Understanding Cold Storage Prices

In today’s rapidly advancing world, the role of cold storage is paramount across various industries, prominently within agriculture and the broader food supply chain. Cold storage facilities are essential for maintaining the quality and longevity of perishable goods, ranging from cold storage for vegetables, fruits, dairy, and seafood to pharmaceuticals, ensuring they reach consumers in optimal condition.

The arrival of Polyurethane Foam (PUF) panels has revolutionized the construction of these storage units. PUF panels for cold storage are not just an addition; they are a critical enhancement that bolsters the energy efficiency and effectiveness of these facilities. By improving insulation and reducing energy costs, PUF panels extend the viability of perishables and significantly diminish the cold storage cost, making the technology a game-changer in the logistics of perishables.

This blog aims to delve deep into the intricacies of cold storage prices and the cost of setting up cold storage facilities. With a focus on the unique benefits of PUF panels for cold storage, we will explore various types of cold storage solutions, factors influencing their costs, and how quality PUF panels impact the overall efficiency and price dynamics of building and maintaining cold storage units. Whether considering the mini cold storage price for smaller operations or the cold storage panels price for larger facilities, understanding these elements is essential for anyone looking to invest in or manage cold storage capabilities.

In summary, the utilization of advanced PUF Panels for cold storage solutions not only fosters better control of operational budgets but also enhances the sustainable management of resources, crucial for meeting the demands of a growing population and its increasing needs.

What is Cold Storage?

Cold storage is a critical infrastructure designed to store perishable goods under controlled temperatures to extend their shelf life and maintain quality. This technology is essential in numerous sectors, especially in agriculture, where it plays an important role in managing the supply chain of perishables like cold storage for vegetables, fruits, meats, and dairy products. By regulating the storage temperature, cold storage helps in stabilizing cold storage prices and reducing waste, making it an integral part of food security and distribution networks.

Types of Cold Storage

The versatility of cold storage solutions caters to a broad range of industry needs, each tailored to specific types of goods:

- Bulk Cold Storage : These are large-scale facilities designed to store goods in massive quantities, typically used by producers and wholesalers for storing large batches of a single type of product.

- Mini Cold Storage : Smaller in scale, these facilities are suited for small businesses or locations with limited space. The mini cold storage price is significantly lower, making it an accessible option for small to medium enterprises.

- Multipurpose Cold Storage : These units are flexible in terms of the range of products they can store, accommodating varying requirements at different times of the year.

- Specialized Cold Storages : Designed for specific products, these storages might have unique temperature and humidity controls. For example, storages for dairy products and seafood each require different settings to ensure freshness and prevent spoilage.

The Role of PUF Panels in Cold Storage

PUF panels for cold storage stand out as a superior construction material due to their excellent insulation properties. These panels significantly reduce the cold storage cost by minimizing the energy required to maintain optimal temperatures. The integration of PUF panels is pivotal in the design of both large and mini cold storage setups, where maintaining energy efficiency with cost-effectiveness is crucial.

Benefits of PUF Panels for Cold Storage

The use of PUF panels in constructing cold storage units offers numerous benefits:

- Insulation Excellence : PUF panels provide high thermal resistance, which reduces thermal bridging and heat gain.

- Energy Efficiency : The airtight seal and thermal resistance of PUF panels decrease the amount of energy needed for refrigeration.

- Cost Savings: With enhanced energy efficiency, the operational costs drop significantly, which is crucial in managing the cold storage panels price and overall cost of setting up cold storage.

- Durability: PUF panels are known for their strength and longevity, which is essential to maintain the integrity of cold storage facilities over time.

The use of PUF panels not only impacts the cold storage PUF panel price but also plays a critical role in enhancing the functionality and economic viability of cold storage facilities. By choosing the right type of cold storage and incorporating advanced materials like PUF panels, businesses can achieve greater control over their perishables, leading to better market prices and reduced wastage.

