PUF Panel Doors Manufacturer

Welcome to the innovative world of PUF panel doors, a leading solution in the world of modern construction and industrial applications. These doors, crafted using advanced PUF (Polyurethane Foam) technology, represent a significant advancement in building technology, offering superior insulation and robust performance in various environments.

PUF panel doors are not just a product; they are a crucial component in enhancing the energy efficiency and comfort of buildings. The core material, polyurethane foam, is known for its exceptional thermal insulation properties, making these doors ideal for maintaining temperature control in buildings ranging from residential homes to industrial facilities.

The importance of these doors in modern construction cannot be overstated. As industries and construction developers continually seek sustainable and cost-effective solutions, PUF panel doors serve as an essential element in achieving these goals. They are particularly beneficial in modular homes, where efficiency and quick assembly are prized.

Highlighting the expertise in this field is Technopuff Solutions, a name synonymous with quality and innovation. As one of the leading PUF doors manufacturers, Technopuff Solutions has set benchmarks in the industry with their state-of-the-art design and manufacturing techniques. Their PUF panel doors are customized to meet the diverse needs of their clients, ensuring that each door is not only functional but also aesthetically pleasing.

Whether you’re constructing a new home, upgrading your office space, or setting up a specialized industrial plant, Technopuff Solutions’ PUF panel doors for modular homes and other applications promise performance, durability, and energy savings. Dive deeper into our blog to discover how these advanced doors can transform your projects and meet the stringent demands of modern construction requirements.

What are PUF Panel Doors?

PUF panel doors, an integral component of modern architectural design and construction, are engineered for exceptional performance in various environments, from residential to commercial settings. These doors are made using PUF panels, which consist of polyurethane foam sandwiched between two layers of structural material, such as metal, wood, or composite facings. This design ensures that the doors are not only sturdy but also provide superior insulation properties.

The basic structure of a PUF panel door involves a core of dense, lightweight polyurethane foam. This foam core is encapsulated by durable coverings that can withstand harsh environmental conditions and frequent usage, making PUF doors especially suited for both external and internal applications. PUF panels are celebrated for their thermal insulation capabilities, which stem from the high R-value of polyurethane foam, ensuring that these doors significantly enhance the energy efficiency of any structure.

Advantages over other Materials

- When compared with traditional door types, such as wooden doors or plain metal doors, PUF panel doors offer several distinct advantages. Traditional doors often require additional insulation materials to achieve the same level of thermal and acoustic isolation that a PUF door provides inherently.

- Additionally, due to their robust construction, PUF panel doors are typically more resistant to warping, cracking, and other forms of environmental wear and tear. This makes them an ideal choice for areas that experience extreme weather conditions or require high levels of cleanliness and hygiene, such as in modular homes or industrial facilities.

PUF doors manufacturers like Technopuff Solutions have further refined the utility of these doors by offering PUF panel flat doors that combine sleek aesthetics with functionality. These doors are particularly popular in the construction of PUF Panel doors for modular homes, where efficiency, durability, and a clean, modern look are paramount.

In conclusion, PUF panel doors represent a superior choice for those looking to enhance the energy efficiency, security, and aesthetic appeal of their buildings. With advantages over traditional door types in almost every aspect, they are increasingly becoming the go-to option for savvy builders and architects in the industry.

Key Benefits of PUF Panel Doors

PUF panel doors offer a number of benefits that make them a preferred choice in various construction and industrial applications. Their unique construction and material properties allow for enhanced performance in several key areas:

Thermal Insulation

One of the standout features of PUF doors is their exceptional thermal insulation. The polyurethane foam core within these doors acts as an excellent thermal barrier, effectively maintaining temperature control within any space. This makes PUF panel doors particularly suitable for environments like modular homes, where maintaining a consistent internal temperature can significantly enhance comfort and reduce energy consumption. The insulation properties ensure that heat stays out during the summer and remains inside during the winter, creating a more energy-efficient living or working space.

