PUF Panel Banana Ripening Chamber

Bananas are more than just a staple fruit; they represent one of the world’s most significant agricultural commodities. The journey of bananas from farms to consumers is complex and requires meticulous handling to ensure that the fruit remains in peak condition. This necessity underscores the importance of banana ripening chambers in the global supply chain. These specialized facilities are designed to mimic natural ripening conditions, making them crucial for maintaining the quality and longevity of bananas during distribution.

At the heart of this process is the banana ripening chamber, a technological innovation that has transformed how this beloved fruit is brought to market. These chambers provide a controlled environment where bananas can ripen uniformly, reducing spoilage and enhancing flavour. The controlled conditions within a banana ripening room ensure that regardless of external weather conditions or delays in transportation, bananas arrive at their destination ripe and ready for consumption.

The role of PUF (Polyurethane Foam) panels in constructing these chambers cannot be overstated. The banana ripening chamber design incorporates these panels due to their exceptional insulation properties, which are crucial to maintain the specific temperature and humidity required for optimal ripening. PUF panels help in stabilizing internal conditions, leading to energy efficiency and cost-effectiveness in the banana ripening plant operations.

Furthermore, the banana ripening chamber process leverages the insulation capabilities of PUF panels to create an ideal ripening scenario. This setup not only ensures the quality and taste of the bananas but also extends their market life, providing consumers with fresher produce. The integration of these panels into the chamber design represents a significant advancement in the banana supply chain, highlighting the intersection of agriculture and innovative material technology.

As we delve deeper into the specifics of how bananas are brought from the tree to the table, the crucial role of banana ripening chambers equipped with PUF panels becomes increasingly clear. These chambers are not just about keeping bananas yellow; they are a critical component in a complex logistical ballet that ensures this tropical fruit can be enjoyed worldwide.