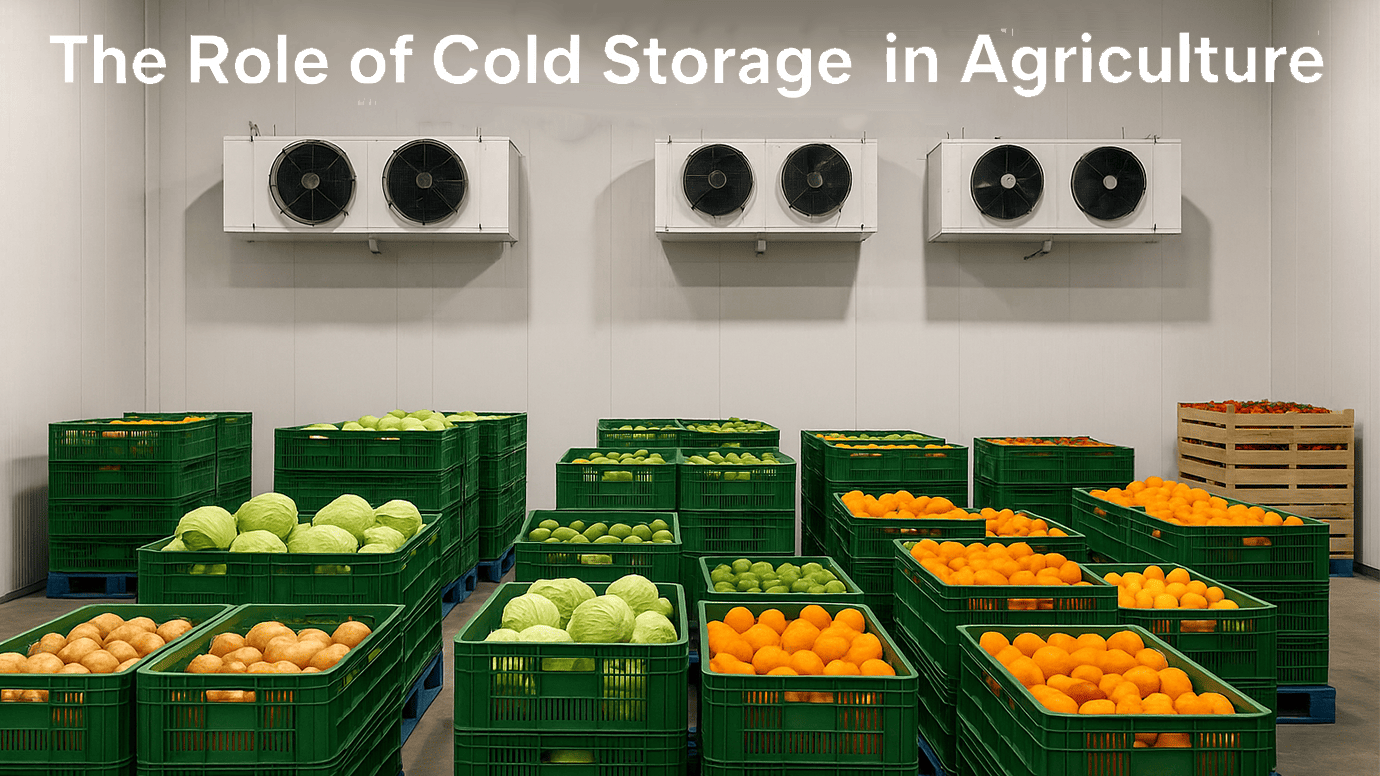

The Role of Cold Storage in Agriculture

In Indian agriculture, cold storage is crucial for the preservation and longevity of perishable agricultural products such as fruits and vegetables. This importance extends to managing cold storage prices, enhancing food quality, and ensuring consistent market supply.

Importance of Cold Storage in Agriculture

Cold storage facilities are indispensable in Indian agriculture. A significant part of India's economy depends on agriculture, where cold storage plays a pivotal role in preventing post-harvest losses. Proper cold storage solutions are critical for maintaining the freshness of agricultural produce from harvest through to market, thus enhancing the cold storage prices by reducing supply fluctuations.

