PUF Panel Prefabricated Labour Camps

In the rapidly evolving landscape of construction, the emergence of prefabricated labour camps has marked a significant revolution, particularly in projects where speed, efficiency, and cost-effectiveness are paramount. Prefabricated labour camps are specialized residential units constructed using modular components that are mostly assembled or manufactured in a factory before being transported to the site. This method stands in contrast to traditional construction practices and offers a quick setup to accommodate workers near large construction or industrial sites, ensuring they have immediate access to safe and comfortable living quarters.

Among the various innovations enhancing the utility and efficiency of these camps, PUF (Polyurethane Foam) panels play a pivotal role. PUF panels are advanced building materials known for their exceptional insulation properties, lightweight nature, and superior durability. In the context of prefabricated labour camps, PUF panels are not just another component but a transformative element that significantly impacts the overall functionality and sustainability of these temporary homes.

The relevance of PUF panels in modern construction, especially in prefabricated labour camps, extends beyond simple utility. These panels facilitate a construction process that is not only faster but also less labor-intensive and can considerably reduce the overall carbon footprint of a building project. Their thermal insulation capabilities make them particularly suited to diverse climatic conditions, ensuring comfort for occupants while minimizing energy consumption for heating and cooling. This aligns with the increasing demand for more sustainable construction practices across the globe.

By integrating PUF panels, prefabricated labour camps are set to redefine construction timelines and quality standards, providing a replicable model for rapid and responsible building practices in numerous sectors.

Understanding Prefabricated Labour Camps

Prefabricated labour camps are specialized residential solutions designed to provide immediate, efficient, and cost-effective accommodation for workers involved in large-scale construction and industrial projects. These camps are comprised of various pre-built modules, which include sleeping quarters, dining facilities, and sanitation services. The modules are constructed in a controlled factory setting and then transported to the job site, where they are rapidly assembled into a fully functional residential compound.

The importance of labour camps cannot be overstated in the context of major construction and industrial initiatives. These projects often occur in remote or undeveloped areas where traditional accommodation facilities are either inadequate or non-existent. Labour camps play a critical role in such scenarios, providing workers with safe, comfortable, and accessible living spaces close to their work areas. This proximity is crucial for maintaining high productivity levels and can significantly reduce the daily commute, thereby saving time and reducing transportation costs.

Benefits of Using Prefabrication Technology in Building Labour Camps

The benefits of using prefabrication technology in building labour camps are manifold.

- Firstly, the speed of construction is dramatically increased. Unlike traditional construction methods, which can be subject to delays due to weather conditions, supply chain issues, and labor shortages, prefabrication allows for much of the work to be completed off-site. This not only speeds up the overall project timeline but also enhances the quality control during the manufacturing of the modules.

- Additionally, prefabricated labour camps are inherently more flexible than their built-from-scratch counterparts. They can be easily expanded, reconfigured, or relocated to suit the changing needs of a project or to be reused in different locations. This flexibility ensures that resources are utilized more efficiently, reducing waste and the environmental impact associated with building new structures from the ground up.

- Economically, prefabrication technology offers substantial cost savings. The controlled factory environment reduces the wastage of materials and enables more accurate budgeting and fewer financial discrepancies. Furthermore, the labor costs are often lower, as the more complex parts of construction occur in a factory setting, requiring fewer skilled workers on site.

In summary, prefabricated labour camps represent a pivotal innovation in the field of construction and industrial project management. By leveraging the advantages of prefabrication technology, these camps not only improve the living conditions of workers but also contribute to the more strategic use of resources, enhancing the overall efficiency and sustainability of large-scale projects.