Understanding Banana Ripening Chambers

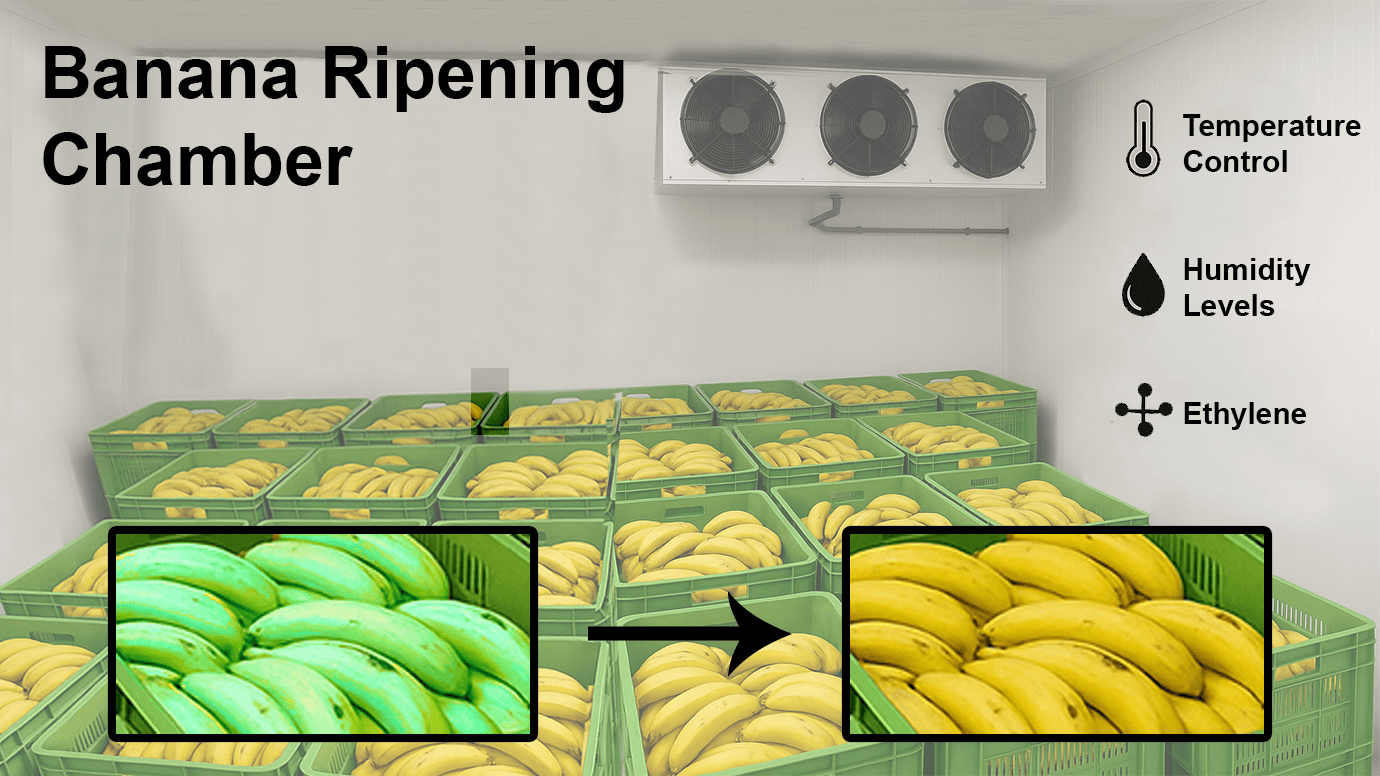

Banana ripening chambers are specialized facilities that are critical to the post-harvest process of bananas. Essentially, a banana chamber is designed to control the environmental conditions that influence the ripening of bananas, thereby ensuring that they reach consumers in the best possible state of freshness and flavour. The design and operation of these chambers are central to the activities of any banana ripening plant.

Overview of Banana Ripening Process and Key Components

The primary function of these chambers is to simulate the natural conditions that trigger bananas to ripen evenly and predictably. The banana ripening chamber design incorporates systems that can carefully control temperature, humidity, and ethylene levels.

- Ethylene: It is a natural plant hormone that plays an important role in the ripening process. In the controlled environment of a banana ripening room, ethylene gas is introduced to stimulate the ripening process. This artificial induction of the ripening process is a key aspect of the banana ripening chamber process.

- Temperature control: It is another crucial factor. Banana ripening chambers maintain a consistent temperature that is typically between 14°C to 18°C, which is optimal for bananas. This temperature range helps in accelerating the ripening process without causing the bananas to deteriorate due to excessive heat or cold.

- Humidity levels: It is also meticulously managed in a banana chamber. The ideal humidity range is between 90% to 95%. This level of humidity prevents the bananas from losing moisture and becoming dry, while also discouraging the growth of mold and other pathogens. Managing humidity is crucial for maintaining the structural integrity and weight of the fruit, which are important for both quality and commercial value.

In summary, banana ripening chambers are sophisticated components of the banana ripening plant, designed to control the precise conditions of ethylene concentration, temperature, and humidity. This controlled environment not only ensures that bananas ripen uniformly but also optimizes their taste, texture, and shelf life, making them ready for sale and consumption at their peak condition. The careful balance of these factors in the banana ripening chamber process is what makes the modern distribution of this popular fruit possible.

