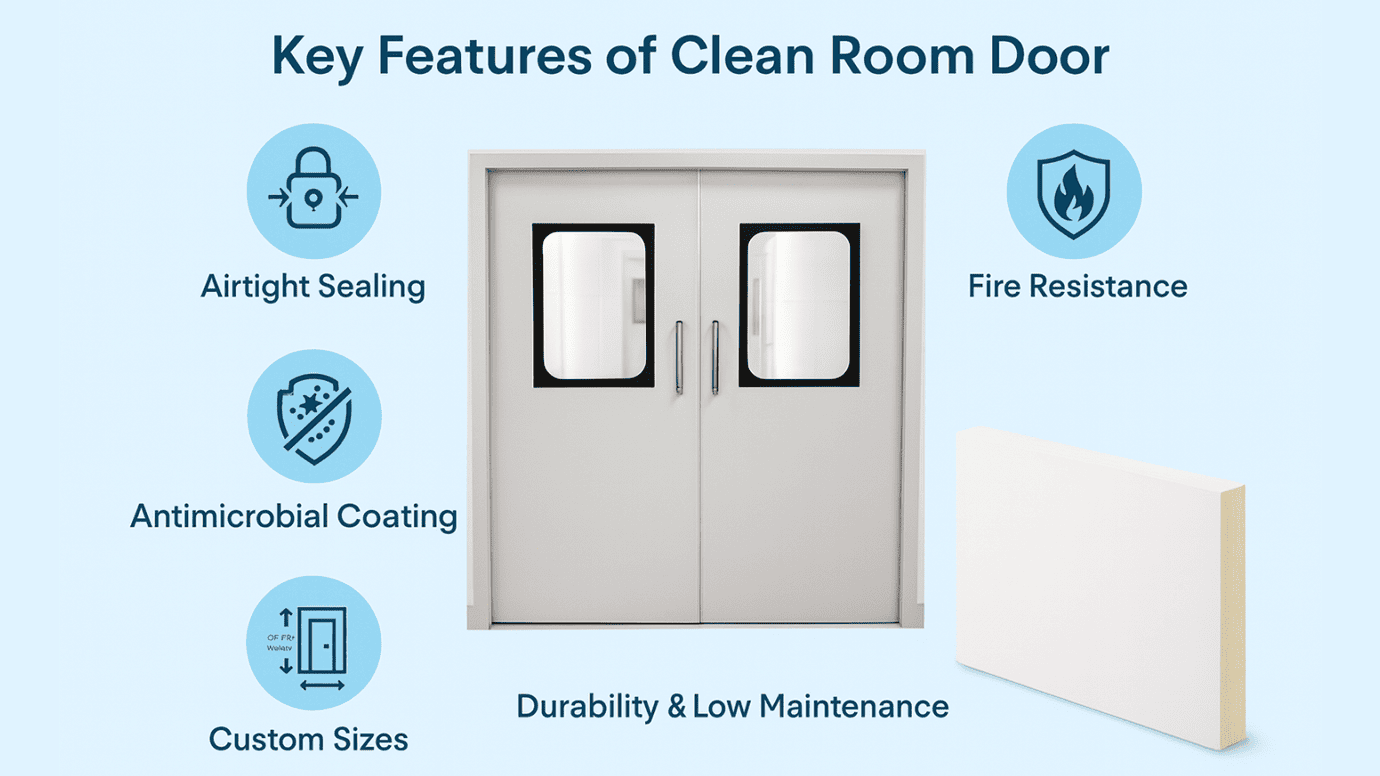

Key Features of Our Clean Room Doors

At Technopuff Solutions, we understand that clean room doors are not just entry points—they are critical elements in maintaining contamination-free environments. As a trusted clean room door manufacturer, we design every door with precision, innovation, and compliance in mind. Our clean room doors are engineered using high-quality PUF panels and advanced fabrication techniques, offering unmatched reliability across industries such as pharmaceuticals, biotech, electronics, and healthcare.

Here are the standout features of our clean room door design:

Airtight Sealing for Controlled Environments

Our clean room doors are designed to provide complete airtight sealing. This prevents air leakage and cross-contamination, ensuring stable pressure levels and optimal environmental conditions inside controlled facilities.

