Normal PUF Panels vs Fire Retardant PUF Panels: Which One is Right for Your Project?

When it comes to modern construction and insulation needs, Normal PUF Panels vs Fire Retardant PUF Panels is a topic that often comes up among architects, builders, and project planners. Both solutions are highly effective in their own ways and are widely used to build everything from industrial warehouses to clean rooms, cold storages, prefabricated houses, and more.

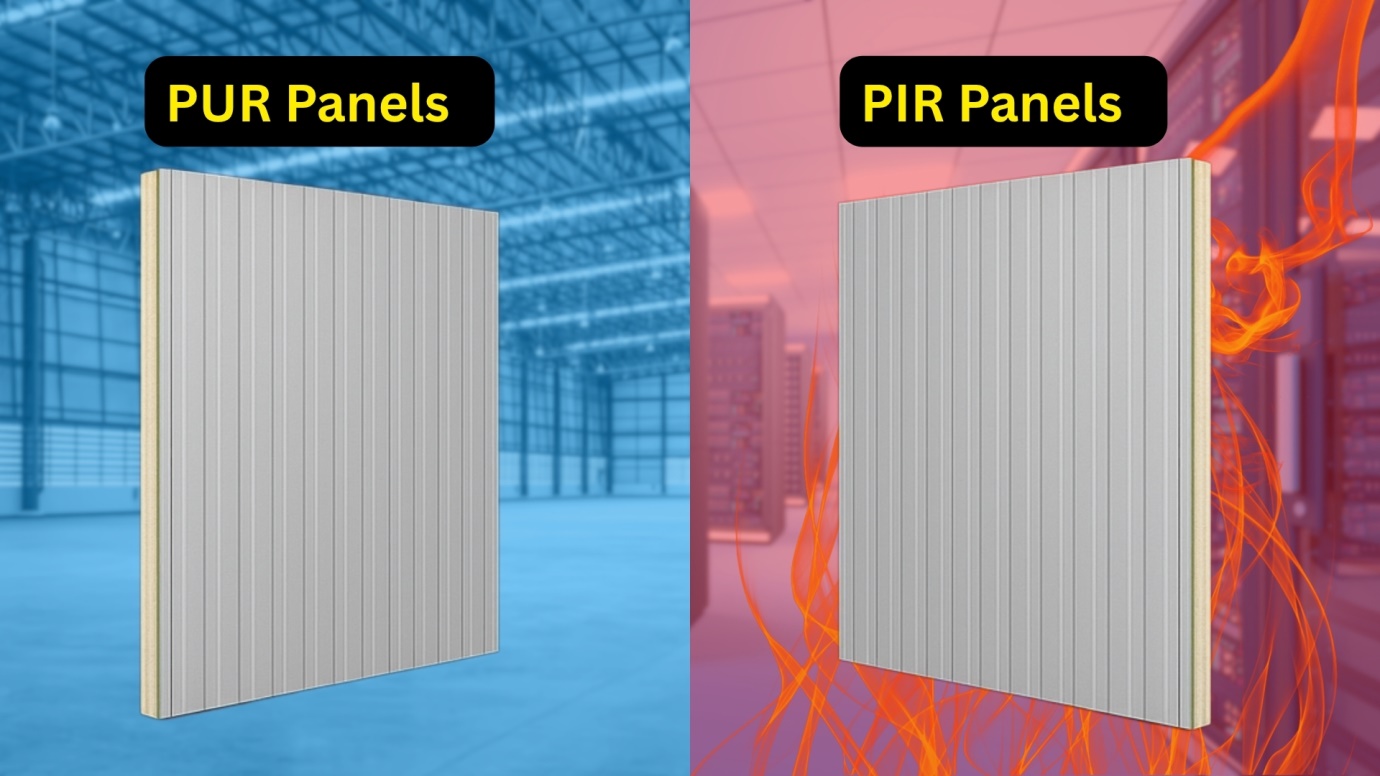

At Technopuff Solutions, we specialize in manufacturing both PUR Panels (Normal PUF Panels) and PIR PUF Panels (Fire Retardant PUF Panels), ensuring that every project gets the perfect balance of safety, durability, and performance.

A fire resistant panel plays a critical role in environments where safety and compliance are first priorities, while PUR Panels offer excellent insulation performance at an economical cost. Similarly, PIR PUF Panels are becoming increasingly popular for industries that demand higher fire resistance to meet strict building codes and protect valuable infrastructure.

