PUF Panel Poultry Farm

In recent years, the demand for high-yield, sustainable poultry farming has grown exponentially. Whether it’s a large-scale chicken farm, a specialized egg farm, or a fully integrated broiler poultry farm, modern poultry operations face one key challenge: creating a controlled, hygienic, and thermally balanced environment for the birds. This is where insulated poultry houses and advanced building materials come into play.

A well-constructed poultry shed is no longer just a shelter—it is a vital component in maintaining bird health, ensuring consistent productivity, and maximizing profitability. With rising climate uncertainties and biosecurity threats, conventional building materials fall short in meeting the needs of the ideal poultry farm. Layer farming, and hen farm setups all require precise temperature control, disease prevention, and ease of sanitation to remain competitive and efficient.

Enter PUF panel technology—a game-changer in modern poultry farm construction. With their excellent thermal insulation, moisture resistance, and structural strength, PUF (Polyurethane Foam) panels are rapidly replacing traditional materials in chicken poultry farm setups. These panels are not only cost-effective but also significantly improve the overall environment within poultry houses, leading to healthier flocks and higher returns.

At the forefront of this transformation is Technopuff Solutions, a leading innovator in PUF panel manufacturing. With a commitment to quality, durability, & energy efficiency, Technopuff is revolutionizing the way poultry sheds are built. Their custom-designed PUF panels cater to the unique needs of every poultry farm, from compact egg farms to expansive broiler poultry farms, making them a trusted partner for sustainable farming success.