Antimicrobial Coatings for Hygiene

Hygiene is paramount in pharmaceutical and biotech industries. That’s why every pharmaceutical clean room door we produce is coated with antimicrobial finishes that resist bacterial growth, making them ideal for sterile environments where cleanliness is non-negotiable.

Fire Resistance and Safety Compliance

Safety is as important as sterility. Our clean room doors are fire-resistant and fully compliant with international safety standards, offering peace of mind for industries where protection and compliance go hand in hand.

Customizable Sizes and Thickness (50 mm to 80 mm)

Recognizing that each project has unique needs, we offer clean room doors in customizable sizes and thicknesses ranging from 50 mm to 80 mm. This flexibility allows our clean room door design to be adapted perfectly for pharmaceutical, healthcare, and industrial applications.

Long-Lasting and Low Maintenance

Durability is built into every clean room door we manufacture. Our doors are corrosion-resistant, sturdy, and require minimal maintenance, making them a cost-effective choice for long-term operations.

As a specialized clean room door manufacturer, Technopuff Solutions focuses on delivering doors that combine airtight performance, safety, hygiene, and durability. Whether you need a pharmaceutical clean room door for sterile drug production or a modular door for advanced laboratories, our solutions are engineered to exceed expectations.

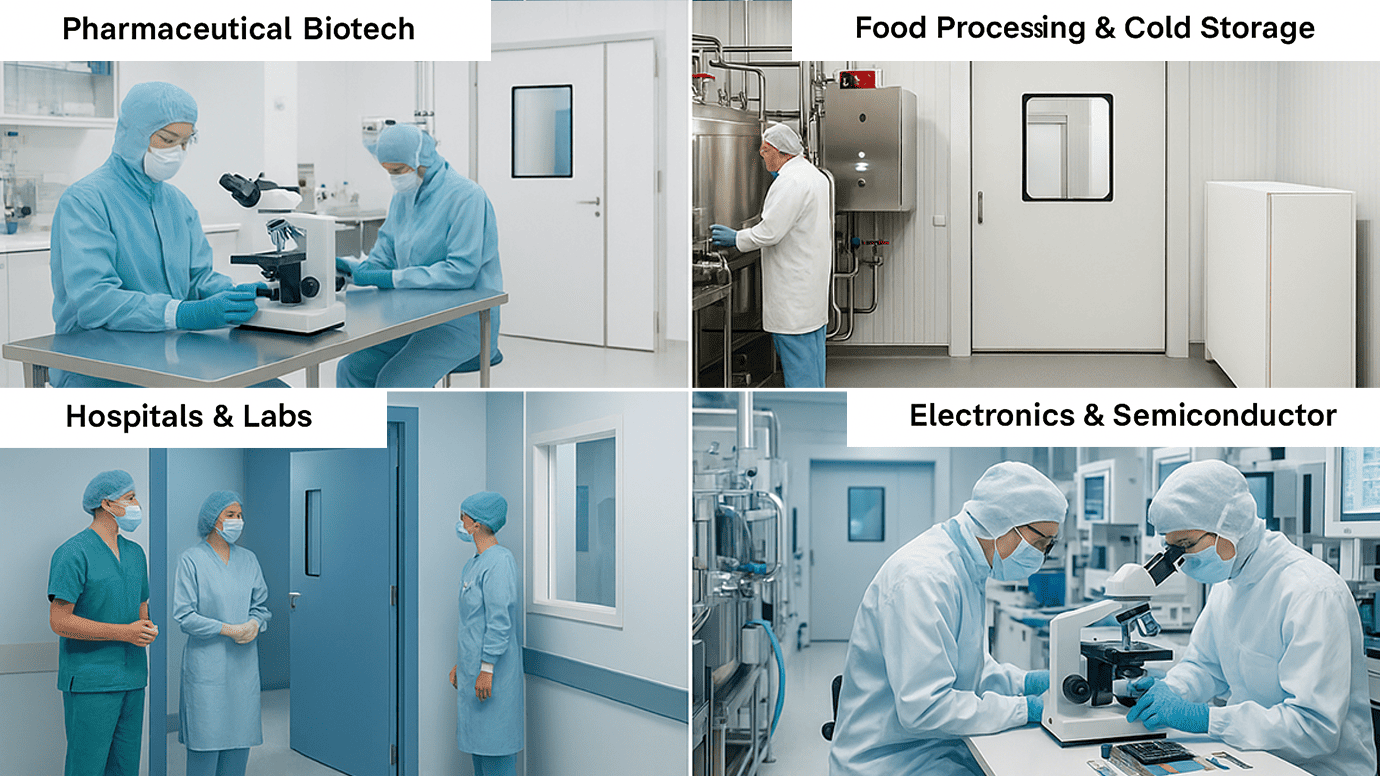

Applications of Clean Room Doors

The role of clean room doors extends far beyond being simple entry points. They are critical to ensuring environmental control, contamination prevention, and operational efficiency across a wide range of industries. At Technopuff Solutions, as a leading clean room door manufacturer, we design doors that are tailored to meet the unique requirements of each sector. Our advanced clean room door design, crafted from PUF panels, ensures airtight performance, hygiene, and durability, making them suitable for multiple applications.

Pharmaceutical & Biotech Industries

In pharmaceutical manufacturing and biotech research, even the smallest contamination can compromise product safety and research accuracy. That’s why a pharmaceutical clean room door is built to maintain sterile conditions by ensuring airtight sealing, antimicrobial protection, and compliance with GMP and FDA standards. From vaccine production units to biotech labs, our clean room doors are trusted for their reliability and performance.

Food Processing & Cold Storage

Maintaining hygiene and temperature control is vital in food processing facilities and cold storage units. Our PUF-based clean room doors provide excellent insulation to regulate temperature, reduce energy loss, and prevent microbial contamination. Whether it’s a dairy plant, frozen food warehouse, or packaging facility, our specialized clean room door design helps preserve quality and freshness.

Hospitals, Labs, and Diagnostic Centers