The Role of PUF Panels in Banana Ripening Chambers

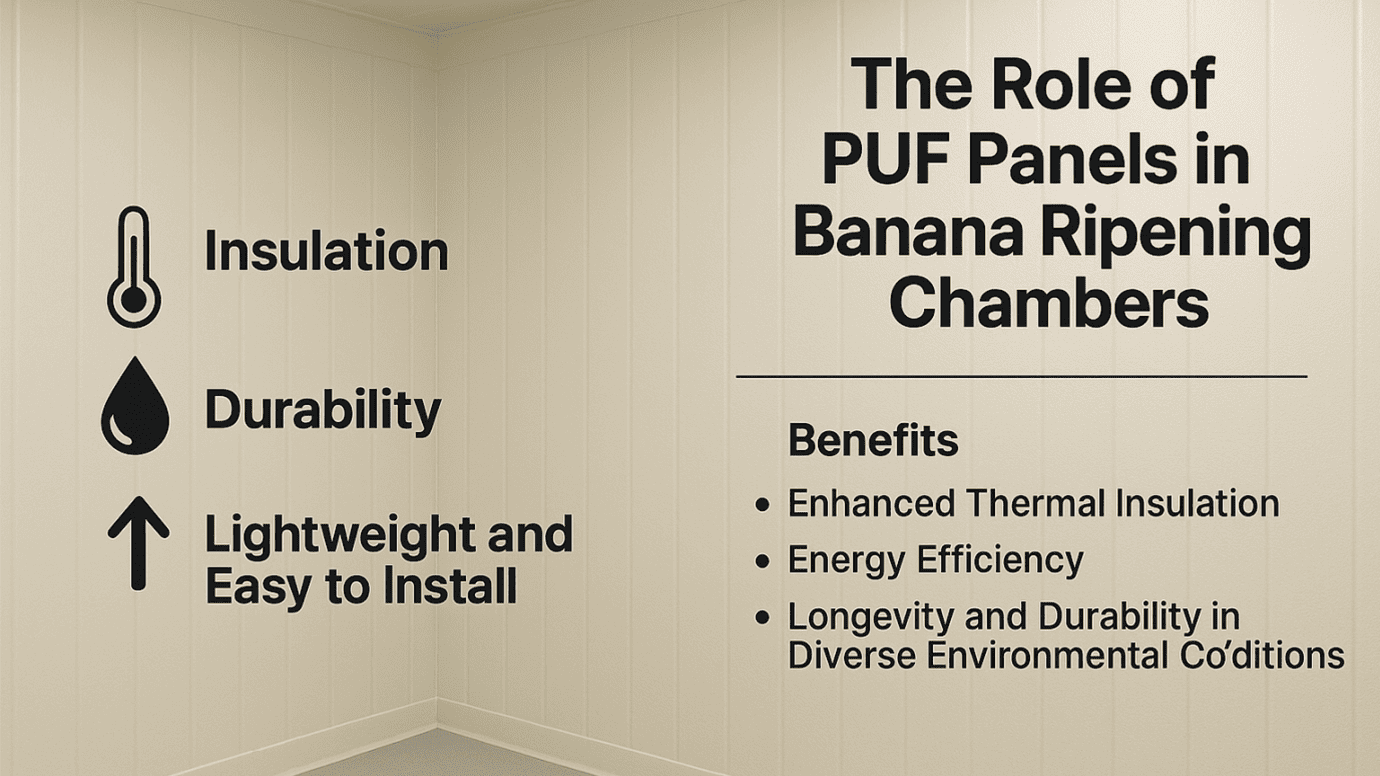

PUF (Polyurethane Foam) panels are increasingly becoming a critical component in the construction of banana ripening chambers. Their unique properties and benefits play a significant role in enhancing the effectiveness of these specialized facilities.

Properties of PUF Panels

- Insulation: PUF panels are known for their excellent thermal insulation properties, which is crucial in maintaining the required temperature within a banana ripening room.

- Durability: These panels are highly durable, resistant to moisture and decay, which makes them perfect for use in environments that require stringent control over humidity and temperature.

- Lightweight and Easy to Install: PUF panels are lightweight, making them easy to transport and install, which speeds up the construction of banana ripening chambers.

Benefits of Using PUF Panels in Banana Ripening Chambers

- Enhanced Thermal Insulation: The superior insulation properties of PUF panels allow for better control of the internal conditions of banana ripening chambers. This precise temperature control is essential for the proper ripening of bananas, ensuring that they do not ripen too quickly or slowly.

- Energy Efficiency: Due to their excellent insulation capabilities, PUF panels help reduce the energy needed to maintain optimal temperatures and humidity levels in a banana ripening plant. This reduction in energy consumption not only lowers operating costs but also enhances the environmental sustainability of the operation.

- Longevity and Durability in Diverse Environmental Conditions: PUF panels are capable of withstanding a range of environmental conditions without degrading in quality or performance. Their durability ensures that the banana ripening chamber design remains effective over many years, reducing the need for frequent repairs or replacements.

Impact on the Banana Ripening Chamber Process

- By integrating PUF panels into the banana ripening chamber design, facilities can achieve a more uniform ripening process due to the stable internal environment. This leads to higher quality bananas that meet consumer expectations for taste and texture.

- The consistency provided by the effective use of PUF panels in banana chambers ensures that each batch of bananas can be ripened to the exact standards required, minimizing waste and maximizing efficiency.

PUF panels are indispensable in modern banana ripening chambers. Their insulation efficiency, durability, and energy-saving properties make them an excellent choice for businesses looking to optimize their banana ripening chamber process and ensure the delivery of high-quality fruit to the market.