The goal of this blog is simple: to give you a clear, easy-to-understand comparison of Normal PUF Panels and Fire Retardant PUF Panels. By the end, you’ll know exactly which panel fits your project best—without compromise.

What are PUF Panels?

PUF Panels, also known as Polyurethane Foam Panels, are advanced building materials designed to provide strength, durability, and insulation in a single product. They are widely used in modern construction because they combine metal sheets with an insulating foam core, making them highly efficient and versatile.

Structure of PUF Panels

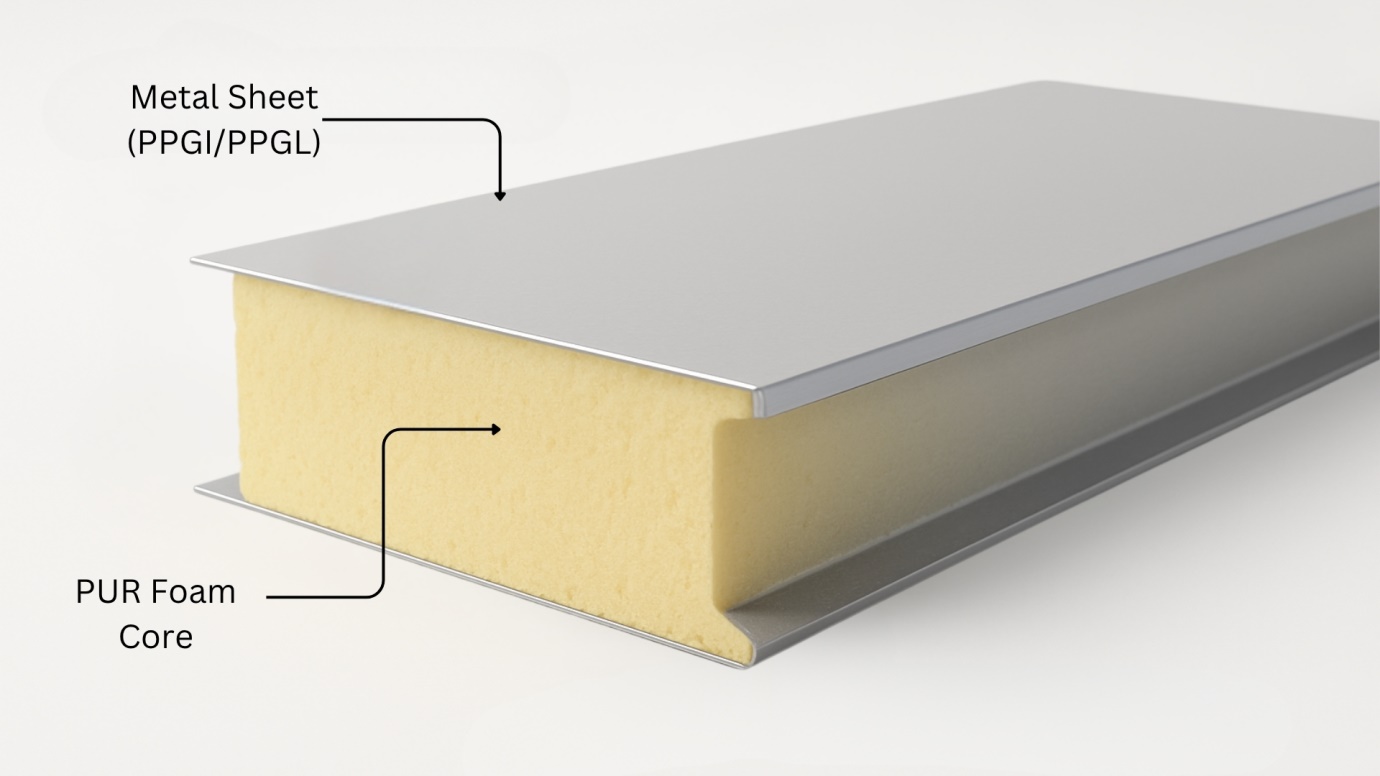

A typical PUF Panel is a sandwich panel made up of:

- Outer Skin: Pre-painted Galvanized Iron (PPGI) or Pre-painted Galvalume (PPGL) sheet for durability and corrosion resistance. Not sure whether to choose PPGI or PPGL sheets for your project? Explore our detailed blog on PPGI vs PPGL Sheets to understand their differences, benefits, and best applications.