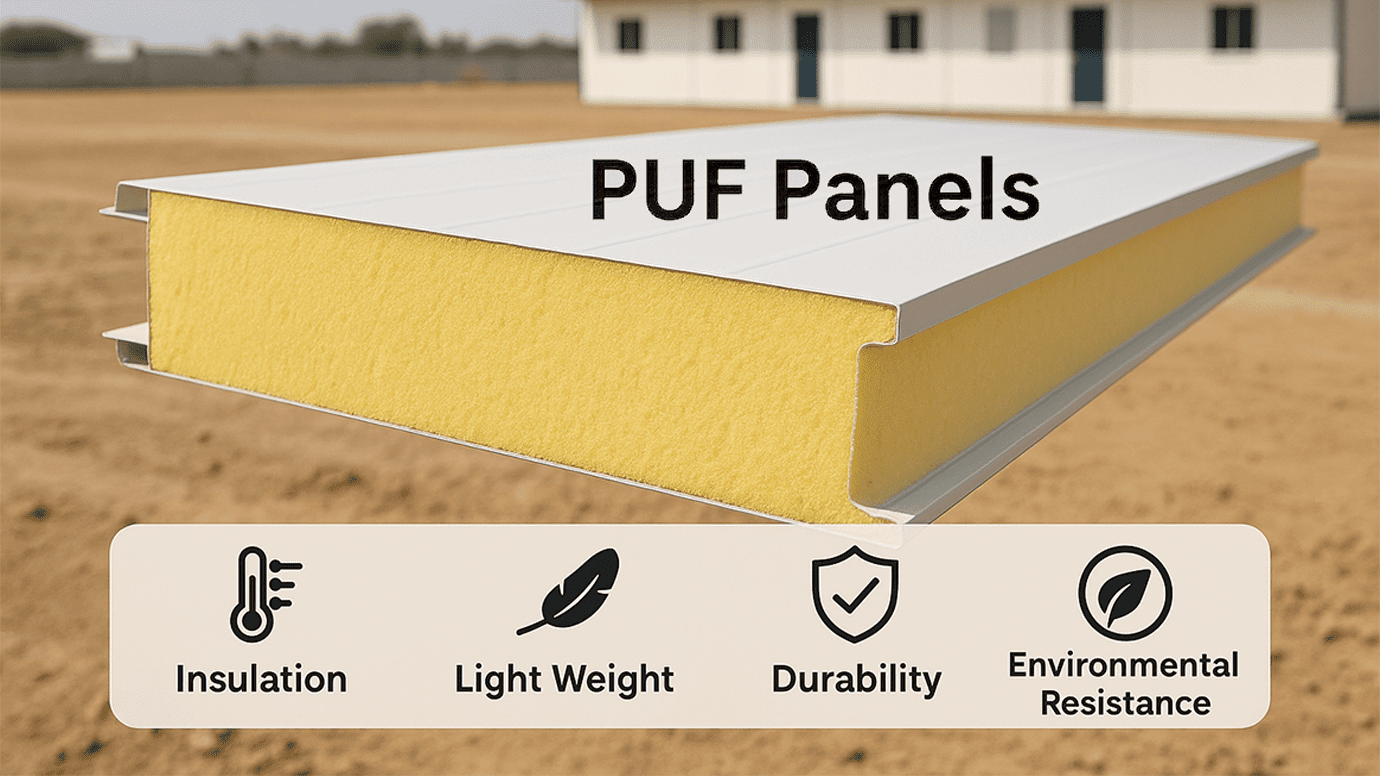

What are PUF Panels?

In the construction of prefabricated labour camps, one of the most innovative materials used today are PUF (Polyurethane Foam) Panels. These panels serve as essential components that drastically improve the efficiency, comfort, and sustainability of temporary housing solutions in various industrial settings.

PUF panels are advanced composite building materials made from polyurethane foam sandwiched between layers of structural facings. This foam is a type of highly efficient thermal insulating material that expands and cures into a solid foam state, providing exceptional heat and sound insulation. The outer layers are typically made from materials like steel, aluminium, or fiberglass, which add structural integrity and protection to the inner foam core.

The key properties of PUF panels that make them highly sought after in the construction of prefabricated labour camps include:

Insulation

PUF panels offer superior thermal resistance, significantly reducing the need for additional heating or cooling in labour camps, which can be crucial in extreme weather conditions.