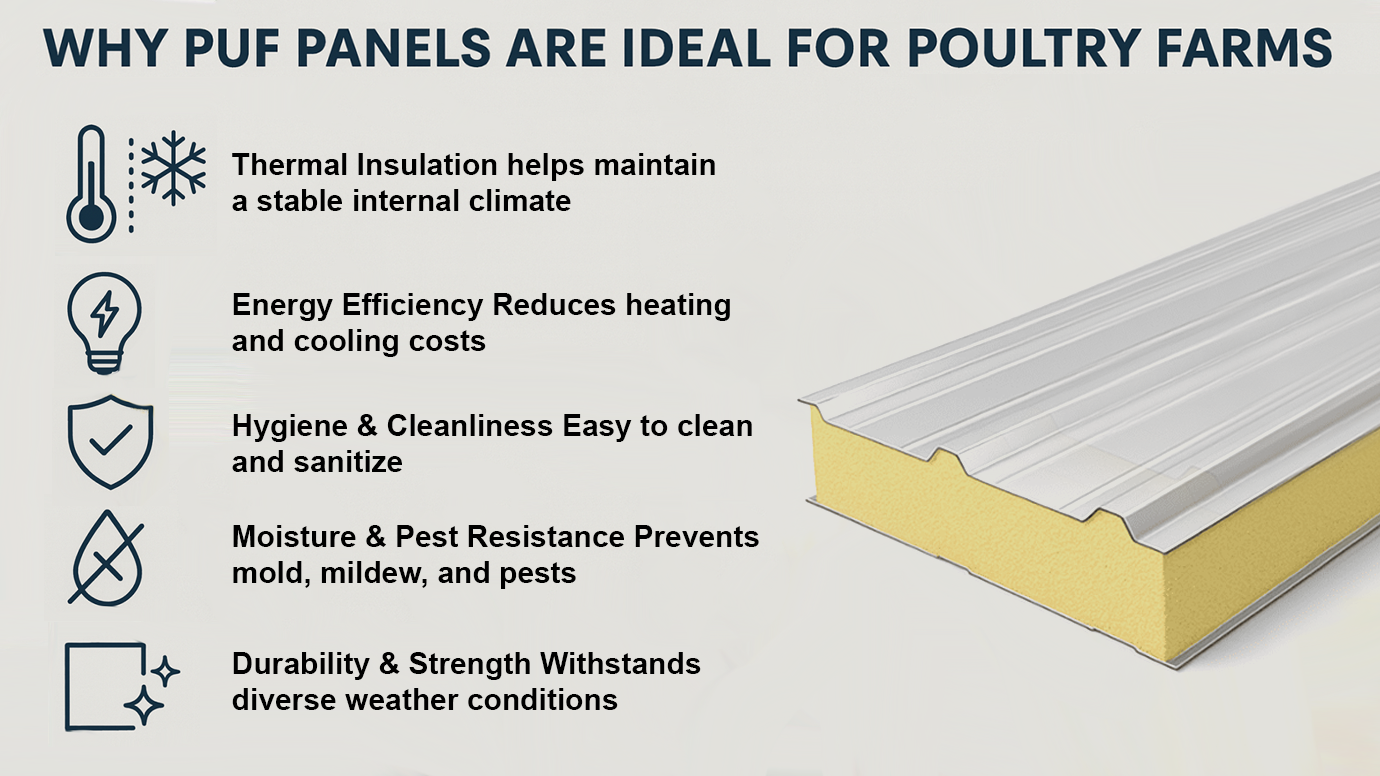

Why PUF Panels Are Ideal for Poultry Farms

As the demand for efficient, hygienic, and scalable poultry infrastructure grows, the PUF Panel Poultry Farm concept is fast becoming the gold standard in modern agriculture. Whether you’re running a small poultry farm, expanding a broiler poultry farm, or building a new poultry farm from the ground up, PUF panels offer unmatched advantages in creating a productive and sustainable farming environment.

Thermal Insulation:

Maintaining a stable internal climate is critical in any poultry farm, particularly in high-yield environments like a layer poultry farm or an egg farm. PUF panels are known for their exceptional thermal insulation properties, which help keep poultry houses cool in the summer & warm during colder months.

Inconsistent temperatures can lead to stress, increased feed consumption, and higher mortality rates. In contrast, well-insulated poultry sheds made with PUF panels create an ideal microclimate that supports bird comfort and growth. This is especially vital for temperature-sensitive operations such as chicken poultry farms and hen poultry farms, where climate control is directly linked to egg-laying or weight gain efficiency.

Energy Efficiency

A major advantage of using PUF panels in a poultry farm shed is the significant reduction in energy costs. Thanks to their high insulation value, the need for external heating or cooling systems is greatly minimized. This makes them particularly valuable for a poultry farm in remote locations with limited access to power.

For a modern poultry farm looking to reduce its carbon footprint and operational expenses, PUF Panel Poultry Farm construction is a wise investment. Lower utility bills combined with better flock performance result in higher profitability over time.

Hygiene & Cleanliness

Hygiene is a non-negotiable factor in every chicken farm or layer farming setup. The smooth, non-porous surfaces of PUF panels are easy to clean and sanitize. Unlike conventional materials that absorb moisture and harbor pathogens, PUF panels reduce the risk of contamination, helping maintain biosecurity standards.

Whether you're operating a new poultry farm or upgrading an existing modern poultry facility, having a structure that promotes cleanliness directly reduces disease outbreaks and boosts flock health.

Moisture & Pest Resistance

Humidity and poor ventilation are breeding grounds for mold, mildew, and pests in traditional poultry farm sheds. However, PUF Panel Poultry Farms are inherently resistant to moisture penetration, keeping internal surfaces dry and pest-free. This enhances the longevity of the shed and ensures a healthier environment for birds.

For farmers running egg hen farms, or broiler farms, pest resistance means lower risk of parasite infestations and a cleaner space for growth and production.

Durability & Strength

PUF panels are built to last. They can withstand diverse weather conditions—be it scorching sun, heavy rain, or strong winds—without warping or deteriorating. This durability makes them ideal for both large-scale modern poultry farms and compact small poultry farms.

The long lifespan and low maintenance needs of these structures translate into reduced replacement costs and consistent protection for your flock. Whether you're building an ideal poultry farm or a mini poultry farm, PUF panels provide a resilient backbone to your operations.