Acoustic Insulation

In addition to their thermal capabilities, PUF panel doors also provide substantial acoustic insulation. This feature is crucial for locations that require sound barriers to minimize noise pollution, such as recording studios, schools, hospitals, and high-traffic areas within commercial buildings. The density and thickness of the polyurethane foam effectively block and absorb sound waves, ensuring a quieter and more serene environment.

Energy Efficiency

The energy efficiency of PUF panel doors is directly tied to their insulation properties. By minimizing the loss of heat or cool air, these doors help to reduce the reliance on heating and cooling systems, which in turn lowers energy costs significantly. This efficiency is a key reason why PUF doors manufacturers like Technopuff Solutions recommend these doors for modular homes and energy-conscious constructions, aiming to meet stricter energy regulations and reduce environmental impact.

Durability and Strength

PUF panel doors are renowned for their durability and strength. The robust construction, involving a protective layering around a foam core, allows these doors to withstand harsh environmental conditions, including heavy winds, rain, and drastic temperature changes without warping or deteriorating. This makes them an ideal choice for both external and internal doors, providing long-lasting performance with minimal maintenance requirements.

Fire Resistance

Fire safety is a critical consideration in any building's design, and PUF panel doors contribute positively in this area. The materials used in the manufacture of these doors can be treated with fire-retardant chemicals that help to slow the spread of fire and provide additional evacuation time during an emergency. This feature is particularly valued in commercial buildings, industrial settings, and residential areas where fire safety regulations are stringent.

Overall, the benefits of PUF panel doors extend beyond simple functionality. They are a cost-effective, durable, and environmentally friendly option that meets the diverse needs of modern construction. Whether it’s a PUF panel flat door for a sleek, contemporary look or a standard PUF door for rigorous industrial use, these doors offer a comprehensive solution for enhancing building performance and occupant comfort.

Applications of PUF Panel Doors

The versatility of PUF panel doors makes them suitable for a broad range of applications across various sectors. Their unique properties allow them to fulfil the specific needs of industrial, commercial, residential, and specialized environments.

Industrial Uses

In industrial settings, PUF panel doors are essential for maintaining optimal conditions within cold storages, warehouses, and manufacturing facilities. These doors help in stabilizing internal temperatures, vital for the preservation of perishable goods in cold storages. In warehouses and manufacturing facilities, they contribute to energy conservation and enhance security, providing a controlled environment that can help to increase the lifespan of stored products and machinery.

Commercial Applications

For commercial buildings, like office buildings, hotels, and hospitals, PUF panel doors offer enhanced insulation properties that contribute to a comfortable indoor climate, essential for the well-being of occupants and efficient building management. In hotels, these doors ensure guest comfort by minimizing noise and regulating temperatures. In hospitals, they are vital in preventing the spread of contaminants, maintaining sterile environments in areas like operating rooms and intensive care units.

Residential Use

In residential areas, particularly in modular homes, PUF panel doors are employed as garage doors and exterior doors in harsh climates. They give excellent thermal insulation, reducing heating and cooling costs while ensuring that homes remain comfortable regardless of external weather conditions. Their strong construction also offers increased security, an essential consideration for residential properties.

Specialized Applications

PUF doors are particularly advantageous in specialized applications such as pharmaceuticals, food processing units, clean rooms, data centers, and facilities with soundproofing requirements. In pharmaceuticals and food processing units, maintaining a contamination-free environment is critical, and PUF panel doors facilitate this by offering an airtight seal. Clean rooms benefit from the minimal particle emission of PUF doors, while data centers utilize them for their ability to maintain steady temperatures, crucial for protecting sensitive electronic equipment. Additionally, in environments requiring soundproofing, such as recording studios or research facilities, these doors help in creating a quiet and controlled space.