Lightweight

The inherent lightweight nature of these panels makes them easy to transport and assemble, reducing the overall construction time and labor costs associated with traditional building materials.

Durability

Despite their light weight, PUF panels are extremely durable. They are resistant to mold, mildew, and corrosion, which prolongs the lifespan of prefabricated labour camps and reduces maintenance needs.

Environmental Resistance

PUF panels perform well under various environmental stressors, including temperature fluctuations, humidity, and even chemical exposures, making them ideal for harsh worksite conditions.

When compared to other building materials traditionally used in labour camps, such as wood, concrete, or brick, PUF panels offer several distinct advantages. Traditional materials, while robust, often require more complex and time-consuming construction techniques, are heavier, and less efficient in terms of insulation. They also typically involve more labor-intensive assembly processes and do not provide the same level of flexibility as PUF panels.

For instance, wood is susceptible to termite infestation and rot, concrete can crack and requires significant curing time, and bricks, though durable, add considerable weight and require skilled labor for construction. PUF panels, on the other hand, eliminate many of these issues with their advanced engineering, providing a quick, reliable, and highly efficient building solution for prefabricated labour camps.

In essence, the adoption of PUF panels in the construction of labour camps not only enhances the living conditions within these temporary accommodations but also promotes a more sustainable and economically viable approach to building. These panels are paving the way for a new era in the construction industry where efficiency, durability, and cost-effectiveness are paramount.

