Laboratory Doors

In the world of scientific research, pharmaceuticals, and biotechnology, precision and control are everything. Every detail of a laboratory’s infrastructure—from its HVAC system to its flooring—contributes to maintaining the integrity of experiments and the safety of personnel. One often overlooked yet vital component of this ecosystem is the laboratory door. Far beyond being a simple entryway, a lab door is an integral part of a controlled environment, ensuring that external contaminants, fluctuating temperatures, and unwanted particles do not compromise sensitive processes.

The importance of a laboratory door lies in its ability to combine physical security with environmental control. Unlike conventional doors, lab doors are purpose-built to support cleanrooms, sterile zones, and research facilities where even the slightest contamination could lead to inaccurate results, product spoilage, or compromised safety. By acting as a shield, these specialized doors play a key role in maintaining air pressure differentials, reducing energy loss, and sustaining the hygienic conditions demanded by modern laboratories.

In industries such as pharmaceuticals, food processing, biotechnology, and healthcare, the demand for advanced lab doors is higher than ever. Laboratories in these sectors require more than just durability—they need doors that are hygienic, thermally insulated, resistant to chemicals, and easy to clean. This is where PUF panel laboratory doors stand apart from traditional alternatives.

PUF (Polyurethane Foam) panel technology has revolutionized laboratory infrastructure by offering exceptional insulation, lightweight strength, and long-lasting durability. A laboratory door made from PUF panels is not only energy-efficient but also designed to meet the stringent hygiene standards required in research and production environments. Their seamless finish, airtight sealing, and superior thermal performance make them the modern choice for facilities that cannot afford compromise.

In short, choosing the right laboratory door is not just about convenience; it’s about protecting people, products, and processes. And with lab doors made from advanced PUF panels, laboratories gain a trusted partner in creating safe, hygienic, and future-ready environments.

What Are Laboratory Doors?

A laboratory door is more than just an entry or exit point—it is a specialized barrier designed to maintain hygiene, safety, and controlled conditions inside critical environments. Unlike ordinary doors used in residential or commercial buildings, lab doors are engineered to meet the strict requirements of pharmaceutical companies, biotechnology firms, food processing units, and research facilities. They play a vital role in ensuring that laboratories remain free from dust, microbes, and other external contaminants while also supporting internal air pressure and temperature control.