Across all these applications, PUF panel doors stand out for their ability to enhance functional efficiency and safety. Their broad usage spectrum showcases their adaptability and effectiveness in fulfilling the diverse requirements of modern architectural and industrial landscapes. Whether it’s in a high-end PUF panel flat door for aesthetic appeal in commercial settings or a robust PUF door for security in industrial sites, PUF doors manufacturers like Technopuff Solutions ensure that their products fulfil the highest standards of quality and performance.

Below are the dedicated blogs of some PUF Panel doors used in various industries provided by us:

The Manufacturing Process of PUF Panel Doors

The manufacturing process of PUF panel doors is a sophisticated procedure that combines advanced technology and stringent quality standards to produce doors that meet the high expectations of today’s industrial, commercial, and residential markets. Here’s a step-by-step look at how PUF doors are made, highlighting the meticulous attention to detail at every stage.

Design and Engineering

The process begins with the detailed design and engineering phase, where the specifications of the PUF door are defined. This includes determining the dimensions, thermal requirements, fire resistance needs, and any special features required for the door’s intended application. CAD (Computer-Aided Design) software is typically used to create precise blueprints that will guide the production process.

Material Preparation

The core materials for PUF panel doors, primarily the polyurethane foam and the outer skins (which can be made of steel, aluminium, or other durable materials), are prepared. The outer materials are cut to size, and any necessary hardware components, such as hinges, handles, and locking mechanisms, are gathered.

Foam Injection

In this critical stage, the polyurethane foam is injected between the prepared outer skins. This is done using a high-precision, automated foam-injection process that ensures the foam is evenly distributed throughout the panel. The chemical components of the polyurethane are mixed and injected in a controlled environment to ensure optimal expansion and curing, which is vital for achieving the desired insulation properties and structural integrity.

Curing and Setting

After injection, the PUF panel is allowed to cure in a temperature-controlled setting. This step is crucial as it allows the polyurethane foam to fully expand and harden, bonding with the outer skins to form a solid, insulated panel. The curing time can differ on the basis of the type of polyurethane used and the thickness of the door.

Trimming and Finishing

Once cured, the doors are moved to the trimming area where any excess material from the foaming process is removed, and the doors are cut to their final dimensions. Following this, additional components like windows, louvers, or specific finishes are added. The doors are then sanded, cleaned, and prepared for painting or coating, based on customer specifications.

Quality Control and Testing

Every PUF door undergoes rigorous quality control checks and testing to make sure it meets the required specifications and quality standards. Tests for thermal performance, structural integrity, fire resistance, and durability are conducted. This ensures that every door performs reliably in its intended environment.

Packaging and Dispatch

Finally, the doors are carefully packaged to prevent any damage during transit and are then dispatched to the customer or construction site. Special packaging materials may be used to protect the doors’ finish and ensure that they arrive in pristine condition.

As a leading PUF doors manufacturer, we pride ourselves on our commitment to using state-of-the-art technology and following the highest quality standards throughout the manufacturing process. This meticulous approach ensures that our PUF panel doors are not only highly functional but also durable and reliable, providing our clients with the best possible products on the market.