- Core Material: Rigid polyurethane foam (PUR) or polyisocyanurate foam (PIR) depending on the application.

- Inner Skin: Similar protective sheet that adds to the panel’s strength and aesthetics.

This unique sandwich construction makes PUF Panels lightweight yet incredibly strong.

Key Advantages of PUF Panels

Whether you choose PUR Panels or PIR PUF Panels, both bring a wide range of benefits to construction projects:

- Lightweight – Easy to handle & transport, reducing labor costs.

- Strong & Durable – High load-bearing capacity with long-lasting performance.

- Excellent Thermal Insulation – Keeps interiors cooler in summer and warmer in winter, saving energy.

- Fire Resistance – Especially with PIR PUF Panels, you get improved fire resistant panel performance.

- Versatile Applications – From fire resistant wall panels in industrial setups to cold storage and prefabricated houses.

In short, PUF Panels are not just building blocks but high-performance insulated wall and roof solutions that combine efficiency, safety, and cost-effectiveness in one package.

What Are Normal PUF Panels (PUR Foam Core)?

Normal PUF Panels, also referred to as PUR Panels, are insulated sandwich panels made using a PUR foam core. The core is created from polyurethane foam, which is known for having superior thermal insulation properties and lightweight structure. These panels are constructed with an outer and inner metal skin—usually PPGI or PPGL sheets—and the rigid PUR foam in between, forming a PUR Sandwich Panel.

This Panel design ensures that the structure is not only insulated but also strong, durable, and long-lasting.

Key Features of Normal PUF Panels

Choosing PUR Panels for your project comes with multiple benefits that balance cost-effectiveness with performance:

- Superior Thermal Insulation – The PUR foam core minimizes heat transfer, helping maintain stable internal temperatures.

- Lightweight & Durable – Despite being lightweight, a PUR Panel has excellent structural strength, making it easy to transport and install.

- Cost-Effective Solution – Among different sandwich panel options, PUR Sandwich Panel is budget-friendly, offering excellent performance at a lower initial investment.

- Versatility – A Sandwich Panel can be used for multiple construction needs, from roofing to wall cladding.

Best Suited Applications

Normal PUF Panels (PUR-based) are widely used in industries and infrastructure projects where thermal efficiency and affordability are key:

- Cold Storage & Refrigeration Units – For maintaining controlled environments.

- Warehouses & Industrial Buildings – Providing insulation and structural support.

- Prefabricated Shelters & Portable Cabins – Quick to assemble and energy-efficient.

- Roofing & Wall Cladding – Lightweight yet strong solutions for modern buildings.

In short, PUR Panels are the go-to choice when projects demand thermal insulation, strength, and cost-effectiveness without compromising on versatility.

What Are Fire Retardant PUF Panels (PIR Foam Core)