Impact on Food Wastage and Supply Chain

Cold storage units significantly impact food wastage reduction. By maintaining optimal conditions, cold storage ensures that perishables, particularly cold storage for vegetables and fruits, endure through the supply chain with minimal spoilage. This reduction in wastage is crucial for stabilizing cold storage prices and improving the efficiency of the agricultural supply chain, especially in a country like India where the supply chain is often disrupted by logistical and climatic challenges.

Contribution of PUF Panels in Agriculture

PUF panels for cold storage are essential in enhancing the functionality and efficiency of cold storage facilities. These panels are key to maintaining necessary low temperatures consistently, which is vital for the longevity of perishable goods.

- Maintaining Required Temperatures : The superior insulation properties of PUF panels help in keeping the cold storage cost low by maintaining the required temperatures effectively, which is crucial for temperature-sensitive commodities.

- Reducing Spoilage: The effective temperature control provided by PUF panels minimizes spoilage risks, thereby maintaining optimal quality and freshness of stored goods. This control is directly beneficial for regulating cold storage prices and reducing overall cold storage cost.

- Cost Efficiency: The energy efficiency of PUF panels lowers the amount of energy needed to operate cold storages efficiently, thus impacting the cold storage cost positively. Lower energy requirements not only reduce operational costs but also decrease the cost of setting up cold storage, affecting both cold storage panels price and cold storage PUF panel price.

The integration of PUF panels for cold storage in agricultural storage facilities significantly enhances their operational efficiency and economic viability. For the agriculture sector in India, this advancement means better food preservation, decreased wastage, and more stable cold storage prices. Ultimately, using high-performance materials like PUF panels in constructing cold storage units is a wise investment in the sustainable future of agriculture, which reflects in more stable mini cold storage price and market rates.