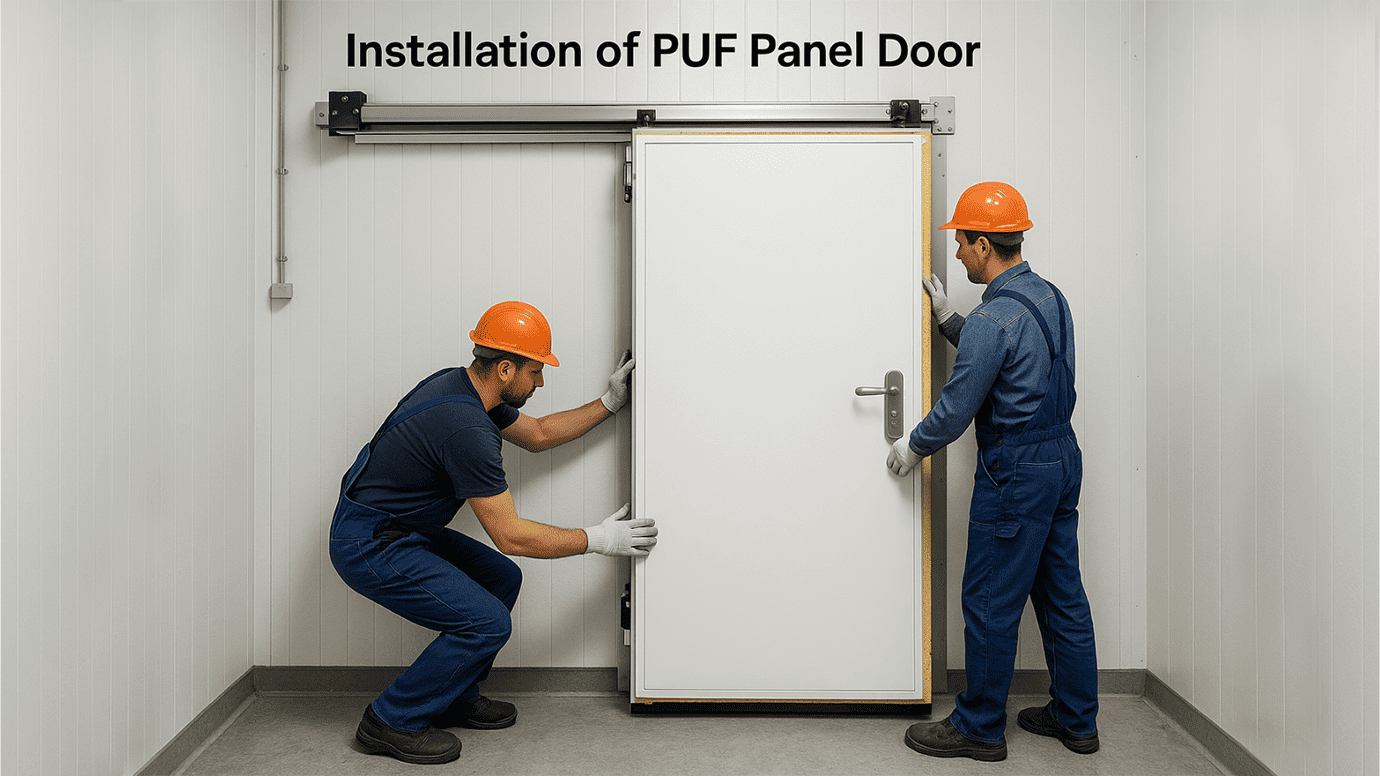

Customization and Installation of PUF Panel Doors

PUF panel doors are highly versatile, not only in their application but also in their customization options, making them a favored choice for a wide range of building projects. As leading PUF doors manufacturers, Technopuff Solutions provide extensive customization capabilities to meet specific needs, along with a streamlined installation process and robust after-sales support.

Customization Options

- Sizes: One of the primary advantages of PUF panel doors is their availability in various sizes. Whether you need a standard size for residential use or a custom size for a large industrial project, doors can be manufactured to exact dimensions. This flexibility ensures that they fit perfectly into any opening, providing optimal insulation and functionality.

- Finishes: We provide a variety of finishes to suit different aesthetic and functional requirements. Options include but are not limited to, powder-coated colors, wood grain laminates, and stainless steel finishes. These choices allow the doors to blend seamlessly with the building’s exterior or interior design or to stand out as a feature element if desired.

- Hardware: Customization extends to the hardware of the PUF doors as well. Clients can choose from a range of handles, locks, viewing panels, and other hardware options that not only enhance the door’s usability but also its security features.

Installation Process and Guidelines

The installation of PUF panel doors is a critical step that requires precision and expertise. Our installation process includes the following steps:

- Pre-Installation Assessment: Before installation begins, a thorough assessment of the site is conducted. This ensures that the door frame and opening are properly prepared and that any specific conditions or challenges are addressed in advance.