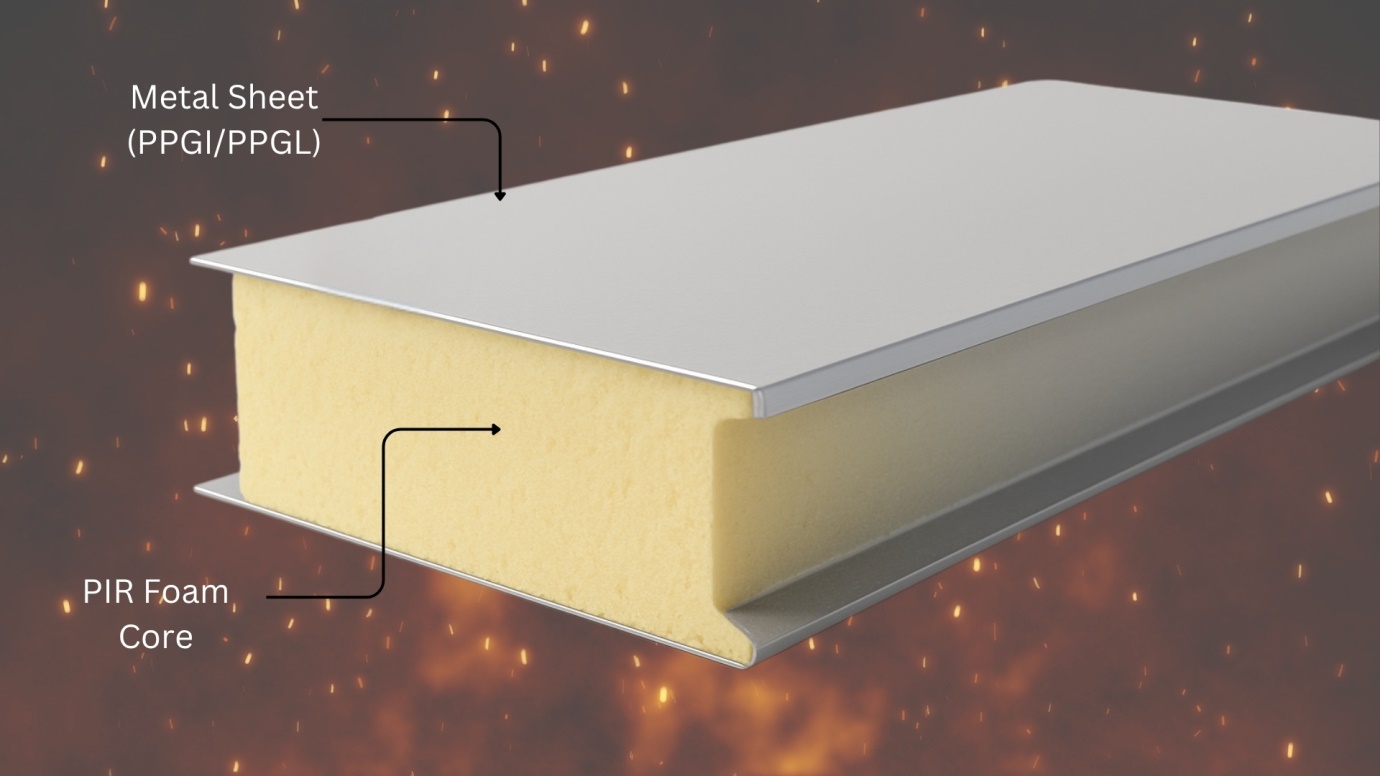

Fire Retardant PUF Panels are advanced insulated panels designed with a PIR Core (Polyisocyanurate foam). Unlike conventional PUR panels, PIR Panels are manufactured with a special chemical composition that creates highly cross-linked isocyanurate bonds. This unique structure makes a PIR Core Panel more stable at high temperatures and significantly improves its fire-retardant properties.

By combining durable metal skins (PPGI or PPGL) with a PIR foam core, these panels provide both superior insulation and outstanding fire protection. Whether used as a PIR Sandwich Panel or customized PUR Panel, they deliver unmatched safety and performance in critical environments.

Key Features of Fire Retardant PUF Panels

Fire safety is a top priority in today’s construction standards. PIR PUF Panels stand out because of their enhanced protection features:

- Enhanced Fire Safety – As a fire resistant panel, PIR foam resists ignition and forms a protective char layer, preventing fire spread.

- Low Smoke Emission – Compared to standard PUR, PIR Core Panels release much lower smoke, ensuring safety during emergencies.

- High Temperature Resistance – A PIR Sandwich Panel can withstand temperatures up to ~200°C, far higher than conventional PUR panels.

- Reliable Insulation – These panels double up as fire resistant panels, keeping interiors thermally stable while ensuring safety.

- Durability & Strength – Like any premium fire retardant panel maintain structural integrity even in demanding environments.

Best Suited Applications

Because of their fire retardant nature and robust performance, PIR PUF Panels are preferred in industries and facilities where both insulation and safety are critical:

- Pharma Clean Rooms – Ensures contamination-free, temperature-controlled environments.

- Food Processing Facilities – Protects sensitive products while meeting safety standards.

- Data Centers – Safeguards valuable IT infrastructure with fire resistant panels.

- Commercial Kitchens – Ideal as fire retardant wall panels to prevent fire hazards.

- Oil & Gas Sites – Provides insulation and fire protection in high-risk industries.

In summary, PIR Core Panels deliver superior performance as both fire resistant panels and high-quality insulation. Choosing a PIR Sandwich Panel means choosing safety, reliability, and compliance—making them the perfect solution for fire-sensitive and high-value projects.