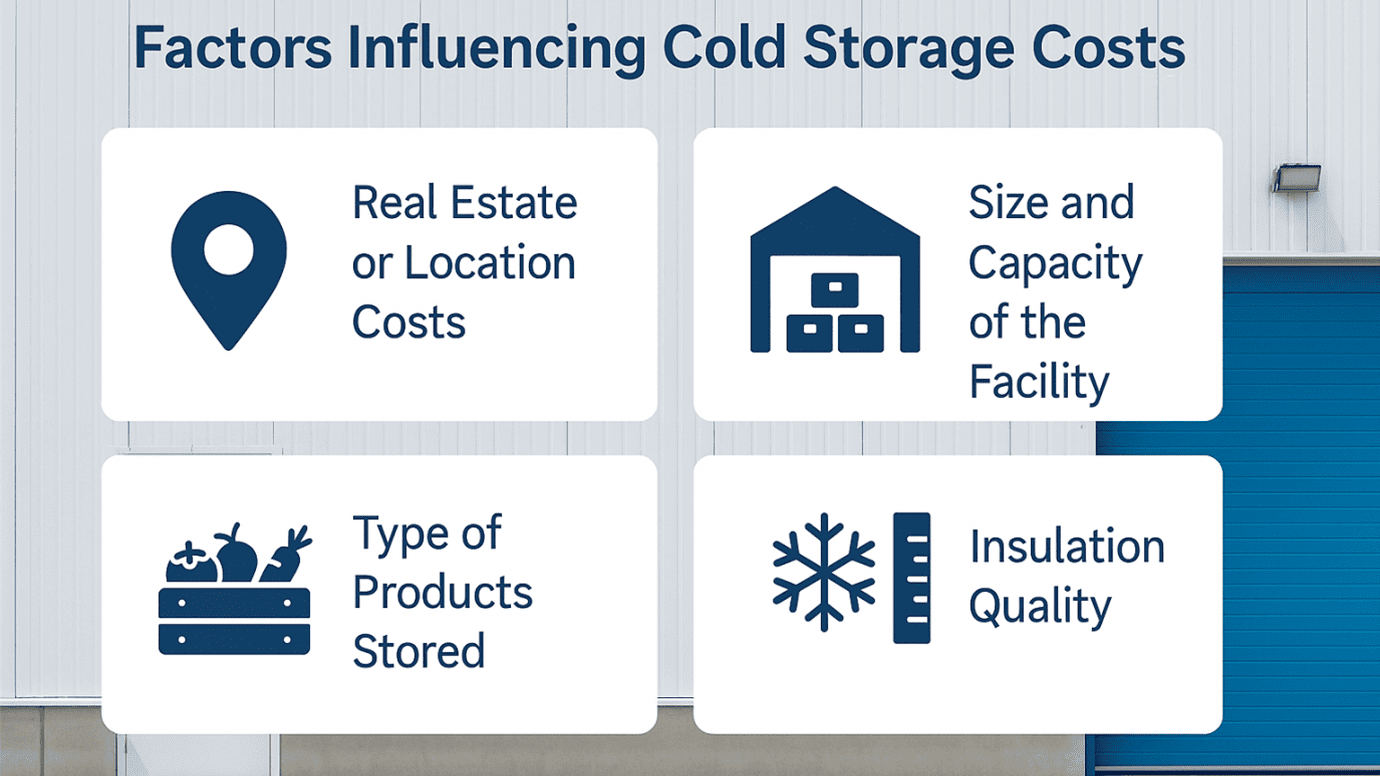

Factors Influencing Cold Storage Costs

Understanding the cold storage cost involves analyzing various factors that influence how these facilities operate and the expenses involved. These factors play an important role in determining overall cold storage prices and can vary significantly across different regions of India.

Real Estate or Location Costs

The location of a cold storage facility significantly affects the cold storage cost. Prime locations with better accessibility to major markets and transport links tend to have higher land and construction costs. However, the benefits of reduced transportation times and lower risk of product spoilage can justify the higher initial investment. In contrast, facilities in more remote areas might reduce initial land costs but increase transportation expenses and decrease the efficiency of distributing perishable products like cold storage for vegetables.

Size and Capacity of the Facility

The size and capacity of a cold storage facility directly impact the cold storage prices. Larger facilities benefit from economies of scale, potentially lowering the per unit storage cost. However, the initial cost of setting up cold storage of a larger scale is substantially higher. Facility size must be matched with demand to avoid underutilization, which can escalate operating costs unnecessarily.

Type of Products Stored

Different products have varying storage requirements which influence cold storage prices. For instance, storing pharmaceuticals or high-value electronics in cold storage demands precise temperature controls and higher security, increasing costs. In contrast, cold storage for vegetables may not require as stringent temperature settings but might need larger spaces due to volume, affecting the cold storage cost differently.

Impact of Insulation Quality

The quality of insulation is critical in determining the efficiency and operating costs of cold storages. PUF panels for cold storage are known for their superior insulation properties, which can greatly reduce energy consumption and, consequently, the overall cold storage cost. High-quality PUF panels ensure better temperature management and reduce the risk of fluctuations that could lead to spoilage, thus maintaining optimal cold storage prices.

Comparison of Cold Storage Costs in Different Regions of India

The cost of setting up cold storage can vary widely across different regions of India due to variations in climate, land costs, labor rates, and local regulations. For instance, the cold storage cost in densely populated urban centers like Mumbai and Delhi is higher compared to rural areas. However, urban settings often result in higher turnover rates and potentially lower cold storage prices due to higher demand. In contrast, rural areas might offer lower setup costs but could incur higher operational costs due to issues like less reliable electricity supply and logistical challenges.

Understanding these factors is crucial for anyone involved in the planning, construction, or operation of cold storage facilities. By considering the specific needs based on location, size, product type, and insulation quality, stakeholders can effectively manage and optimize cold storage costs, ensuring a balance between efficiency and operational sustainability. This balance is vital for maintaining competitive cold storage prices and cold storage panels price, particularly when considering the investment in PUF panels for cold storage and the variability in cold storage PUF panel price across different markets.