The Construction of Banana Ripening Chambers with PUF Panels

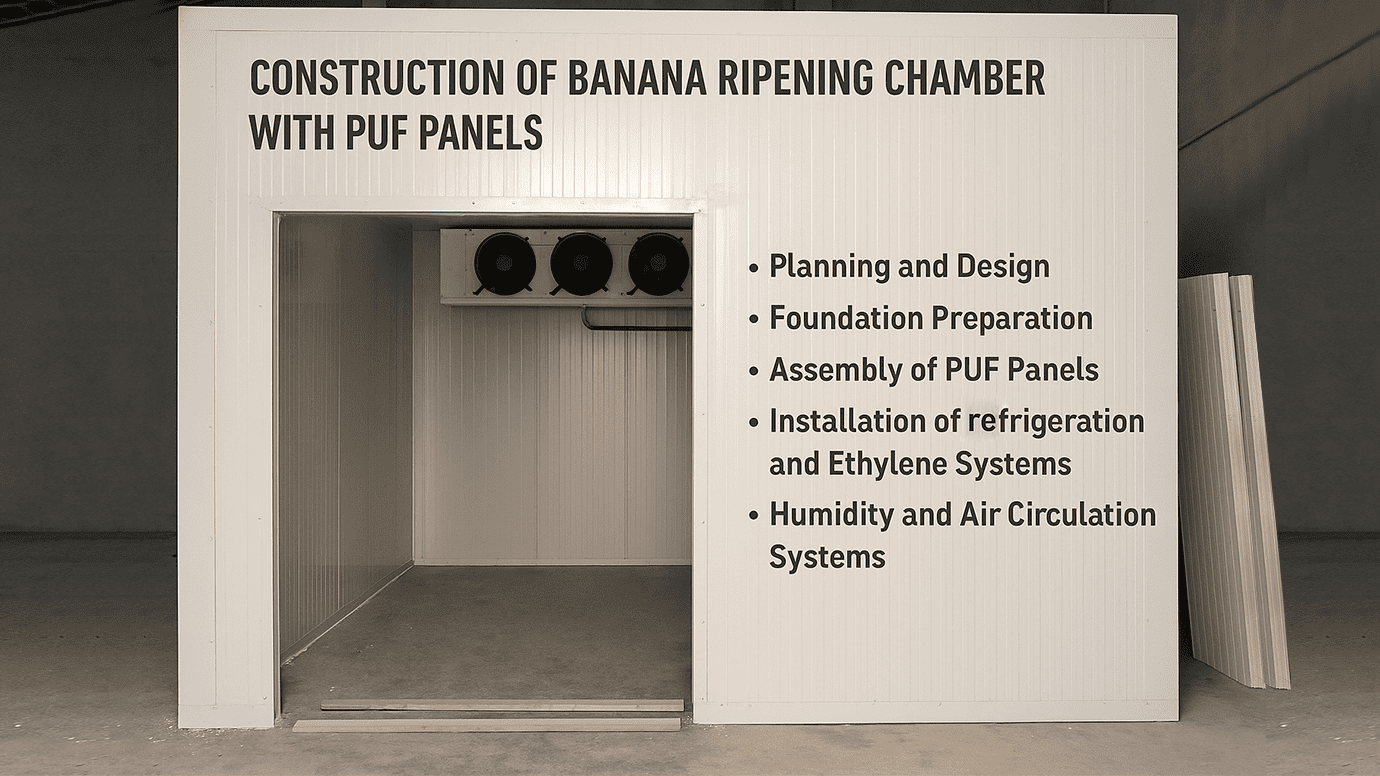

The construction of banana ripening chambers using PUF (Polyurethane Foam) panels involves meticulous planning and precise execution to ensure optimal ripening conditions for bananas. Here are steps on how banana ripening chambers are constructed, along with a discussion on the key design considerations and technical specifications.

Steps to Construct PUF Panel Banana Ripening Chamber

Planning and Design:

- The initial step in the construction of banana ripening chambers involves detailed planning to determine the size and capacity of the banana ripening room. Factors such as the volume of bananas to be ripened and the space available at the banana ripening plant are considered.

- Detailed banana ripening chamber design plans are drawn up, specifying the layout, ventilation systems, ethylene gas distribution points, and insulation requirements.

Foundation Preparation:

- A solid foundation is prepared to support the weight of the banana chamber and its contents. This may involve levelling the ground and laying a concrete base to ensure stability and structural integrity.

Assembly of PUF Panels:

- PUF panels are delivered to the site, pre-cut to fit the chamber's design specifications.

- The panels are assembled to form the walls, ceiling, and floor of banana ripening chambers. Special attention is given to ensure that the panels fit tightly together to prevent heat loss and maintain consistent internal conditions.