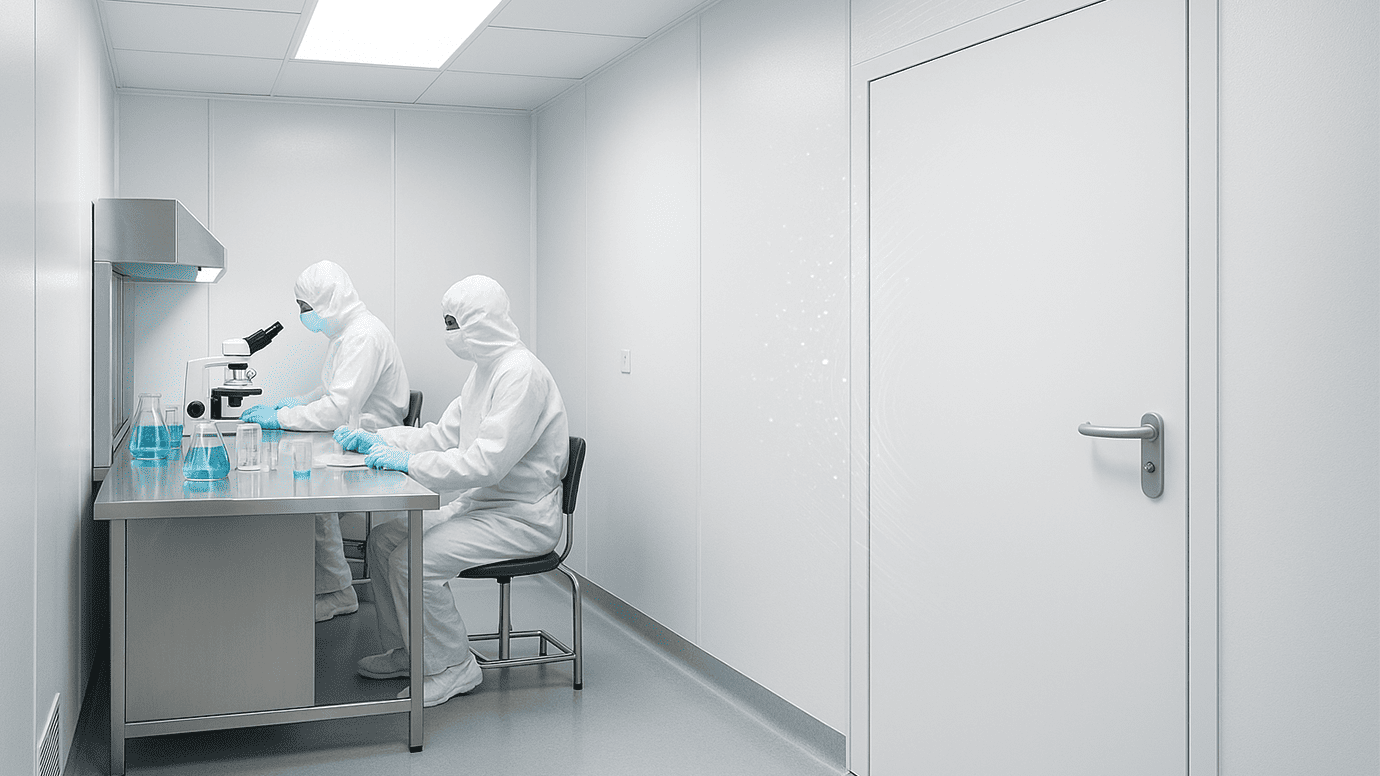

At the core of modern laboratory door design is the use of PUF (Polyurethane Foam) panels. These panels are known for their outstanding insulation properties, durability, and lightweight strength. PUF panels consist of a rigid foam core sandwiched between two protective metal sheets, usually made of pre-coated galvanized steel or stainless steel. This construction provides excellent thermal insulation, helping laboratories reduce energy consumption and maintain consistent internal conditions.

When used in the manufacturing of lab doors, PUF panels deliver unmatched performance. They create doors that are airtight, chemically resistant, and easy to clean—qualities that are essential in laboratories where sterility and precision are top priorities. The insulating properties of PUF panels also prevent unwanted heat transfer, ensuring that temperature-sensitive processes and equipment remain unaffected by external fluctuations.

A PUF panel laboratory door combines functionality with durability. It not only resists wear and tear from frequent use but also offers superior protection against microbial growth due to its smooth, non-porous surface. Additionally, these lab doors can be customized in terms of size, thickness, and hardware to suit the specific needs of different laboratory environments, whether it’s a pharmaceutical cleanroom, a chemical testing area, or a biotechnology research lab.

In essence, a laboratory door made from PUF panels is the perfect fusion of advanced engineering and practical design. It ensures safety, improves energy efficiency, and provides long-term reliability—making it the modern standard for laboratories that demand uncompromised performance.