- Frame Setup: The door frame is first installed and secured to the building's structure. This frame is crucial as it supports the entire door system.

- Door Mounting: The PUF panel door is then carefully mounted to the frame. Special attention is given to ensure that the door is perfectly aligned and level.

- Sealing and Finishing: Once the door is mounted, it is sealed around the edges to prevent any air leaks. The final finish is then applied, and additional hardware is installed.

- Operational Testing: After the door is installed, it undergoes operational testing to ensure that it opens and closes smoothly and that all locks and security features function correctly.

After-sales Support and Services

We understand that our responsibility does not end at installation. Our after-sales support and services are designed to make sure that our PUF doors continue to perform optimally over their lifespan. This includes:

- Maintenance Services: Frequent maintenance checks and servicing to ensure the door remains in excellent condition and functions efficiently.

- Warranty Support: We provide a comprehensive warranty for our PUF panel doors, covering any manufacturing defects or issues that may arise.

- Customer Service: Our dedicated customer service team is always available to answer any queries and assist with any issues related to the performance or functionality of the doors.

Technopuff Solutions is committed to provide not just high-quality PUF panel doors but also ensure that every aspect of customization, installation, and after-sales service meets the highest standards of excellence. This comprehensive approach ensures customer satisfaction and the long-term durability and performance of products.