By integrating PUF panels into your poultry houses, you’re not just constructing a building—you’re creating a high-performance environment tailored to maximize bird welfare and farm efficiency. It’s no wonder that more farmers are shifting toward the PUF Panel Poultry Farm model as the cornerstone of sustainable poultry success.

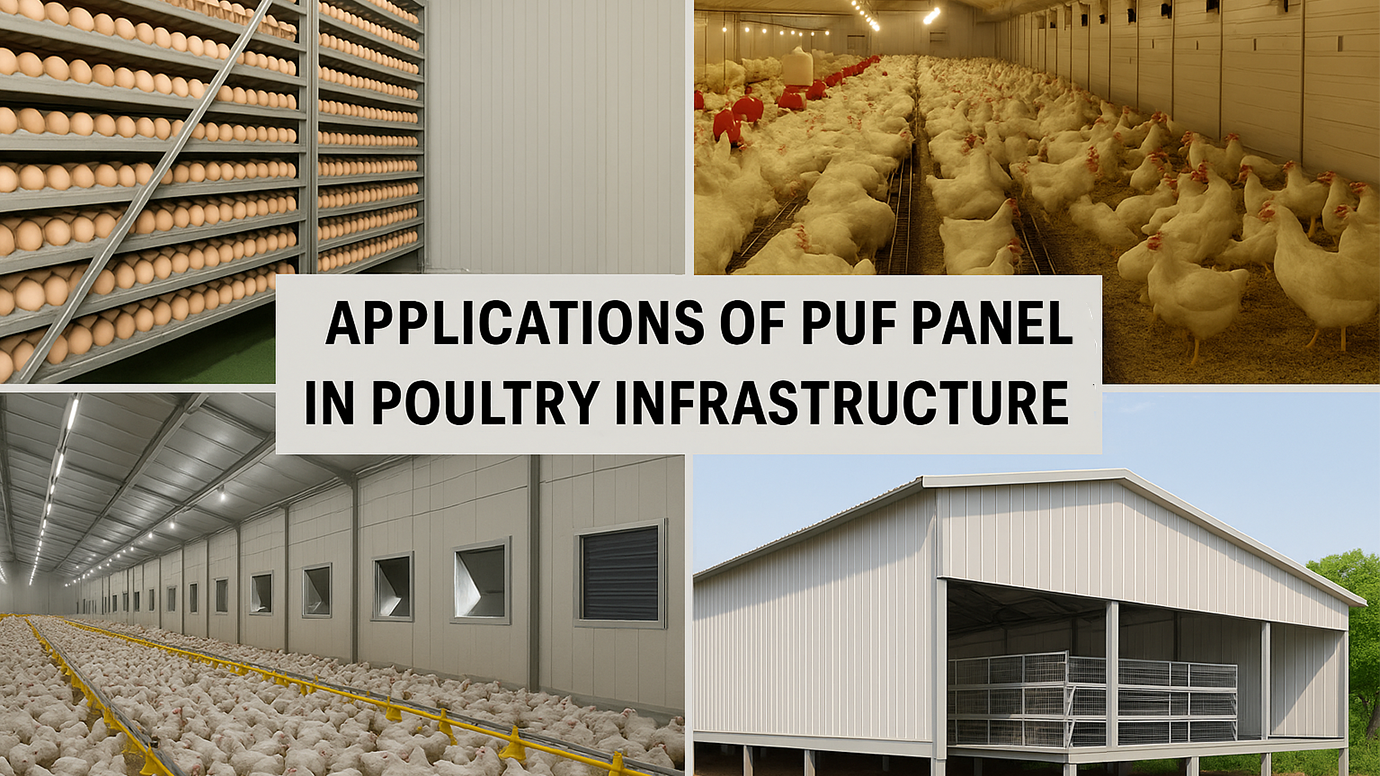

Applications of PUF Panels in Poultry Infrastructure

The versatility of PUF panels makes them the ideal building material for various components of a PUF Panel Poultry Farm. Their ability to provide insulation, hygiene, and structural durability ensures that every part of the poultry infrastructure contributes to better bird health, higher productivity, and lower operational costs. Below are the key applications of PUF panels across different types of poultry farms:

Layer Sheds (for Egg Production):

In a layer poultry farm, temperature regulation and hygiene are critical for maximizing egg production. PUF panels help maintain a stable climate inside layer sheds, ensuring that egg-laying hens are not stressed by heat or cold.