Key Features of PUF Panel Laboratory Doors

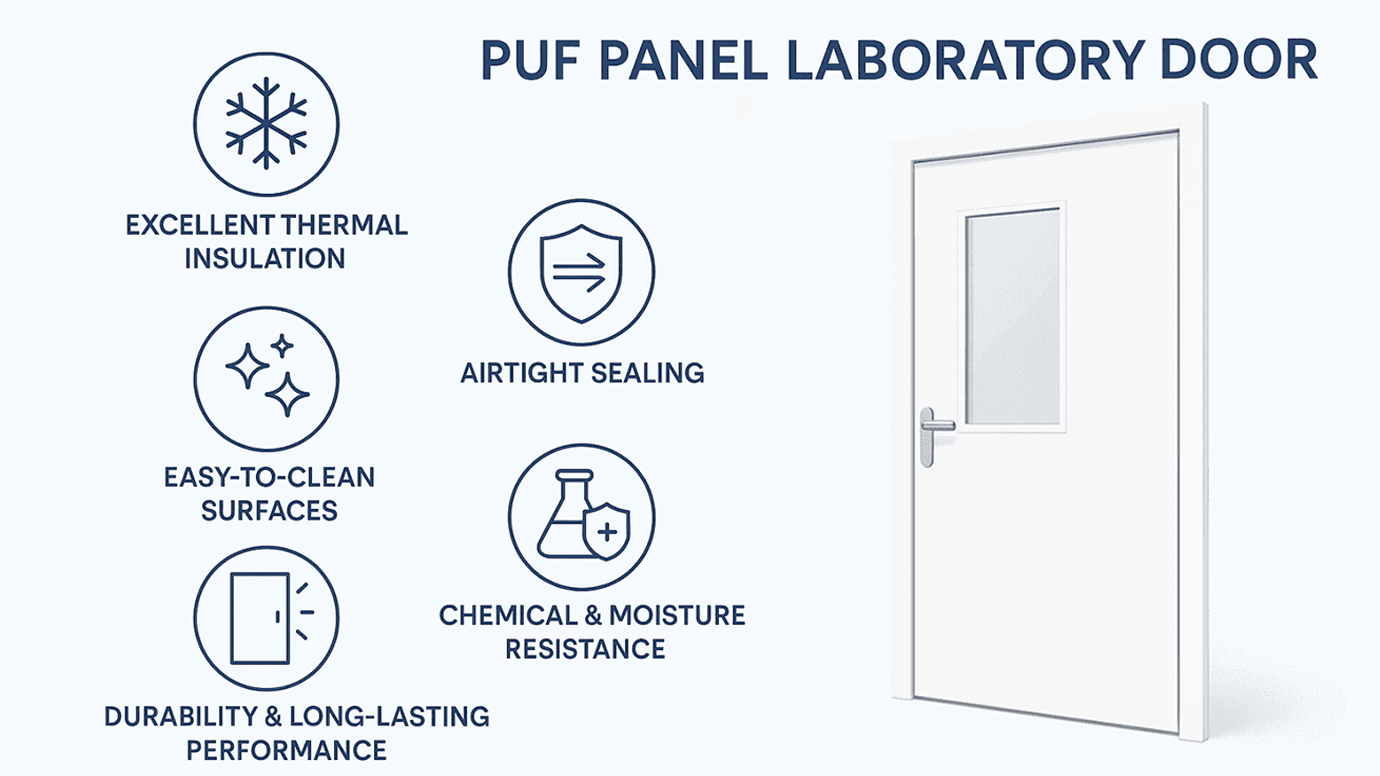

A laboratory door is not just a physical barrier—it is an essential component that ensures the integrity of controlled environments. When manufactured with advanced PUF (Polyurethane Foam) panels, lab doors deliver a range of features that make them indispensable in modern laboratories. Below are the standout features that set these doors apart:

Excellent Thermal Insulation

One of the greatest strengths of a PUF panel laboratory door is its superior thermal insulation. The rigid foam core acts as a barrier against heat transfer, helping laboratories maintain stable internal temperatures. This is especially important in cleanrooms, cold storage areas, and research facilities where even minor fluctuations can disrupt experiments or damage sensitive materials. By minimizing energy loss, these lab doors also contribute to reduced electricity costs and improved energy efficiency.

Air-Tight Sealing to Prevent Contamination

In a laboratory, preventing contamination is a top priority. A well-designed laboratory door with PUF panels ensures airtight sealing that blocks the entry of dust, microbes, and pollutants. This airtightness helps maintain pressure differentials between different lab zones, a crucial requirement for cleanroom environments. With such sealing, lab doors provide a reliable defense against contamination, safeguarding research quality and product safety.

Smooth, Easy-to-Clean Surfaces

Hygiene and cleanliness are non-negotiable in labs. PUF panel-based laboratory doors are designed with smooth, non-porous surfaces that are simple to clean and disinfect. The absence of joints or cracks prevents the accumulation of dust or microbial growth, making these lab doors ideal for pharmaceutical and biotechnology environments where sterilization is mandatory.

Resistance to Chemicals and Moisture

Laboratories often use chemicals, solvents, and sterilizing agents that can damage conventional doors. A PUF panel laboratory door is resistant to both chemicals and moisture, ensuring long-term reliability even in harsh working conditions. This chemical resistance makes lab doors suitable for testing labs, food processing facilities, and cleanrooms where frequent cleaning and chemical exposure are unavoidable.

Durable, Long-Lasting Performance

Durability is another defining feature of a laboratory door made from PUF panels. These doors are engineered to withstand heavy usage without warping, corroding, or losing their insulating properties. Their robust structure ensures long-lasting performance, reducing the need for frequent repairs or replacements. For facilities that operate 24/7, investing in durable lab doors translates into lower maintenance costs and uninterrupted operations.