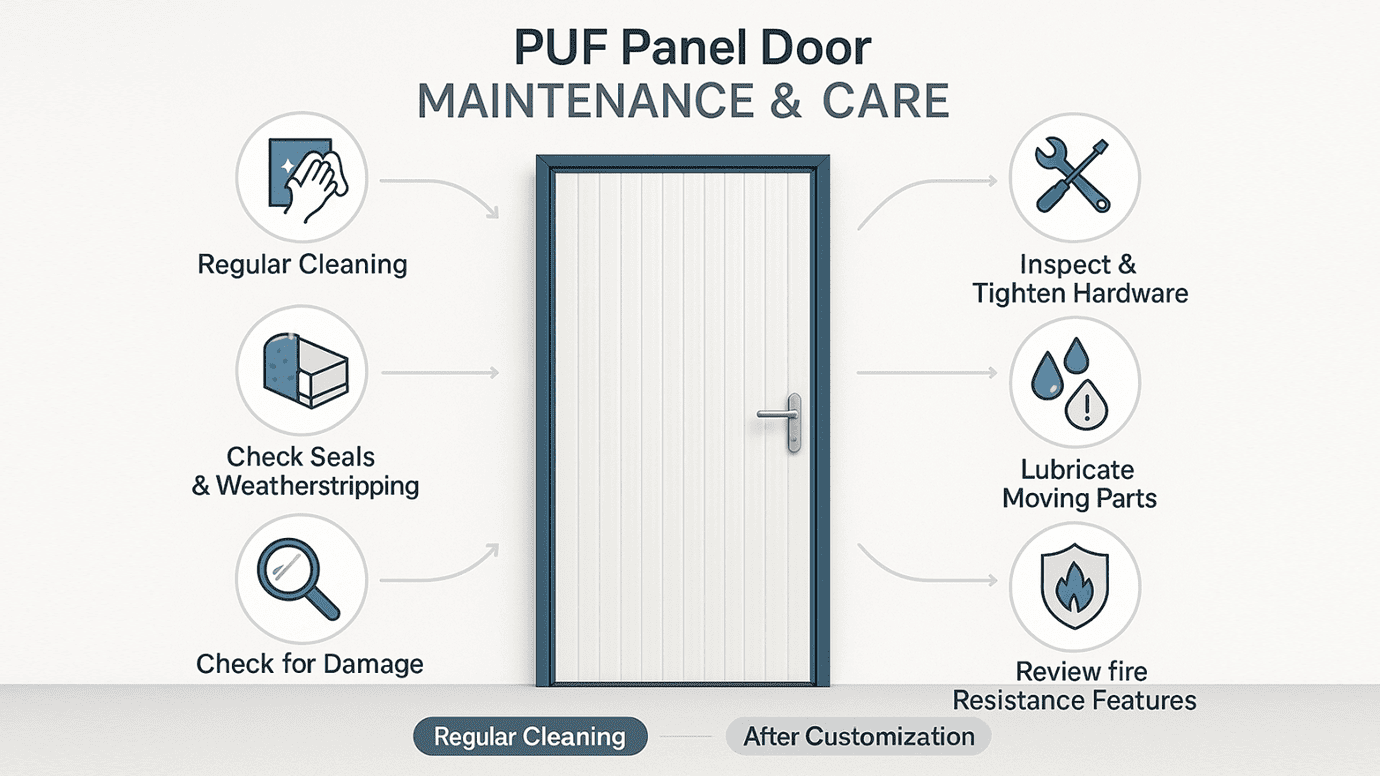

Maintenance and Care of PUF Panel Doors

Proper maintenance and care are crucial for making sure the longevity and functionality of PUF panel doors. These doors are designed to be low maintenance, yet regular attention can help extend their lifespan and maintain their appearance and performance. Here’s a comprehensive guide to maintaining your PUF door, whether it’s a flat door or a specialized PUF panel door for a modular home.

Regular Cleaning

Keeping your PUF panel doors clean is essential. Dust and dirt can accumulate on the surface, which not only affects the door's appearance but can also impair its function over time. Use a soft cloth and a mild detergent to clean the door surfaces gently. Avoid abrasive cleaners or pads that could scratch or damage the finish.

Check Seals and Weatherstripping

The seals and weatherstripping around your PUF door play a critical role in maintaining its insulation properties. Check these regularly for signs of wear or damage and replace them if necessary to make sure that the door continues to provide optimal thermal and acoustic insulation.

Inspect and Tighten Hardware

Over time, the hardware on your door, such as hinges, handles, and locks, may become loose. Regularly check these components and tighten them if needed. This not only ensures the door’s functionality but also enhances security.

Lubricate Moving Parts

To keep the door operating smoothly, lubricate the hinges and any other moving parts periodically. Use a suitable lubricant designed for this purpose to prevent sticking or squeaking.

Check for Damage

Regularly inspect your door for any signs of damage, such as dents, scratches, or warping. Early detection of these issues can prevent more severe problems later on. If damage is noted, consult with a professional for repair or advice to ensure that the integrity of the door is maintained.

Monitor for Moisture

Especially in harsh climates, check for any signs of moisture ingress around your PUF panel door. Moisture can degrade the materials and reduce the door’s insulative properties. Make sure that the door and its surroundings are well-sealed against water penetration.

Review Fire Resistance Features

If your PUF door is equipped with fire resistance features, ensure they are always in operational condition. This may involve checking intumescent seals and other fire-preventive components that are critical in maintaining the door's fire-resistance rating.

By following these routine maintenance tips, you can help ensure that your PUF panel doors continue to function effectively and efficiently for many years.