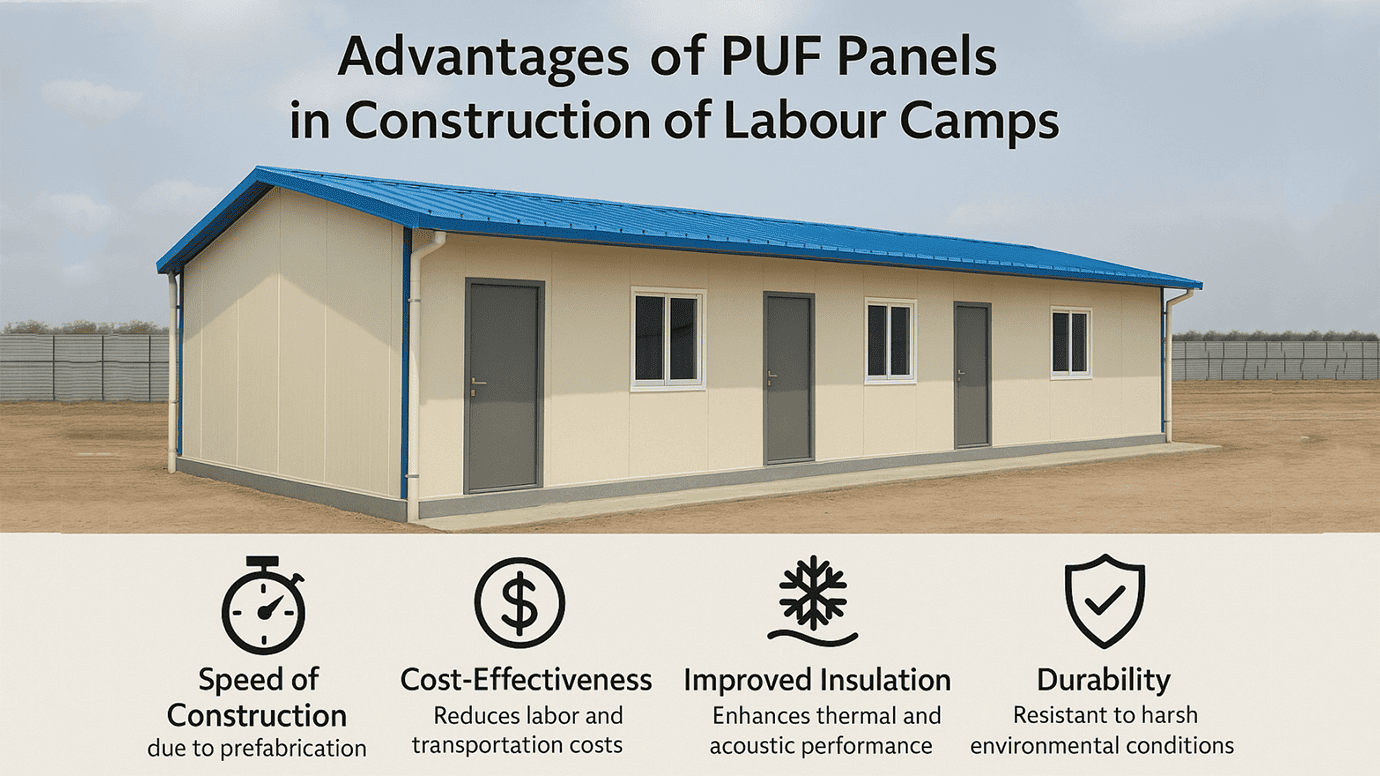

Advantages of PUF Panels in Construction of Labour Camps

The integration of PUF (Polyurethane Foam) panels into the construction of prefabricated labour camps presents a suite of compelling benefits, streamlining construction processes and improving camp conditions significantly. These advantages align well with the needs of fast-paced and budget-conscious construction projects, making prefabricated labour camps increasingly preferred in modern construction settings.

Speed of Construction

One of the standout advantages of using PUF panels in the construction of prefabricated labour camps is the acceleration of building timelines. Prefabrication of these panels allows for rapid assembly on-site, dramatically reducing the time from start to finish compared to traditional building methods. This efficiency is essential for labour camps, where quick setup is often critical to the success of construction and industrial projects.

Cost-Effectiveness and Economic Benefits

Economically, the use of PUF panels in prefabricated labour camps brings substantial cost savings. The prefabrication process reduces the need for skilled labor on-site and shortens project durations, both of which contribute to lowering labor costs. Additionally, the lightweight nature of PUF panels decreases transportation expenses. The factory-based assembly also minimizes waste production, further optimizing the cost efficiency of prefabricated labour camps.

Improved Thermal and Acoustic Insulation Properties

PUF panels enhance the living environment within prefabricated labour camps through superior thermal and acoustic insulation. This insulation helps maintain optimal indoor temperatures, reducing the reliance on external heating and cooling devices and thereby conserving energy. The acoustic insulation properties ensure that the interior of the labour camps remains quiet, providing a peaceful retreat from the bustling activity typical at construction sites.

Durability and Resistance to Environmental Factors

The durability of PUF panels is critical for their application in prefabricated labour camps. These panels are engineered to resist harsh environmental conditions such as extreme temperatures, moisture, and corrosion—common challenges at remote construction sites. The robustness of PUF panels guarantees the longevity of labour camps, minimizing the need for ongoing maintenance and replacements.

Energy Efficiency and Sustainability Aspects

Finally, the energy efficiency and sustainable characteristics of PUF panels underscore their role in promoting environmentally friendly practices in the construction of prefabricated labour camps. The excellent insulation properties of the panels significantly cut down energy usage for climate control within the camps, leading to lower energy bills and a reduced environmental impact. Utilizing PUF panels supports the construction industry's shift towards more sustainable building practices, emphasizing the ecological benefits of modern prefabricated labour camps.

In essence, the use of PUF panels in prefabricated labour camps not only streamlines construction and enhances camp functionality but also aligns with eco-friendly building strategies, making them an indispensable choice in contemporary construction projects. These advantages collectively enhance the efficiency, comfort, and sustainability of labour camps, reflecting the evolving priorities and innovations within the construction industry.