These panels also create a cleaner environment, which reduces the spread of disease and ensures a steady supply of high-quality eggs in egg farms and hen poultry farms. For those engaged in commercial layer farming, PUF-panelled poultry sheds provide an optimal setup for consistent yields.

Broiler Sheds (for Meat Birds):

A broiler poultry farm demands rapid weight gain and minimal stress for birds. Here, PUF panels play a critical role in creating insulated, draft-free poultry houses that encourage healthy growth.

Whether you're managing a large chicken farm or a mini farm focused on meat production, the use of PUF panels in broiler sheds helps improve feed conversion ratios and reduce mortality rates, boosting profitability for farmers.

Breeder Houses:

Breeder houses are essential for maintaining high-quality parent stock in any poultry farm. These birds require strict biosecurity, uniform ventilation, and optimal temperatures—all of which are supported by the use of PUF panels.

By constructing poultry houses for breeders with insulated panels, farmers ensure controlled environments that promote reproductive health and higher hatchability rates, reinforcing the foundation of any ideal poultry farm.

Hatcheries and Feed Storage Units:

Proper insulation and moisture resistance are critical in hatcheries and feed storage areas. Even small temperature fluctuations can affect embryo viability or spoil feed. PUF panels help maintain consistent interior conditions, reducing wastage and improving overall farm efficiency.

In a modern PUF Panel Poultry Farm, using PUF panels for feed storage units also prevents mold growth and pest infestation—common challenges in traditional storage facilities.

From layer poultry farms to single broiler farms, and from breeder housing to hatchery infrastructure, PUF panels are redefining what a truly modern poultry farm looks like. Their application across multiple components of the poultry shed ecosystem makes them a cornerstone of smart, scalable, and sustainable poultry production.