The key features of PUF panel-based laboratory doors—thermal insulation, airtight sealing, easy maintenance, chemical resistance, and durability—make them a trusted choice for industries that prioritize hygiene and efficiency. By choosing high-quality lab doors, laboratories can create safer, more energy-efficient, and contamination-free environments that fully support their critical operations.

Benefits of Using PUF Panel Laboratory Doors

Choosing the right laboratory door is an investment in both safety and efficiency. When constructed with PUF (Polyurethane Foam) panels, lab doors offer unmatched advantages that go far beyond basic functionality. These benefits make them the preferred choice for industries such as pharmaceuticals, biotechnology, healthcare, and food testing.

Energy Efficiency: Reduced Power Consumption for Controlled Environments

A well-designed PUF panel laboratory door plays a vital role in reducing energy consumption. The high-density foam core acts as an effective insulator, preventing heat transfer between laboratory zones and external areas. This minimizes the workload on HVAC systems, helping facilities maintain strict temperature and humidity levels with less energy. By installing these lab doors, laboratories not only protect sensitive experiments but also achieve significant savings on electricity bills.

Hygiene & Safety: Maintaining Sterile Conditions

Maintaining sterility is crucial in environments where contamination can compromise results or product quality. A laboratory door with PUF panels provides airtight sealing, ensuring no dust, microbes, or airborne particles enter controlled spaces. The smooth, non-porous surface of these lab doors is also resistant to bacterial growth and can be easily sanitized, making them ideal for cleanrooms and research facilities. This focus on hygiene and safety ensures compliance with industry standards while protecting personnel and equipment.

Cost-Effectiveness: Long-Term Savings Due to Durability

While the initial investment in a PUF panel laboratory door may be higher than standard options, the long-term benefits are undeniable. These lab doors are built to withstand heavy usage, frequent cleaning, and chemical exposure without losing their structural integrity or insulation properties. Their durability reduces the need for repairs and replacements, resulting in substantial cost savings over the years. For laboratories operating round the clock, this cost-effectiveness becomes a critical advantage.

Customized Cold Room Doors

Every laboratory has unique requirements depending on its operations, layout, and safety standards. A major advantage of PUF panel-based laboratory doors is the wide scope for customization. From door sizes and panel thicknesses to hardware, finishes, and locking systems, these lab doors can be tailored to meet exact specifications. Whether it’s a pharmaceutical cleanroom needing hermetic sealing or a food testing lab requiring high chemical resistance, customization ensures that every facility gets the perfect fit.

The benefits of choosing PUF panel-based laboratory doors—energy efficiency, superior hygiene, cost-effectiveness, and customization—make them the ideal solution for modern labs. By investing in high-quality lab doors, facilities not only enhance safety and compliance but also enjoy long-term operational efficiency and financial savings.