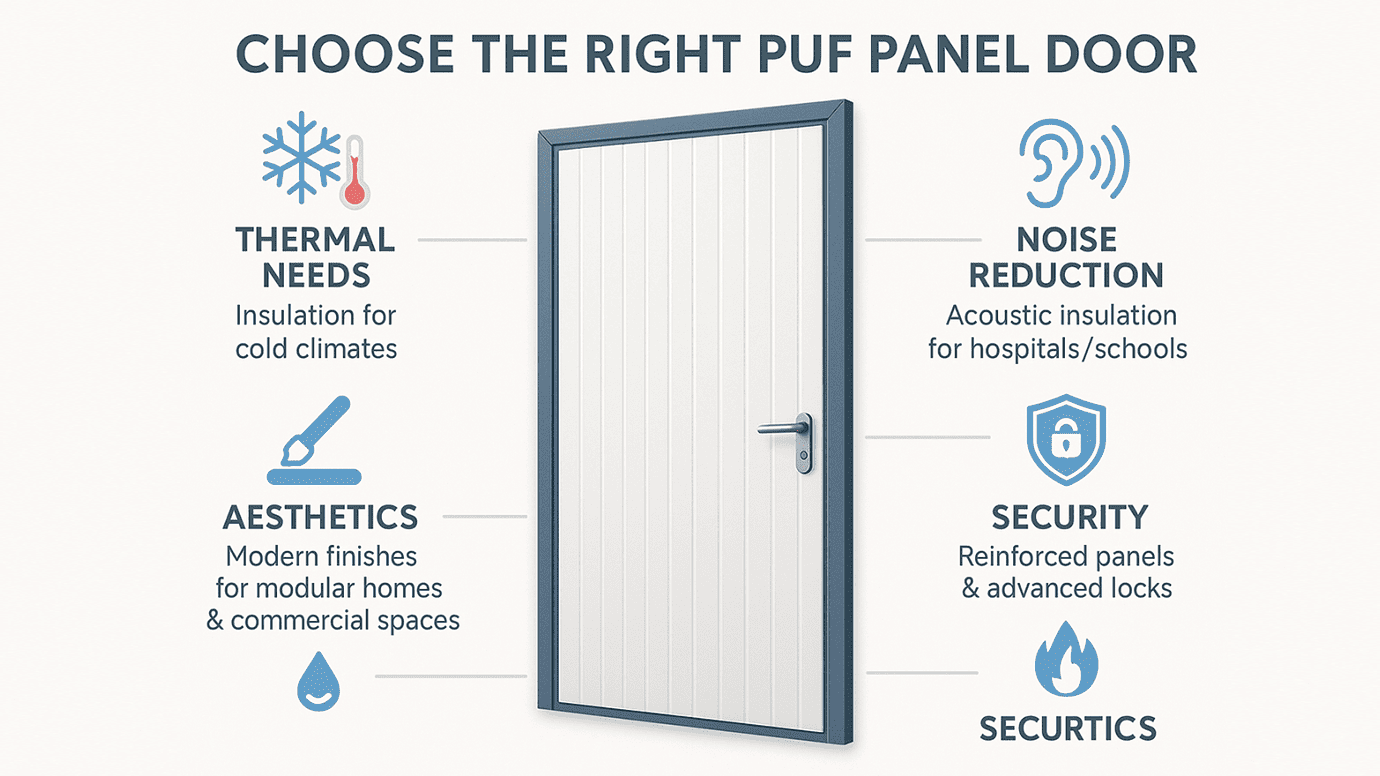

Choosing the Right PUF Panel Door

Selecting the correct PUF panel door is crucial for making sure that it meets the specific needs of your project, whether it’s for a modular home, an industrial facility, or a commercial building. Here are several critical factors to consider when choosing a PUF door, including how to assess its quality and performance, and why sourcing from reputable PUF doors manufacturers like Technopuff Solutions is essential.

Factors to Consider Based on Application

- Thermal Needs: One of the primary advantages of PUF panel doors is their superior insulation properties. Consider the climatic conditions of the installation site and the thermal requirements of the building. For colder climates, doors with higher insulation values will be beneficial in minimizing heat loss and reducing energy costs.

- Noise Reduction: If the door will be used in a location that requires sound isolation—such as in hospitals, schools, or certain commercial buildings—choose a PUF door designed for significant acoustic insulation. The density and composition of the polyurethane foam can influence the door's ability to reduce noise.

- Security Requirements: Assess the security needs of the facility. PUF panel doors can be equipped with various security features, including reinforced panels and advanced locking mechanisms, suitable for sensitive areas in commercial and residential environments.

- Fire Resistance: Depending on the building's requirements, you might need PUF panel doors that offer enhanced fire resistance. Check the fire rating of the door, which indicates how long it can withstand fire exposure.