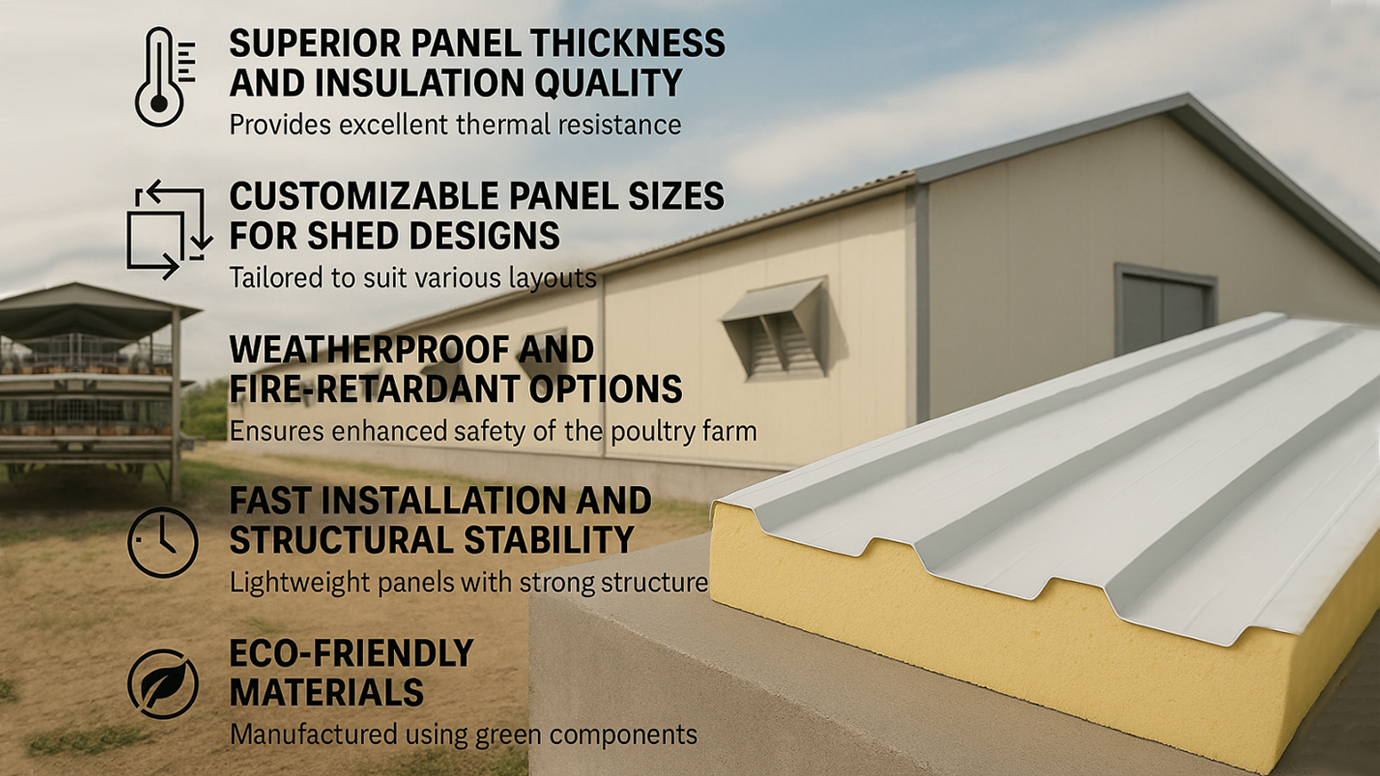

Key Features of PUF Panels for Poultry Farm

The efficiency and success of a poultry farm rely heavily on the quality of its infrastructure. As the backbone of any modern poultry, PUF panels are engineered to meet the demanding conditions of today’s chicken poultry farms. Their features are designed not just for functionality but to enhance performance, hygiene, and long-term cost savings.

Superior Panel Thickness and Insulation Quality:

One of the most vital characteristics of PUF panels is their superior insulation. Available in various thicknesses, these panels provide excellent thermal resistance, keeping the internal temperature of poultry houses stable throughout the year. Whether it’s a hen poultry farm in a hot climate or an egg hen farm in a colder region, PUF panels help maintain the ideal conditions for bird health and productivity.

This insulation quality directly impacts energy savings and bird performance, making them a must-have for an ideal poultry farm focused on maximizing yield and minimizing overhead.

Customizable Panel Sizes for Shed Designs:

Every poultry farm has unique spatial and functional needs. Whether you're operating a chicken farm or scaling up your layer farming setup, PUF panels can be tailored in size and dimensions to suit various poultry shed designs.

Customizability ensures efficient space utilization, improved airflow design, and seamless integration with ventilation systems — key elements for high-performing poultry houses in both small and large-scale farms.

Weather proof and Fire-Retardant Options:

Poultry farms are exposed to diverse weather conditions — from scorching heat to torrential rains. PUF panels are designed to be weather proof, providing solid resistance against moisture, UV rays, and corrosion. Additionally, fire-retardant options enhance the safety of the poultry farm, reducing fire hazards and providing peace of mind to farm operators.

This feature is particularly valuable for broiler poultry farms, where the density of birds and equipment requires robust safety measures.

Fast Installation and Structural Stability:

One of the most appreciated benefits of PUF panels is their lightweight yet strong structure, which enables quick installation without compromising on durability. This reduces construction time significantly, allowing chicken poultry farms, layer farms, and egg farms to begin operations faster.

Once installed, the panels provide exceptional structural stability, withstanding wind loads, impacts, and long-term wear — ideal for a busy chicken farm or high-turnover broiler poultry farm.

Eco-Friendly Materials:

Sustainability is becoming key consideration in the evolution of the modern poultry farm. PUF panels are manufactured using eco-friendly materials that minimize environmental impact during production and usage.