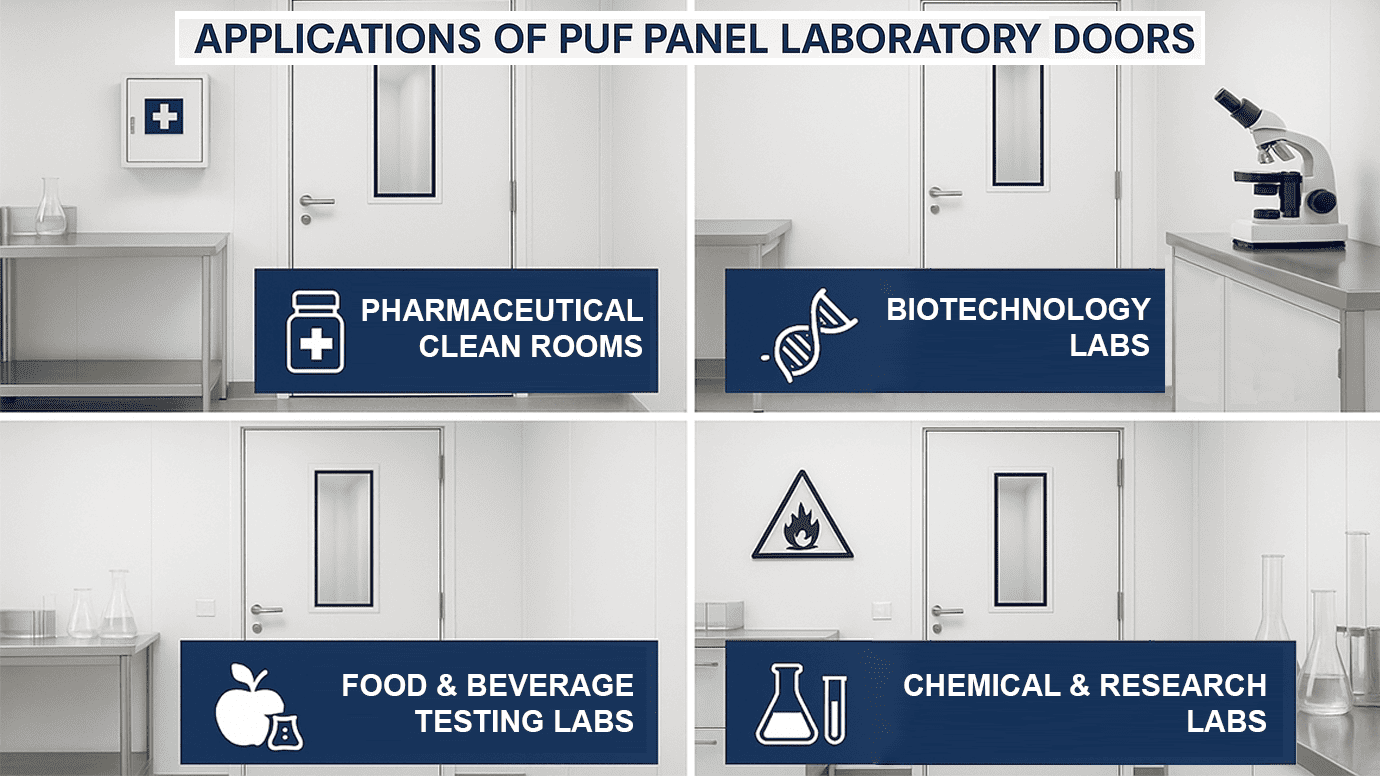

Applications of Laboratory Doors

A laboratory door is not just an architectural element—it is a critical component that directly impacts the functionality, safety, and compliance of specialized facilities. Built with PUF (Polyurethane Foam) panels, modern lab doors are designed to meet the demanding requirements of industries where precision and hygiene are non-negotiable. Their versatility makes them suitable for a wide range of applications across sectors such as pharmaceuticals, biotechnology, food, and chemical research.

Pharmaceutical Clean Rooms

In pharmaceutical facilities, maintaining sterile and contamination-free environments is essential. A laboratory door designed for cleanrooms ensures airtight sealing, preventing the entry of dust, microbes, and airborne contaminants. PUF panel-based lab doors also support controlled temperature and pressure conditions, making them indispensable for drug formulation, packaging, and quality testing areas. Their smooth, easy-to-clean surfaces further enhance compliance with Good Manufacturing Practices (GMP).

Biotechnology Labs

Biotechnology laboratories require an environment where precision and sterility are paramount. A PUF panel laboratory door provides insulation, chemical resistance, and hygiene, ensuring that sensitive research processes remain unaffected by external disturbances. These lab doors play a key role in maintaining biosafety levels, helping laboratories handle genetic, microbial, and molecular experiments with confidence.

Food & Beverage Testing Labs

Food and beverage testing facilities must meet strict safety and hygiene standards to ensure consumer health. A laboratory door with PUF panel construction helps maintain contamination-free zones by offering airtight sealing and easy-to-sanitize surfaces. These lab doors prevent cross-contamination during quality checks, microbiological testing, and product validation, safeguarding both research integrity and regulatory compliance.

Chemical & Research Labs

Chemical and multidisciplinary research labs often deal with volatile substances and sensitive experiments. A laboratory door made with PUF panels is resistant to chemicals, moisture, and frequent cleaning agents, ensuring durability in demanding environments. By maintaining thermal stability and airtight conditions, these lab doors help create safe and controlled spaces for high-precision research, testing, and development activities.

From pharmaceutical cleanrooms to chemical research facilities, the applications of PUF panel-based laboratory doors are vast and diverse. Their ability to deliver hygiene, durability, and energy efficiency makes lab doors an essential feature in any controlled environment where safety and performance cannot be compromised.