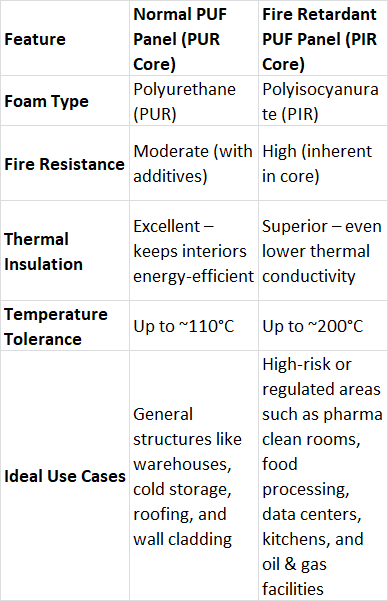

Comparison Table: Normal PUF vs Fire Retardant PUF Panels

When choosing between Normal PUF Panels (PUR-based) and Fire Retardant PUF Panels (PIR-based), it’s not about one being better than the other—it’s about selecting the right solution for your project’s requirements. Both panels deliver excellent insulation and structural strength, but their performance varies in terms of fire resistance, temperature tolerance, and specialized applications.

Here’s a clear comparison to help you understand the differences:

Feature | Normal PUF Panel (PUR Core) | Fire Retardant PUF Panel (PIR Core) |

Foam Type | Polyurethane (PUR) | Polyisocyanurate (PIR) |

Fire Resistance | Moderate (with additives) | High (inherent in core) |

Thermal Insulation | Excellent – keeps interiors energy-efficient | Superior – even lower thermal conductivity |

Temperature Tolerance | Up to ~110°C | Up to ~200°C |

Ideal Use Cases | General structures like warehouses, cold storage, roofing, and wall cladding | High-risk or regulated areas such as pharma clean rooms, food processing, data centers, kitchens, and oil & gas facilities |

Key Takeaways

- Normal PUR Panels (also known as PUR Sandwich Panel) are the go-to choice when cost-effectiveness and reliable thermal insulation are priorities.

- Fire Retardant Panels with PIR Core excel in environments where fire resistance and compliance with strict safety standards are non-negotiable.

- Both deliver excellent performance, but their application areas differ—making it important to align the choice with project needs.

In summary, whether you choose a PUR Panel or a PIR Fire Resistant Panel, you are investing in strength, durability, and energy efficiency.

How to Choose the Right Panel for Your Project

When deciding between PUR Panels and PIR PUF Panels, it’s not about which one is “better.” Both have their own strengths—it’s all about choosing the purpose-fit solution for your project. A PUR Sandwich Panel may be ideal for general insulation needs, while a PIR Sandwich Panel with a PIR Core is best suited for environments that require a fire resistance.

Key Considerations Before You Decide

Here are some important questions that can help guide your choice:

Q. Is the building in a fire-sensitive zone?

- If your project is in an area where fire safety is critical (such as kitchens, oil & gas facilities, or regulated industries), opting for a Fire Retardant Panel makes sense. The PIR Core provides better fire resistant insulation panels performance compared to conventional PUR.

Q. Are you storing temperature-sensitive goods?

- For cold storage, warehouses, or prefabricated shelters, PUR Panels are highly effective. A PUR Sandwich Panel offers excellent thermal insulation and cost efficiency, making it a popular choice for general construction.

Q. What are the applicable building codes and safety standards?

- Certain industries, like pharmaceuticals, food processing, or data centers, require compliance with strict safety regulations. In these cases, a Fire Resistant Panel will ensure long-term reliability and compliance. For projects with standard insulation needs, a Sandwich Panel PUR is more than sufficient.

Purpose-Fit Solutions

Whether it’s for coastal resorts, industrial zones, or rooftop structures, our PPGL sheet-based panels are engineered to endure and perform.

Why Choose Technopuff Solutions?

When it comes to insulated wall and roof solutions, choosing the right manufacturing partner is just as important as selecting the right panel. At Technopuff Solutions, we take pride in being one of the few companies with the expertise and capability to manufacture both Normal PUF Panels (PUR-based) and Fire Retardant PUF Panels (PIR-based). This dual capability allows us to serve a wide range of industries with reliable, custom-engineered solutions.

Expertise in Both PUR and PIR Panels

- PUR Panels – Known for their cost-effectiveness and excellent insulation properties. Whether you need a PUR Panel or PUR Sandwich Panel, we ensure high-quality performance suitable for warehouses, cold storages, and general structures.

- PIR Panels – Built with a PIR Core, these advanced solutions are designed for high-risk environments. A PIR PUF Panel functions as a superior fire resistance, providing safety and compliance in industries where fire safety are a must.