By incorporating green building materials into poultry houses, farm owners not only reduce their carbon footprint but also align with regulatory trends and consumer expectations around ethical farming.

In essence, the use of PUF panels in prefabricated labour camps not only streamlines construction and enhances camp functionality but also aligns with eco-friendly building strategies, making them an indispensable choice in contemporary construction projects. These advantages collectively enhance the efficiency, comfort, and sustainability of labour camps, reflecting the evolving priorities and innovations within the construction industry.

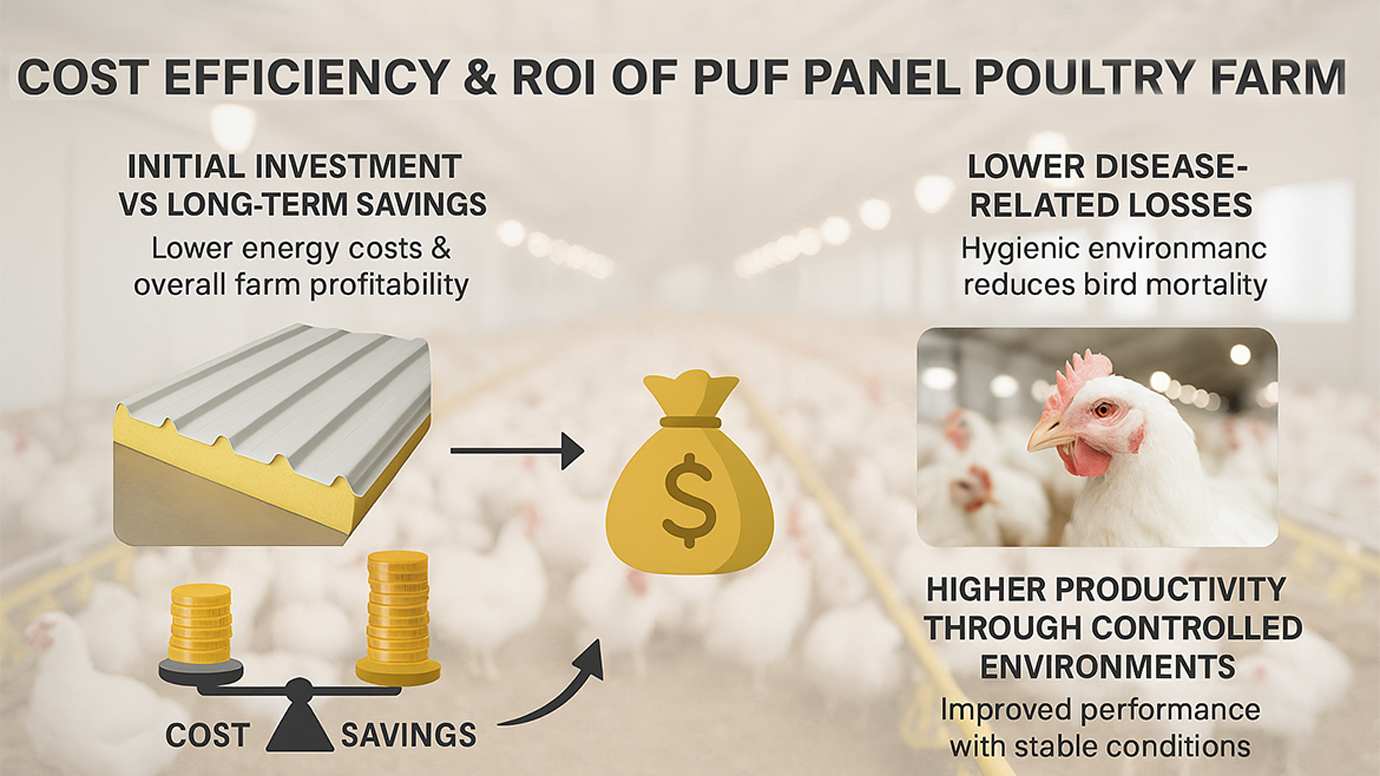

Cost Efficiency & ROI of PUF Panel Poultry Farm

Investing in a PUF Panel Poultry Farm is not just a choice for better infrastructure—it’s a strategic decision for long-term profitability. While the initial setup cost of using PUF panels in a poultry farm might be slightly higher compared to traditional materials, the long-term return on investment (ROI) significantly outweighs this initial expense. From lower energy consumption to reduced bird mortality, the financial advantages are both immediate and sustainable.