Cold Storage Price List

When planning to set up or expand cold storage facilities, one of the primary considerations is the cold storage price list. This price list varies widely based on several factors including the type of cold storage, the technology used, the location, and the quality of construction materials such as PUF panels. Below is a chart of various cold storage types, the suitable thickness of PUF panels for each, and an estimated price range.

Cold Storage Type

PUF Panel Thickness (mm)

Estimated Price Range (INR per sq. ft.)

Cold Storage Type | PUF Panel Thickness (mm) | Estimated Price Range (INR per sq. ft.) |

Multipurpose Cold Storage (Fruits & Vegetables, Mushroom Farming chambers) | 60 – 100 | 1,270 – 1,690 |

Specialized Cold Storage | ||

– Dairy/ Ice-cream | 100 – 150 | 1,690 – 2,220 |

– Seafood | 120 – 200 | 1,900 – 2,740 |

– Pharmaceuticals | 150 – 200 | 2,220 – 2,740 |

Mini Cold Storage (Flowers & for small farmers) | 50 – 80 | 1,170- 1,480 |

Note: The above prices are for PUF Panels with 0.4mm PPGI sheet both side. There would be customization options in sheet thickness.

The prices listed above are rough estimates and does not include GST, Transportation and other miscellaneous charges. Stakeholders are encouraged to consult with industry experts like Technopuff Solutions to get precise figures tailored to their specific needs and location within India.

Future Trends and Innovations in Cold Storage

As the demand for efficient and sustainable cold storage solutions continues to rise in India, staying abreast of industry trends and technological advancements is essential. This section explores the evolving role of PUF panels and other emerging trends and innovations that are shaping the future of the cold storage industry. These developments not only aim to enhance operational efficiencies but also strive to keep the cold storage prices competitive.

The Evolving Role of PUF Panels

PUF panels for cold storage are increasingly recognized for their superior insulation properties, which significantly reduce energy consumption and, consequently, the cold storage cost. As the market evolves, the technology behind PUF panels continues to advance, leading to even more efficient designs that promise better thermal resistance and durability.

- Enhanced Thermal Efficiency : Future advancements are expected to focus on increasing the thermal resistance of PUF panels without increasing their thickness, promoting space efficiency in cold storage facilities.

- Eco-Friendly Materials : Research is also geared towards making PUF panels more environmentally friendly by using sustainable raw materials that contribute less to environmental degradation while maintaining their insulative properties.

Emerging Trends in the Cold Storage Industry

- Automation and Robotics : Automation technology in cold storage facilities is set to transform the landscape of inventory management and operations. Robotics can help reduce labor costs and minimize human error, making the storage and retrieval process more efficient and helping to stabilize cold storage prices.

- Internet of Things (IoT) Integration: IoT technology is becoming integral in monitoring and managing the internal conditions of cold storages remotely. Sensors can track temperature, humidity, and even product spoilage, which assists in maintaining optimal conditions and reducing the overall cold storage cost.

- Energy Management Systems: Advanced energy management systems that utilize AI to predict and adjust the energy needs of cold storage facilities can lead to substantial cost savings, directly affecting the cold storage panels price and overall operational expenses.

Technological and Material Advancements with a Focus on PUF Panel Improvements

- Smart PUF Panels: Future PUF panels might include integrated sensors that can provide real-time data on their performance and the internal environment of the cold storage unit. This technology can help predict maintenance needs and optimize energy use, potentially lowering the cold storage PUF panel price over time.

- Modular and Flexible Designs: The development of modular PUF panels that can be easily assembled and disassembled will allow for more flexible cold storage solutions. This adaptability can be particularly beneficial for small-scale operations, impacting the mini cold storage price and accessibility.

- Fire Resistance: Enhancing the fire-resistant properties of PUF panels is another area of focus, aiming to improve safety standards in cold storage facilities, thereby reducing insurance and risk-related costs.