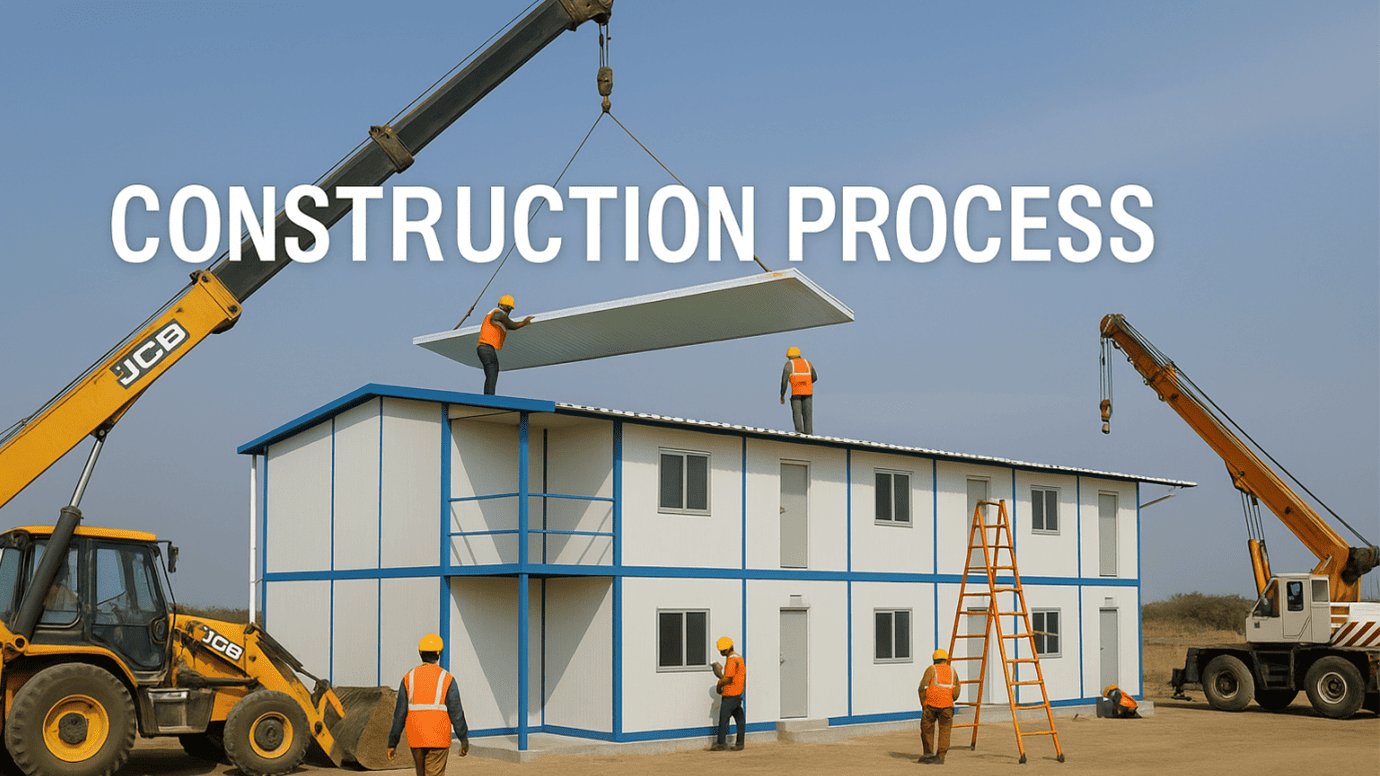

Construction Process of Prefabricated Labour Camps Using PUF Panels

The construction of prefabricated labour camps using PUF panels is a streamlined process that showcases the efficiency and effectiveness of modern building techniques. This method not only accelerates the building timeline but also ensures high-quality outcomes. Here, we outline the detailed phases involved in constructing these prefabricated labour camps and compare the timeframe with traditional construction methods to highlight the advantages of using PUF panels.