Installation of Refrigeration and Ethylene Systems:

- Refrigeration units are installed to control the temperature within the banana ripening room. These units are designed to maintain the precise temperatures needed for optimal banana ripening.

- Ethylene generators and distribution systems are also installed, allowing for controlled release of ethylene, which is crucial for triggering the ripening process in banana ripening chambers.

Humidity and Air Circulation Systems:

- Humidity control systems are installed to maintain the required humidity levels, which are critical to prevent dehydration of the bananas.

- Proper air circulation systems are set up to ensure even distribution of ethylene gas and maintain uniform temperature and humidity throughout the banana ripening chambers.

Final Testing and Calibration:

- Once construction is completed, the banana chamber is tested to make sure that all systems are functioning correctly. Temperature, humidity, and ethylene levels are monitored and adjusted as necessary to meet the specific ripening requirements.

Design Considerations and Technical Specifications for PUF Panel Banana Ripening Chambers

Thermal Insulation

One of the primary considerations in the design of banana ripening chambers is the insulation capability of the PUF panels. The panels must provide sufficient thermal resistance to maintain stable temperatures with minimal energy consumption.

Durability

The PUF panels used must be of high quality to withstand the humid and ethylene-rich environment of banana ripening chambers without deteriorating.

Energy Efficiency

The design should incorporate energy-efficient technologies to reduce the operational costs of the banana ripening plant. This includes high-efficiency refrigeration systems and LED lighting.

Ethylene and Ventilation Control

The banana chamber must be equipped with precise control systems for ethylene gas distribution and effective ventilation to ensure even ripening of all bananas.

Constructing banana ripening chambers with PUF panels requires careful attention to detail and adherence to technical specifications to achieve the desired outcomes in banana ripening. The benefits of using PUF panels, such as superior insulation and durability, make them an ideal choice for these specialized applications.