The future of cold storage in India looks promising with continuous innovations in technology and materials, particularly in PUF panels. As these advancements are implemented, they are expected to drive down the cost of setting up cold storage, improve operational efficiencies, and expand the potential uses of cold storage facilities across various industries. Keeping an eye on these trends will help stakeholders make informed decisions that align with future market demands and regulatory standards, ensuring economic viability and environmental sustainability.

FAQs

A. Cold storage prices are primarily influenced by location, size and capacity of the facility, types of products stored, and the quality of insulation, particularly the use of PUF panels which can significantly impact energy efficiency and operational costs.

A. PUF panels provide superior insulation, which helps maintain desired temperatures with less energy consumption. This efficiency reduces energy costs, which is one of the main components of ongoing cold storage operational expenses.

A. The cost of setting up cold storage can vary widely depending on factors such as the location, size of the facility, and the type of insulation used. Using high-quality PUF panels, although initially more expensive, can lead to long-term savings due to lower energy costs.

A. Yes, there are specialized cold storages for vegetables that require maintaining specific humidity and temperature levels to prolong freshness and reduce spoilage. These facilities often utilize PUF panels to effectively control the internal climate.

A. Larger cold storage facilities generally benefit from economies of scale, potentially lowering the price per stored unit. However, larger facilities also mean higher initial investment in terms of both construction and operational setup.

A. Yes, mini cold storages are cost-effective solutions for small businesses as they require less capital investment and can be tailored to meet smaller operational demands while still providing efficient temperature control, especially when equipped with PUF panels.

A. Emerging trends include the integration of automation and robotics, IoT for real-time monitoring and management, and the use of advanced energy management systems. These technologies aim to reduce costs and increase the efficiency of cold storage operations.

A. It is crucial to consider the specific thermal requirements of the stored products and the local climate conditions. Technopuff Solutions provide appropriate PUF panels for your cold storage facility.

Conclusion

Throughout this blog, we’ve thoroughly examined the critical aspects of the cold storage industry in India, shedding light on the various types of cold storage solutions, from bulk storage to specialized facilities tailored for products like dairy and seafood. Each type of storage plays a vital role in maintaining the integrity of perishable goods, influencing cold storage prices and ensuring the stability of supply chains across the agricultural and pharmaceutical sectors.

In our discussion, we emphasized the importance of understanding the factors that impact cold storage costs, including the location, size, and specific storage requirements dictated by different products. One of the key elements we’ve explored is the significant role that insulation plays in the efficiency and cost-effectiveness of these facilities, particularly the use of PUF panels. These panels are crucial in managing energy consumption, which in turn affects the overall operational costs and sustainability of cold storage operations.

As the industry continues to evolve, we’ve also touched on the latest innovations and trends such as automation, IoT in cold storage management, and advancements in PUF panel technology. These developments are set to revolutionize the market, making cold storage operations more efficient and reducing cold storage prices over time.

For stakeholders looking to launch or enhance their cold storage facilities, the choice of construction materials and expert guidance is paramount. PUF panels for cold storage, offered by Technopuff Solutions, stand out for their superior quality and energy efficiency. These panels not only help in maintaining optimal storage conditions but also play a significant role in the long-term reduction of cold storage costs.

If you are planning to start your own cold storage project or are looking to optimize an existing facility, reaching out to Technopuff Solutions can provide you with access to top-tier PUF panels and expert advice tailored to your specific needs. Whether you are concerned about the mini cold storage price for smaller setups or need solutions for larger operations, Technopuff Solutions can assist you in navigating the complexities of cold storage costs and technology choices.

In summary, as the cold storage sector advances, incorporating high-quality materials like PUF panels and staying informed about pricing dynamics are essential strategies for building efficient and economically viable cold storage facilities. Connect with Technopuff Solutions today to ensure your cold storage project is equipped with the best materials and insights the industry has to offer.

For more information, go to our Support page for Cold Storage.