Healthcare environments demand strict sterility and infection control. Our clean room doors are designed with smooth, hygienic finishes and antimicrobial coatings, making them easy to clean and maintain. From operating theaters to diagnostic centers, a well-engineered pharmaceutical clean room door ensures that sensitive areas remain contamination-free, safe, and compliant with healthcare standards.

Electronics and Semiconductor Industries

Electronics and semiconductor manufacturing require dust-free, controlled environments to protect delicate components. Our clean room doors provide airtight sealing and electrostatic resistance, safeguarding microchips, circuits, and precision equipment. With a specialized clean room door design, we help ensure that production facilities achieve the highest standards of quality and efficiency.

At Technopuff Solutions, every cleanroom door we manufacture is tailored to the specific needs of these industries, combining functionality with durability. Whether it’s pharmaceuticals, food safety, healthcare, or high-tech electronics, our expertise as a clean room door manufacturer ensures that our clients receive solutions that meet international benchmarks of performance and safety.

Advantages of Choosing Technopuff Solutions

When it comes to clean room doors, choosing the right partner is just as important as selecting the right product. At Technopuff Solutions, we go beyond being a typical clean room door manufacturer—we deliver reliability, innovation, and long-term value with every solution. Our expertise in clean room door design and PUF panel technology makes us a trusted choice for industries that demand the highest levels of hygiene, safety, and performance.

Here’s why businesses across pharmaceuticals, healthcare, electronics, and food processing prefer Technopuff Solutions:

In-House Manufacturing with Quality Checks

We design and produce our clean room doors in-house, ensuring complete control over quality at every stage of manufacturing. From raw material selection to final inspection, each cleanroom door undergoes stringent testing to meet international standards. This commitment to quality makes our pharmaceutical clean room door solutions reliable and compliant with industry regulations.

Cost-Effective Yet Premium Solutions

Our mission is to make world-class clean room doors accessible without compromising on quality. By optimizing production and using advanced PUF panel technology, we offer cost-effective solutions that deliver premium performance. This balance of affordability and durability ensures our clients get maximum value from every cleanroom door they invest in.

Timely Delivery and Installation Support

We understand the importance of timelines in critical industries like pharma and electronics. That’s why we ensure not only timely delivery of clean room doors but also provide professional installation support. A precise clean room door design, combined with efficient project management, helps our clients achieve seamless integration into their facilities without delays.