Initial Investment vs Long-Term Savings

The upfront cost of setting up a poultry using PUF panels includes high-quality materials, professional installation, and possible customization for different types of poultry houses. However, this one-time investment quickly translates into long-term savings due to reduced operational expenses.

In chicken poultry farms, energy efficiency plays a huge role in monthly costs. PUF panels significantly cut down on the need for air conditioning and heating, maintaining optimal temperatures in the poultry houses naturally. This leads to substantial savings on electricity bills—savings that accumulate month after month, boosting overall farm profitability.

Lower Disease-Related Losses

Disease outbreaks are a major concern in any chicken farm. Traditional poultry sheds are often susceptible to moisture buildup, bacterial growth, and poor sanitation—factors that increase the risk of infection and mortality.

In contrast, PUF Panel Poultry Farms offer a hygienic, sealed, and easy-to-clean environment that drastically reduces disease transmission. Fewer illnesses mean fewer losses, lower veterinary costs, and healthier flocks. This is particularly critical for high-stakes operations like broiler poultry farms and layer poultry farms, where even a small disease outbreak can cause significant revenue loss.

Higher Productivity through Controlled Environments

Productivity in a poultry farm is directly linked to the stability of the environment. Birds raised in temperature-controlled, low-stress, clean poultry houses show better feed conversion ratios, faster growth, and higher egg-laying rates. Whether it's a chicken farm focused on meat production or a layer poultry farm producing eggs, the use of PUF panels ensures ideal living conditions that lead to improved performance across the board.

In a PUF Panel Poultry Farm, you’re not just providing shelter—you’re engineering an environment designed for maximum output. More eggs, healthier broilers, and better weight gain mean greater market value and increased profitability.

For today’s poultry entrepreneurs, from small hen poultry farms to full-scale chicken poultry farms, investing in PUF panels is a forward-thinking move. By ensuring durability, efficiency, and bird welfare, PUF Panel Poultry Farms deliver strong financial returns while aligning with modern farming standards.

Why Choose Technopuff Solutions?

When it comes to building a durable, efficient, and future-ready PUF Panel Poultry Farm, choosing the right partner makes all the difference. Technopuff Solutions stands out as a trusted name in the industry, delivering unmatched quality and value to modern poultry farmers across the country. Whether you’re establishing a new poultry farm or upgrading an existing chicken poultry farm, our solutions are made to meet the evolving demands of today’s poultry industry.

Decades of Industry Experience

With deep-rooted expertise in insulated construction, Technopuff Solutions has years of hands-on experience in manufacturing high-performance PUF panels tailored for poultry farm applications. From compact hen poultry farms to large-scale broiler poultry farms, we understand the unique challenges farmers face—and we offer real solutions. Our panels are engineered specifically for the structural and environmental needs of poultry houses, ensuring reliability in every project.

Custom Manufacturing & Design Support

Every poultry shed is different. That’s why we offer custom manufacturing services to fit the exact dimensions & layout of your ideal poultry farm. Whether you’re setting up a climate-sensitive egg hen farm, an automated layer farming system, or a high-output chicken farm, our technical team works with you from the design phase to ensure that each poultry shed is optimized for performance, hygiene, and energy efficiency.

Our bespoke designs are perfect for specialized needs like layer poultry farms and broiler poultry farms, where productivity and bird health depend on tailored infrastructure solutions.

On-Time Delivery, Every Time

At Technopuff Solutions, we value your time and your business. That’s why we have a proven track record of on-time delivery for all PUF Panel Poultry Farm orders. From initial consultation to final dispatch, our supply chain is designed for speed and precision, ensuring that your poultry farm construction stays on schedule, with no costly delays.