Step-by-Step Construction Process

- Design and Pre-Planning: This initial phase is critical for the successful setup of prefabricated labour camps. It involves creating detailed blueprints that not only optimize space and material use but also consider environmental impacts and logistical aspects. Effective design directly influences the efficiency and sustainability of labour camps.

- Manufacturing of PUF Panels: In the controlled environment of a factory, PUF panels are produced by injecting polyurethane between protective layers. This process is engineered to produce panels that provide robust insulation and structural reliability, essential qualities for labour camps exposed to diverse environmental conditions.

- Site Preparation and Foundation Work: Concurrent with the production of PUF panels, the construction site for the labour camps is prepared. This step includes laying a stable foundation, which, although lighter than those required for traditional buildings, must support the assembled structure effectively.

- Transporting PUF Panels to Site: The lightweight PUF panels are transported to the construction site, optimizing logistics and reducing transportation costs—key factors in maintaining the cost-efficiency of building prefabricated labour camps.

- Assembly of Panels: Using cranes and specialized equipment, the PUF panels are assembled on-site. This phase transforms the flat-packed panels into three-dimensional structures of the labour camps, with workers using advanced tools to secure panels swiftly and securely, thus forming the basic structure of the camp.

- Finishing Touches: Post-assembly, the labour camps are outfitted with necessary utilities and finishes. This includes installing electrical and plumbing systems, and applying internal and external finishes to improve the durability and livability of the camps.

Tools and Technologies Used

Building prefabricated labour camps with PUF panels involves specific tools and technologies designed for efficiency. Heavy lifting equipment, precision fastening tools, and sealing technologies are crucial for quick and reliable assembly. Moreover, modern construction management software aids in streamlining every stage, from panel fabrication to final assembly.

Role of Design and Pre-Planning

In the construction of prefabricated labour camps, robust design and strategic pre-planning are indispensable. These elements ensure that every aspect of the labour camps is optimized for quick assembly, cost efficiency, and long-term durability. Good pre-planning minimizes on-site challenges, accelerates construction timelines, and ensures that the labour camps meet both functional and environmental standards.

Overall, the process of constructing prefabricated labour camps using PUF panels is a testament to modern construction practices that prioritize speed, efficiency, and adaptability. These attributes are essential in responding to the dynamic needs of large-scale construction projects and industrial applications.

Future Trends and Innovations in Prefabricated Labour Camps

The landscape of prefabricated labour camps is constantly evolving, driven by advancements in technology and a growing emphasis on sustainability. This section explores the cutting-edge technologies reshaping labour camps, potential developments in PUF panel technology, and the increasing influence of green building standards in the industry.

Emerging Technologies in the Prefabrication of Labour Camps

Innovations in the prefabrication sector are revolutionizing how prefabricated labour camps are designed, manufactured, and assembled. One key area of advancement is in modular construction technology, which allows for more complex and customizable designs while maintaining the benefits of prefabrication such as speed and efficiency. Additionally, the integration of digital tools like Building Information Modeling (BIM) is enhancing the precision in the design and construction processes, enabling better planning and management of labour camps. These technologies ensure that prefabricated labour camps are not only built faster but also with greater accuracy and less waste.

Potential Future Developments in PUF Panel Technology

PUF panel technology, already known for its excellent insulation properties and structural integrity, is expected to see significant enhancements. Future developments may focus on improving the fire resistance and acoustic properties of these panels, making them even safer and more comfortable for occupants of prefabricated labour camps. Research is also being directed towards making PUF panels lighter and more environmentally friendly by incorporating recycled materials and reducing the use of chemicals that impact the environment.

The Role of Green Building Standards and Sustainability in Future Developments

Sustainability is becoming a cornerstone in the construction of prefabricated labour camps. The industry is increasingly adopting green building standards, such as LEED and BREEAM, which evaluate the environmental impact and sustainability of construction projects. For prefabricated labour camps, this means integrating energy-efficient systems, using materials that are sustainably sourced and recyclable, and implementing designs that reduce the overall carbon footprint. The future will likely see these practices becoming the norm, as the benefits of sustainability gain recognition not only for environmental reasons but also for the long-term economic advantages they bring.