Trusted by Industry Leaders

Our reputation as a reliable clean room door manufacturer is reinforced by the trust placed in us by leading organizations across various sectors. Whether it’s supplying a pharmaceutical clean room door for sterile production or a modular door for advanced research facilities, our products have consistently exceeded client expectations.

By choosing Technopuff Solutions, you gain more than just high-quality clean room doors—you gain a partner committed to innovation, precision, and customer success. With our expertise in clean room door design and decades of combined industry knowledge, we stand as a dependable choice for businesses that demand excellence.

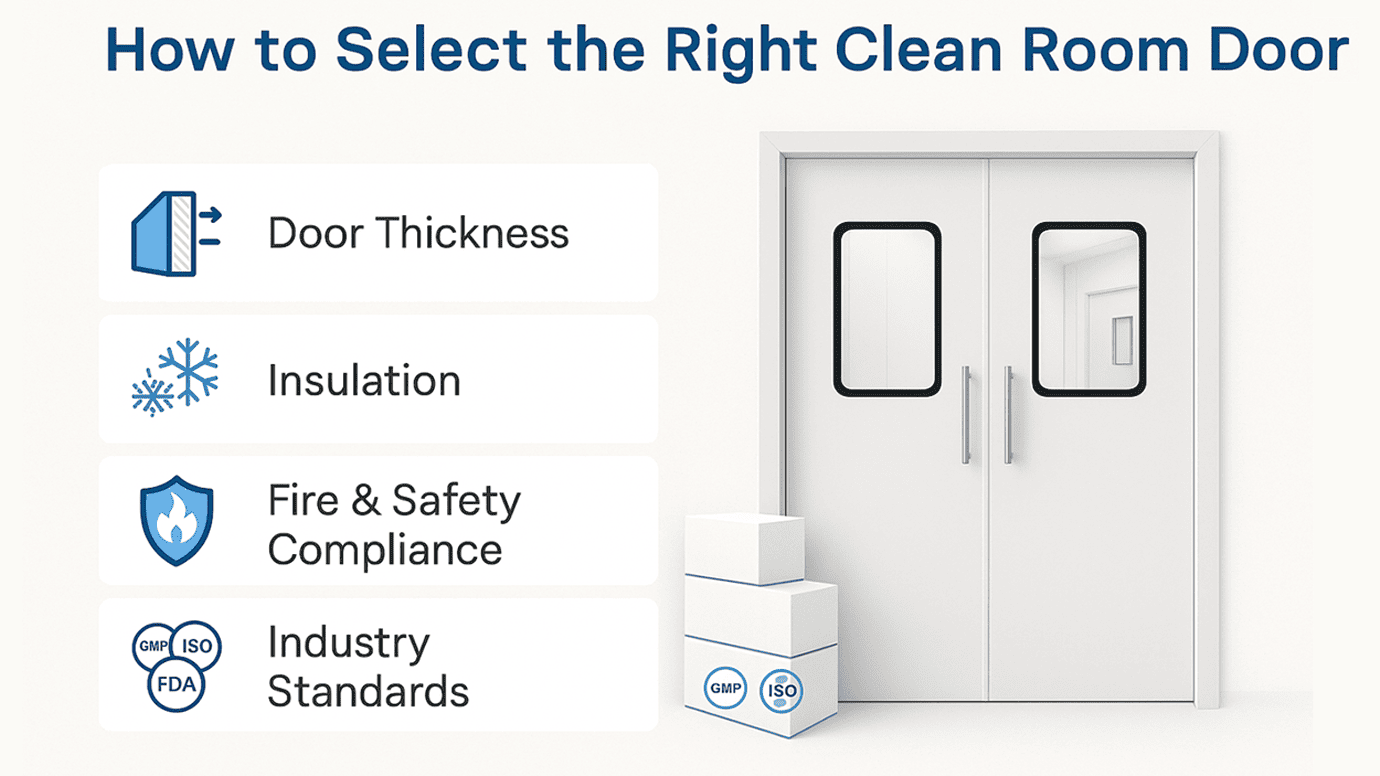

How to Select the Right Clean Room Door

Choosing the right clean room doors is a critical step in ensuring that your controlled environment meets performance, safety, and compliance requirements. A poorly chosen door can compromise air pressure, hygiene, and even regulatory approval. That’s why working with an experienced clean room door manufacturer like Technopuff Solutions can make all the difference. Our expertise in clean room door design ensures that every client receives a door tailored to their unique operational needs.