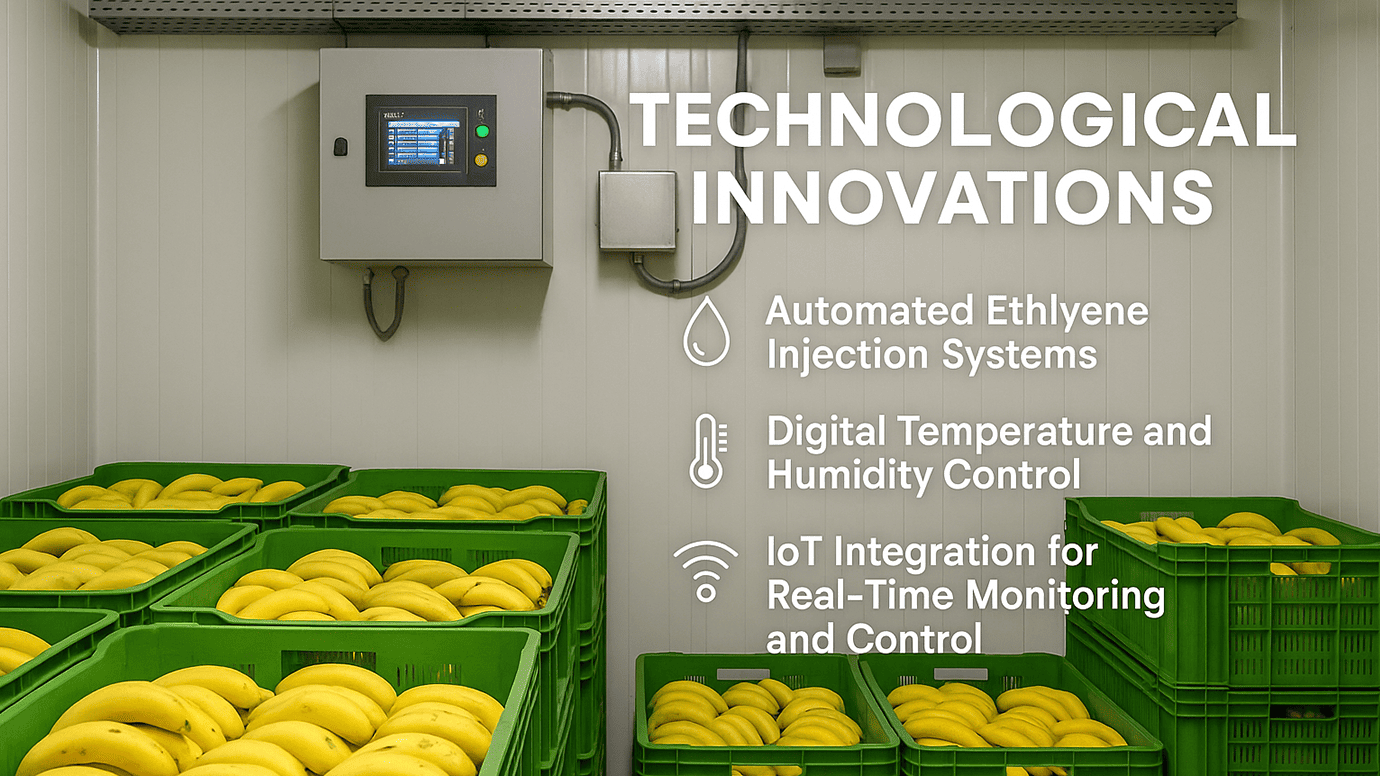

Technological Innovations in Banana Ripening Chambers

The advancement of technology has greatly enhanced the capabilities and efficiency of banana ripening chambers. Modern banana chambers now incorporate a range of sophisticated features that automate and optimize the ripening process. These innovations not only improve the quality and consistency of ripened bananas but also contribute to the operational efficiency of the banana ripening plant.

Automated Ethylene Injection Systems

- Role and Importance: Ethylene is a critical component in the banana ripening process, acting as the natural hormone that triggers ripening. Automated ethylene injection systems in banana ripening chambers precisely control the amount and timing of ethylene released into the chamber, ensuring uniform ripening across all bananas.

- Technology in Action: These systems are equipped with sensors and timers that monitor the internal environment of the banana ripening room and adjust ethylene levels based on specific ripening stages. This automation reduces the need for manual intervention, making the banana ripening chamber process more consistent and less labour-intensive.

Digital Temperature and Humidity Control

- Advanced Controls: Maintaining the correct temperature and humidity within banana ripening chambers is crucial for optimal ripening. Digital temperature and humidity control systems provide precise regulation of these environmental factors, adapting in real-time to changes in chamber conditions.

- Integration and Benefits: The integration of digital controls in the banana ripening chamber design allows for finer adjustments, which are critical for maintaining the quality and increasing the shelf life of bananas. These systems can automatically adjust settings to compensate for external temperature fluctuations or changes in banana chamber load capacity.

IoT Integration for Real-Time Monitoring and Control

- IoT Capabilities: The Internet of Things (IoT) represents a significant innovation in banana ripening chambers. IoT devices can connect various components of the banana ripening room to a central system that monitors and controls the ripening process remotely.

- Implementation and Advantages: Sensors connected via IoT can track everything from gas levels to temperature and humidity, providing a comprehensive view of the ripening environment. Data collected by these sensors is analyzed to optimize chamber settings continuously. IoT integration enables operators to remotely monitor and adjust chamber conditions, leading to enhanced operational efficiency, reduced risk of human error, and improved ability to respond to issues in real-time.

These technological innovations represent a leap forward in the design and functionality of banana ripening chambers. By integrating automated ethylene injection systems, digital temperature and humidity controls, and IoT capabilities, banana ripening plants can achieve higher levels of precision, efficiency, and product quality. This makes the modern banana ripening chambers not just a necessity for ensuring peak ripeness but also a testament to the power of technology in transforming agricultural practices.

The Economic and Environmental Impact of Using PUF Panels for Banana Ripening Chambers

The integration of PUF panels into banana ripening chambers has significant economic and environmental implications. By analyzing the cost-effectiveness and sustainability of these materials in banana ripening chamber design, we can understand their broader impact on the banana ripening process.

Economic Impact of Using PUF Panels for Banana Ripening Chambers

- Cost-Effectiveness: PUF panels, known for their superior insulation properties, provide an economically viable option for constructing banana ripening chambers. Their high thermal resistance helps maintain the required temperature and humidity levels with less energy consumption, resulting in lower operational costs for banana ripening plants.

- Long-Term Savings: The durability and longevity of PUF panels also mean that banana chambers require less frequent repairs and maintenance. This reduces the long-term capital expenditure for businesses involved in banana ripening, making PUF panels a cost-effective choice over other materials like polystyrene or fiberglass.

- ROI Analysis: Incorporating PUF panels in the banana ripening chamber design leads to a faster return on investment due to energy savings and reduced maintenance costs. Facilities can recover installation costs quicker, making it a financially sound investment for modern banana ripening plants.