Whether you're building a small chicken poultry farm or a sprawling commercial poultry farm, timely delivery helps you start operations faster and generate quicker returns on investment.

Technical Support & After-Sales Service

Our commitment to your success doesn’t end with delivery. We provide full-spectrum technical support and after-sales service to make sure your PUF Panel Poultry Farm performs at its best. From installation guidance to maintenance tips, our team is just a call away to support your poultry farm at every stage of its growth.

Farmers across various segments—be it egg farms, hen poultry farms, or hybrid layer poultry farms—trust Technopuff for ongoing technical reliability and peace of mind.

Choosing Technopuff Solutions means partnering with a company that puts innovation, quality, and customer satisfaction at the heart of everything we do. With tailor-made PUF panels, end-to-end support, and a deep understanding of modern poultry houses, we help you build an ideal poultry farm that’s efficient, profitable, and future-ready.

FAQs

A. A PUF Panel Poultry Farm uses insulated polyurethane foam (PUF) panels to build poultry houses that are energy-efficient, hygienic, and durable. These modern structures enhance bird health and farm productivity.

A. Yes, PUF panels are highly versatile and can be customized for small poultry farms or large-scale operations, offering reliable insulation and long-term durability.

A. PUF panels have smooth, non-porous surfaces that are easy to clean, reducing risk of contamination—crucial for chicken farms and egg farms.

A. Absolutely. Whether it’s layer farming in egg farming or meat production in a broiler poultry farm, PUF panels create controlled environments that boost performance and reduce mortality.

A. Yes, they are ideal for a new poultry farm, as they offer fast installation, customizable sizes, and modern features that meet the demands of today’s poultry industry.

A. The insulation properties of PUF panels keep the interior of the poultry shed cool in summer & warm in winter, which is essential for bird health in any poultry farm.

A. Yes, PUF panels are weatherproof and fire-retardant, providing strong protection against heat, rain, and wind—especially beneficial in open areas where many poultry houses are located.

A. Yes, at Technopuff Solutions, we provide custom-manufactured PUF panels to match the layout of your poultry farm shed, whether for an egg hen farm or a high-output broiler poultry farm.

A. Yes, PUF panels are ideal for expanding or upgrading a poultry farm. They integrate well with existing structures and bring modern performance enhancements to any chicken farm.

A. Thanks to their modular nature, PUF panels allow for quick installation, reducing setup time and helping you start or scale your poultry farm, or layer farm sooner.

Conclusion

The future of poultry farming is evolving—and PUF Panel Poultry Farm solutions are at the heart of this transformation. From reducing operational costs to improving bird health and boosting productivity, PUF panels offer a modern, sustainable, and high-performing alternative to conventional poultry shed construction.

Whether you run a chicken farm, a hen farm, or a fast-growing broiler farm, integrating PUF panels into your poultry houses leads to measurable improvements. Better insulation, superior hygiene, faster installation, and long-term durability make them a clear choice for every kind of operation—from small farms to expansive commercial units.

For those engaged in layer farming, egg hen farms, or building a new poultry farm, the benefits are even more pronounced. Controlled environments mean fewer disease outbreaks, better feed efficiency, and a higher return on investment. It’s no surprise that more and more farmers are choosing PUF Panel Poultry Farms as the foundation of their ideal poultry farm setup.

At Technopuff Solutions, we are proud to be enabling this next wave of innovation in modern poultry infrastructure. With custom-manufactured panels, expert design support, and dependable service, we help you build smarter, stronger, and more sustainable poultry farm sheds that stand the test of time.

We invite poultry entrepreneurs, agribusiness owners, and farm planners to connect with Technopuff Solutions today. Our team is here to help you design and deliver a modern poultry farm that aligns with your goals—whether you’re starting fresh or scaling up.

For more details about PUF Panels and other structures that can be constructed from it, go to our PUF Panels page.