When selecting the perfect cleanroom door, here are the key factors to consider:

Door Thickness

The thickness of clean room doors directly impacts their insulation, strength, and durability. Depending on your facility’s requirements, Technopuff Solutions offers customized thickness options to deliver airtight sealing and reliable performance. For a pharmaceutical clean room door, precise thickness is crucial to maintaining sterile conditions in sensitive production areas.

Level of Insulation Required

Insulation is one of the most important aspects of clean room door design. PUF panel-based clean room doors provide superior thermal and acoustic insulation, helping maintain consistent internal temperatures and preventing noise transfer between rooms. This feature is particularly valuable in pharmaceutical and biotech facilities, where even minor environmental fluctuations can disrupt processes.

Fire & Safety Compliance

Every industry places emphasis on safety, and clean room doors must be no exception. A high-quality cleanroom door should comply with fire resistance standards to protect both personnel and assets. As a leading clean room door manufacturer, we ensure that our doors are built with fire-resistant materials while still maintaining airtightness and durability.

Industry-Specific Standards (GMP, ISO, FDA, etc.)

Different industries have different compliance requirements. A pharmaceutical clean room door must meet GMP and FDA standards, while healthcare and labs may demand ISO-certified solutions. At Technopuff Solutions, we design clean room doors that adhere to these global benchmarks, ensuring regulatory approval and peace of mind for our clients.

Selecting the right clean room doors requires balancing functionality, compliance, and durability. With Technopuff Solutions’ expertise in advanced clean room door design, you can be confident that every cleanroom door we manufacture will meet your industry’s most demanding standards.

FAQs

A. Clean room doors are specially designed entry systems that maintain controlled environments by preventing contamination and ensuring air-tight sealing. They are crucial in industries like pharmaceuticals, electronics, and healthcare, where sterility and precision are essential.

A. A pharmaceutical clean room door is engineered with antimicrobial coatings, airtight sealing, and smooth, easy-to-clean surfaces to meet GMP and FDA standards. Unlike regular doors, it is specifically designed to maintain sterile and contamination-free environments.

A. Clean room doors are used in multiple industries such as pharmaceuticals, biotechnology, food processing, electronics, healthcare, and diagnostic labs. A pharmaceutical clean room door, for example, helps maintain sterility during medicine and vaccine production.

A. PUF panels provide excellent insulation, durability, and hygiene. When integrated into clean room doors, they offer thermal efficiency, acoustic insulation, and smooth surfaces that are easy to clean—making them the preferred choice of any quality clean room door manufacturer.

A. Yes. At Technopuff Solutions, every cleanroom door is customizable in terms of size and thickness (50 mm to 80 mm), ensuring they meet the specific requirements of your facility without compromising insulation or performance.

A. When selecting clean room doors, consider factors such as door thickness, insulation level, fire and safety compliance, and industry-specific standards. Working with an experienced clean room door manufacturer ensures you get the right solution for your environment.

A. No, our clean room doors are long-lasting and low maintenance. Made with durable PUF panels and hygienic finishes, each cleanroom door is easy to clean and designed to withstand heavy use without compromising performance.

Conclusion

In industries where precision, hygiene, and compliance are essential, investing in the right clean room doors is not optional—it is a necessity. With PUF panel technology, Technopuff Solutions delivers advanced clean room doors that combine airtight sealing, high insulation, and hygienic finishes to create environments that are both sterile and efficient. From pharmaceutical manufacturing to biotech research, food processing, healthcare, and electronics, our solutions are trusted across sectors for their durability and performance.

As a reliable clean room door manufacturer, we understand that every facility has unique requirements. That is why our expertise in clean room door design allows us to create customized solutions tailored to meet specific industry standards such as GMP, ISO, and FDA. Whether you need a highly specialized pharmaceutical clean room door for sterile drug production or modular clean room doors for advanced laboratories, our products are designed to exceed expectations.

Choosing Technopuff Solutions means choosing long-lasting quality, compliance, and innovation. Our commitment to excellence ensures that your clean room remains a safe, controlled, and contamination-free environment at all times. For more information regarding doors and PUF Panels, you can go to our Homepage.