Environmental Impact of PUF Panels for Banana Chambers

- Energy Efficiency: PUF panels help in significantly lowering energy use in banana ripening chambers due to their high insulation efficiency. By maintaining optimal ripening conditions with less energy, these chambers contribute to a reduced carbon footprint, which is crucial in today’s energy-conscious world.

- Reduction in Waste: The longevity of PUF panels means that the materials need to be replaced less frequently, leading to a decrease in waste generated from the construction and refurbishment of banana ripening rooms. Furthermore, the effective ripening process reduces spoilage rates of bananas, thus minimizing organic waste.

- Sustainability Practices: The use of PUF panels supports sustainability in agricultural practices by enhancing the overall energy efficiency of the banana ripening chamber process. This alignment with eco-friendly practices not only helps banana ripening plants meet regulatory requirements but also appeals to a consumer base that values environmental responsibility.

The adoption of PUF panels in banana ripening chamber design represents a strategic approach that benefits both the economy and the environment. This integration not only boosts the operational efficiency of banana ripening chambers but also aligns with global efforts to enhance sustainability in agricultural processing. As the industry continues to evolve, the economic and environmental impacts of such innovations will play a critical role in shaping the future of banana ripening technologies.

FAQs

A. Banana ripening chambers regulate the release of ethylene gas, which triggers the ripening process, while maintaining precise temperature and humidity levels to make sure uniform ripening across all bananas.

A. PUF panels provide superior insulation, which enhances thermal efficiency, reduces energy consumption, and ensures durability under diverse environmental conditions in banana ripening rooms.

A. Precise temperature control in banana ripening chambers is crucial for managing the ripening speed and quality of bananas, preventing them from ripening too quickly or slowly.

A. Ethylene is a naturally occurring plant hormone used in banana ripening chambers to initiate and accelerate the ripening process of bananas.

A. Yes, the banana ripening chamber design is critical as it involves integrating systems for ethylene distribution, temperature control, and humidity management to create an optimal ripening environment.

A. When constructing a banana ripening chamber, factors to consider include the selection of high-quality PUF panels, the integration of efficient refrigeration and ethylene systems, and ensuring proper air circulation.

A. PUF panels reduce the need for frequent heating or cooling adjustments, thus lowering energy costs and making the banana ripening chamber process more cost-effective.

A. For expert advice on initiating a banana ripening chamber project using PUF panels, contacting companies like Technopuff Solutions, which specialize in advanced agricultural solutions, is recommended.

Conclusion

Throughout our discussion on the utilization of PUF panels within banana ripening chambers, we’ve delved into their critical role in enhancing both operational efficiency and sustainability in agricultural settings. These chambers, pivotal for regulating the ripening process, leverage advanced technology to manage internal conditions meticulously—controlling temperature, humidity, and ethylene levels to ensure bananas ripen uniformly and maintain peak quality.

The advantages of PUF panels are clear; their superior insulation, durability, and energy efficiency make them an ideal choice for constructing banana ripening rooms. These attributes contribute significantly to the sustainability and economic viability of banana ripening plants, reducing both operational costs and environmental impact. The integration of innovative features like automated ethylene injection systems, digital controls, and IoT connectivity further streamlines the banana ripening chamber process, enhancing precision and reducing the need for manual intervention.

Looking ahead, the potential applications of PUF panels extend well beyond banana ripening chambers. The agricultural sector can leverage these panels in diverse applications such as cold storage rooms and other ripening chambers, suggesting a broad future for PUF panels in enhancing food processing and storage across the industry. This expansion is likely to drive further advancements in agricultural infrastructure, promoting efficiency and sustainability on a larger scale.

If you are considering to initiate a banana ripening chamber project or wish to explore how PUF panels can enhance your agricultural operations, Technopuff Solutions is ready to assist. We encourage you to contact Technopuff Solutions for detailed insights into the benefits of our PUF panels. By partnering with us, you will not only meet industry standards but also contribute to a more sustainable and efficient agricultural practice. Start your journey towards a more profitable and environmentally friendly operation with Technopuff Solutions today.

In essence, PUF panels represent a transformative advancement in the design and functionality of banana ripening chambers. As we look to the future, their role in promoting sustainability and efficiency in agriculture is set to expand, heralding a new era of innovation in the sector.

For more details about PUF Panels and other structures that can be constructed from it, go to our PUF Panels page.