Why Choose Technopuff Solutions for Laboratory Doors?

Selecting the right laboratory door is a decision that goes beyond functionality—it is about ensuring safety, hygiene, and efficiency for critical environments. With years of expertise and a proven track record, Technopuff Solutions has emerged as a trusted name in the industry for delivering high-performance lab doors made from premium PUF panels. Here’s why partnering with us makes all the difference:

Expertise in PUF Panel Manufacturing

At Technopuff Solutions, we specialize in designing and manufacturing products built from advanced PUF (Polyurethane Foam) panels. This expertise allows us to craft every laboratory door with precision, ensuring superior insulation, airtightness, and durability. Our in-depth knowledge of PUF technology ensures that our lab doors not only meet but exceed the expectations of pharmaceutical, biotechnology, and research facilities.

Focus on Quality, Innovation, and Compliance

We understand that laboratories demand infrastructure that complies with strict industry standards. Every PUF panel laboratory door we manufacture undergoes rigorous quality checks to guarantee performance, hygiene, and safety. Our commitment to innovation ensures that we continuously improve our designs, offering modern, easy-to-clean surfaces, seamless finishes, and chemical resistance. These features make our lab doors ideal for cleanrooms and specialized environments where even the smallest compromise is unacceptable.

Competitive Pricing and Timely Delivery

Technopuff Solutions stands out for offering high-quality laboratory doors at competitive prices. We believe that world-class solutions should be accessible without exceeding budgets. Along with affordability, we pride ourselves on our commitment to timely delivery. Whether it’s a single project or a large-scale installation, our lab doors are manufactured and delivered on schedule, helping clients maintain their project timelines without disruption.

With a combination of technical expertise, a focus on uncompromised quality, and customer-centric service, Technopuff Solutions is the preferred choice for PUF panel-based laboratory doors. Our lab doors embody durability, hygiene, and efficiency, ensuring that your laboratory infrastructure is equipped to meet the highest standards of performance and compliance.

FAQs

A. A laboratory door is specifically designed for controlled environments such as cleanrooms and research facilities. Unlike regular doors, lab doors offer airtight sealing, superior insulation, and hygienic surfaces to maintain sterility and safety.

A. PUF panel-based laboratory doors provide excellent thermal insulation, durability, and chemical resistance. These lab doors also help maintain contamination-free environments, making them ideal for pharmaceutical and biotechnology laboratories.

A. A laboratory door built with PUF panels has smooth, non-porous surfaces that are easy to clean and disinfect. Such lab doors prevent microbial growth and ensure that cleanrooms maintain the highest hygiene standards. For more detailed information, you can also read our dedicated blog on Clean Room Doors.

A.A laboratory door constructed with PUF panels is highly durable and long-lasting. These lab doors can withstand frequent use, heavy cleaning, and challenging lab conditions without losing performance.

A.Technopuff Solutions has proven expertise in manufacturing PUF panel lab doors that meet global quality and compliance standards. Each laboratory door is crafted with a focus on durability, hygiene, energy efficiency, and timely delivery, making us a trusted partner for laboratories across industries.

Conclusion

The choice of a laboratory door is far more than a construction decision—it is an investment in safety, hygiene, and operational excellence. In environments such as pharmaceutical cleanrooms, biotechnology research centers, food testing labs, and chemical facilities, the right lab doors help protect sensitive processes, maintain sterility, and ensure compliance with international standards. A well-designed laboratory door built with PUF panels not only delivers superior insulation and airtightness but also provides long-term durability and cost efficiency.

At Technopuff Solutions, we understand the critical role that lab doors play in modern laboratories. With our expertise in PUF panel manufacturing, commitment to quality, and focus on innovation, we deliver solutions that meet the highest performance benchmarks. Each laboratory door we manufacture is crafted to provide reliability, hygiene, and energy efficiency—qualities that are essential for today’s demanding research and production environments.

If you are looking for durable, customizable, and high-performance lab doors, Technopuff Solutions is your trusted partner. We combine technical excellence with customer-focused service to deliver products that truly enhance laboratory infrastructure.

Contact us today to discuss your specific laboratory door requirements and discover how Technopuff Solutions can provide the perfect solution for your facility. For more information regarding PUF Panels, doors and structures made from it, you can explore our Homepage.