- Aesthetic Preferences: For settings where aesthetics are a priority, such as in modular homes or upscale commercial spaces, consider PUF panel flat doors that offer a sleek, modern look with customizable finishes that can blend with or enhance the building’s design.

Sourcing from Reputable PUF Panel Doors Manufacturer

Choosing the right PUF door manufacturer is as crucial as the door itself. Manufacturers like Technopuff Solutions, known for their commitment to quality and innovation, ensure that the PUF panel doors they produce meet the highest standards. When sourcing your door, consider:

- Reputation: Look for manufacturers with positive reviews and testimonials from previous customers.

- Experience: Companies with extensive experience in manufacturing PUF doors are more likely to provide high-quality products that deliver on performance promises.

- Customer Service: Make sure that the manufacturer provides excellent pre-sales and after-sales service. This support is crucial for addressing any concerns that may arise during or after installation.

By carefully considering these factors, assessing the quality and performance metrics, and choosing a reputable manufacturer like Technopuff Solutions, you can ensure that the PUF panel door you select will meet your needs effectively, offering optimal performance across its lifespan.

FAQs

A. PUF panel doors are advanced doors constructed with a core of polyurethane foam, offering excellent thermal and acoustic insulation. They are typically used in residential, commercial, and industrial settings.

A. By providing superior insulation, PUF panel doors help to maintain interior temperature, reducing the need for heating and cooling, which in turn lowers energy costs.

A. Yes, PUF doors manufacturers like Technopuff Solutions offer customizable options including sizes, finishes, and hardware to fulfil specific design requirements and functional needs.

A. PUF panel flat doors provide a sleek, modern look while offering the benefits of noise reduction and thermal efficiency, enhancing the comfort and usability of commercial spaces.

A. Absolutely, PUF panel doors are known for their durability and strength, capable of withstanding environmental stress while maintaining their integrity and appearance.

A. Yes, the insulation material in PUF panel doors not only manages thermal insulation but also significantly reduces noise, making them suitable for environments where sound reduction is critical.

A. Technopuff Solutions is known for its high-quality manufacturing standards, wide range of customization options, and excellent customer service, making them a preferred provider of PUF panel doors.

A. Yes, PUF panel doors are excellent for exterior use due to their insulative properties and strength, making them ideal for withstanding harsh climates and environmental conditions.

Conclusion

Throughout this discussion, we have extensively covered the numerous benefits and applications of PUF panel doors. These doors, renowned for their superior thermal and acoustic insulation, energy efficiency, durability, and fire resistance, represent a significant advancement in door technology, suitable for a wide range of environments—from industrial and commercial to residential settings.

PUF panel doors are particularly noted for their ability to maintain comfortable interior climates, reduce energy costs, and enhance the overall security and safety of buildings. Whether you are constructing a new modular home, upgrading an office building, or setting up specialized facilities like clean rooms or data centers, these doors offer tailored solutions that meet stringent performance and aesthetic requirements.

We strongly encourage all architects, builders, and homeowners to consider PUF panel doors for their next projects. The customization options available, including various sizes, finishes, and hardware choices, make them an excellent choice for any construction endeavor that values quality, efficiency, and durability.

As a leading PUF doors manufacturer, Technopuff Solutions offers a wealth of experience and a commitment to excellence that can help guide you through the selection process. Consulting with Technopuff Solutions can provide you with access to tailored solutions, allowing you to view product samples and schedule detailed consultations to ensure that your specific needs are met.

In conclusion, PUF panel doors represent a smart investment for any construction or renovation project. By choosing these innovative doors, you are opting for a product that will provide lasting benefits, enhancing the functionality and aesthetics of your space. We encourage you to reach out to Technopuff Solutions to discover how these exceptional doors can be integrated into your upcoming projects, ensuring optimal results that stand the test of time.

To get detailed information about PUF Panels, go to our dedicated PUF Panels page.