Furthermore, the push towards sustainability in prefabricated labour camps is expected to drive innovation in energy management technologies, such as the use of solar panels and advanced HVAC systems that are more energy-efficient. This not only aligns with global sustainability goals but also enhances the self-sufficiency of labour camps, particularly in remote or off-grid locations.

The future of prefabricated labour camps looks promising with numerous innovations on the horizon. These developments are poised to make labour camps safer, more comfortable, and more sustainable, reflecting broader trends in the construction industry towards efficiency and responsibility. As technology advances and sustainability becomes even more crucial, prefabricated labour camps will continue to evolve, setting new standards in construction practices.

FAQs

A. Prefabricated labour camps are temporary housing facilities constructed using modular components that are pre-built in a factory setting and assembled on-site. They are primarily used to house workers on large-scale construction and industrial projects.

A. PUF panels are chosen for prefabricated labour camps due to their excellent thermal and acoustic insulation, lightweight nature, and durability. These properties ensure efficient, cost-effective, and comfortable accommodations for workers.

A. The prefabrication of PUF panels allows for rapid assembly on-site, significantly reducing the construction timeline of labour camps compared to traditional building methods.

A. Using PUF panels in labour camps leads to cost savings through reduced labor costs, lower transportation expenses, and minimized material wastage due to the controlled factory environment where they are produced.

A. Yes, the superior insulation properties of PUF panels minimize the need for heating and cooling in labour camps, thereby reducing energy consumption and enhancing overall energy efficiency.

A. PUF panels contribute to sustainability by reducing the energy footprint of labour camps and often incorporate recyclable materials, aligning with green building standards.

A. PUF panel labour camps require minimal maintenance as the panels are durable and resistant to environmental factors such as moisture and temperature extremes.

A. PUF panels offer better insulation, are lighter, and provide quicker assembly advantages over traditional materials like wood, concrete, or brick, which are heavier and require more time-consuming construction techniques.

A. Technopuff Solutions is known for its expertise in integrating PUF panel technology with robust construction practices, ensuring rapid deployment and high-quality prefabricated labour camps.

Conclusion

The adoption of PUF panels in the construction of prefabricated labour camps marks a significant advancement in the field, offering substantial benefits that enhance both the efficiency and sustainability of these essential facilities. These panels are celebrated for their superior thermal insulation, durability, and lightweight nature, which streamline the construction process and reduce overall project timelines. Furthermore, the cost-effectiveness and energy efficiency of PUF panels not only minimize operational expenses but also align with contemporary environmental standards, setting a new benchmark in the construction of labour camps.

Looking to the future, the prefabricated labour camps sector is poised for further innovation, driven by advancements in PUF panel technology and a growing commitment to green building practices. Enhanced material properties, integration with renewable energy systems, and adherence to stringent sustainability criteria are expected to propel the functionality and eco-friendliness of labour camps to new heights. This progressive trajectory suggests a dynamic evolution of the industry where efficiency, eco-consciousness, and technological innovation converge to redefine what is possible in construction.

In this context, Technopuff Solutions emerges as a key player, ready to meet the demands of this evolving market. We extend an invitation to all stakeholders in construction and industrial projects to explore the services offered by Technopuff Solutions. Whether you are seeking an enquiry, require a detailed quotation, or need specialized construction and installation services for PUF Panel Prefabricated Labour Camps, our team is equipped to deliver top-tier solutions. Engaging with Technopuff Solutions means partnering with a leader in innovative, quality, and customer-focused construction practices.

Reach out to Technopuff Solutions and take advantage of our expertise in deploying prefabricated labour camps that not only meet but exceed the modern construction standards. Join us in driving forward the future of construction, where smart, sustainable, and swift building solutions are not just envisioned but executed with precision. To know more about other structures, go to our Prefabricated Shelters page.