Expertise in Both PUR and PIR Panels

Every Fire Retardant Panel or Normal PUFPanel we manufacture undergoes strict quality checks to meet international standards. From raw material selection to final finishing, we focus on durability, structural integrity, and long-term performance.

We also provide:

- Engineering Support – Helping you select the right panel type based on technical needs.

- Nationwide Delivery – Ensuring that your panels reach you on time, anywhere in India.

- Custom Solutions – From PUR Panels for standard projects to PIR Sandwich Panels for specialized applications, we design panels to match your exact requirements.

Whether you are looking for energy-efficient PUR Panels or safety-driven Fire Resistant Panels, Technopuff Solutions is here to guide you. Our team not only manufactures panels but also helps clients understand which option is most suitable for their project—be it a PUR Panel for general use or a PIR Panel for high-safety zones.

In short, with Technopuff Solutions, you don’t have to choose between performance and safety—you get both. From PUR Panels to PIR Sandwich Panels, we deliver insulation solutions that combine technology, trust, and innovation.

FAQs

A. The main difference lies in the foam core. PUR Panels (Polyurethane) provide excellent thermal insulation and cost-effectiveness, while PIR Panels (Polyisocyanurate) are designed with a PIR Core that offers enhanced fire resistance and higher temperature tolerance.

A. Yes, a PUR Sandwich Panel delivers excellent thermal insulation, keeping interiors energy-efficient. They are commonly used in cold storage, warehouses, and prefabricated shelters.

A. A PIR Sandwich Panel is ideal for projects requiring superior safety. Thanks to its PIR Core, it performs as a Fire Resistant with low smoke emission and high fire-retardant properties.

A. Fire Retardant Panels provide safety in fire-sensitive zones by resisting ignition and reducing flame spread. A PIR PUF Panel is often chosen where Fire Resistant Panels are required by regulations.

A. The PIR Core creates highly cross-linked molecular bonds, which resist high temperatures (up to ~200°C). This gives PIR Core Panels superior performance in fire scenarios compared to regular PUR foam panels.

A. Yes, PUR Panels are widely used in cold rooms and refrigeration facilities because their insulation properties help maintain controlled temperatures efficiently.

A. Fire Retardant Wall Panels, usually made with a PIR Core, are used in data centers, pharma clean rooms, food processing plants, and kitchens where fire safety is critical.

A. A PUR Sandwich Panel is cost-effective, easy to install, provides excellent insulation, and is versatile enough for multiple uses, including wall cladding, roofing, and prefabricated structures.

A. Yes, a PIR Panel or Fire Retardant Panel is highly suitable for oil & gas facilities because it offers both insulation and fire safety in high-risk environments.

A. Industries like pharmaceuticals, IT/data centers, food processing, and commercial kitchens often use PIR Sandwich Panels because of their compliance with fire safety regulations and superior insulation.

Conclusion

When it comes to modern construction, both Normal PUF Panels (PUR-based) and Fire Retardant PUF Panels (PIR-based) play a vital role. Each option is designed with unique advantages that make it the perfect fit for different applications. A PUR Panel provides cost-effective thermal insulation and is highly reliable for general structures. On the other hand, a PIR PUF Panel built with a PIR Core, offers superior fire safety, making it the preferred choice where a Fire Retardant Panel is required.

Both Solutions Have Their Strengths

- PUR Panels → Ideal for warehouses, cold rooms, prefabricated shelters, and wall cladding where affordability and insulation are key.

- PIR Panels → Recommended for data centers, pharma clean rooms, food processing units, and high-risk zones where Fire Resistant Panels and compliance are critical.

Instead of seeing one as better than the other, it’s best to see them as complementary solutions—each serving a specific purpose in the construction ecosystem.

At Technopuff Solutions, we understand that every project has unique needs. Whether you require a PUR Panel for energy-efficient insulation or a PIR Sandwich Panel for advanced safety, our team is here to guide you. From helping you select between a Normal PUF Panel or a Fire Resistant Panel, to providing detailed cost estimations and custom solutions, we ensure you make the right choice for your project.

Let’s Build Smarter Together

Choosing between PUR PUF Panels and PIR PUF Panels doesn’t have to be complicated. Connect us today for professional advice, product recommendations, and cost-effective solutions tailored to your requirements.

To know more about our range of PUF panels, products, and services, feel free to visit our Homepage.