PPGI vs PPGL Sheet: Which is best for PUF Panel

In recent years, prefabricated construction has transformed the way we think about building fast, durable, and cost-effective structures. At the heart of this transformation lies the PUF Panel, a high-performance sandwich panel that provides superior insulation, strength, and ease of installation. Whether it’s for industrial buildings, clean rooms, or modern site offices, PUF Panels have proven to be a game changer — especially in the creation of stylish and functional PUF Panel guest houses.

Among various prefab building applications, the PUF Panel stands out as a trending solution for eco-friendly, modular living. These structures are not only quick to assemble but also offer excellent thermal comfort and aesthetic appeal. And a major factor that determines the performance and durability of these panels is the type of metal facing sheet used — typically a PPGI sheet or a PPGL sheet.

At Technopuff Solutions, a leading manufacturer of PUF Panels in India, we offer our clients the flexibility to choose between both PPGI PUF panel and PPGL PUF panel configurations. Each option comes with its own unique advantages, depending on the intended environment and usage.

So, what’s the difference? And more importantly — which sheet is better for your PUF Panel: a PPGI sheet or a PPGL sheet? In this article, we’ll dive deep into the technical details, real-world applications, and cost-benefit analysis of PPGI vs PPGL to help you make an informed decision.

What Are PPGI and PPGL Sheets?

When it comes to the outer facings of high-quality PUF panels, the choice of metal sheets significantly impacts performance, longevity, and appearance. Two of the most commonly used materials are PPGI and PPGL, both of which are types of pre-coated steel known for their strength, durability, and corrosion resistance. Let’s explore what these materials are and why they matter in PUF Panel construction.

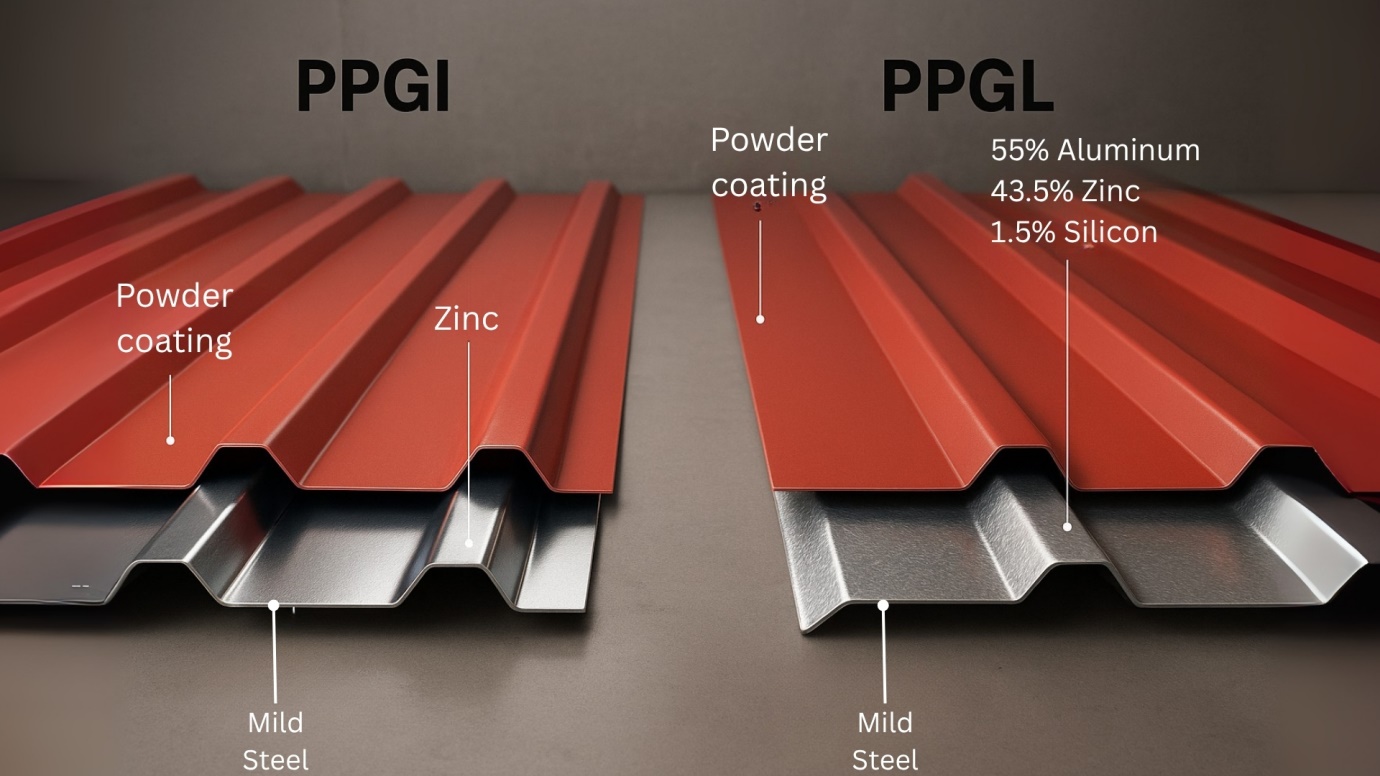

What is PPGI?

PPGI stands for Pre Painted Galvanized Iron. It is made by coating cold rolled steel with a layer of zinc (galvanization) and then applying a durable paint coating on top. The result is a corrosion-resistant, weatherproof material with excellent aesthetic appeal.

A typical PPGI steel sheet comprises:

- A base layer of cold rolled steel

- A hot-dipped zinc coating (galvanized)

- Multiple layers of primer and top coat paint

These pre painted galvanized iron sheets are widely used in roofing, wall cladding, and especially as the protective skin in PUF panels, where they serve as the outer facing layer.

What is PPGL?

PPGL stands for Pre Painted Galvalume. It is similar in structure to PPGI, but instead of just zinc, the metallic coating is made of a 55% aluminum, 43.5% zinc, and 1.5% silicon alloy — known as Galvalume. This special composition offers even better resistance to corrosion, heat, and environmental wear, especially in coastal and industrial regions.

A standard PPGL steel sheet includes:

- A base layer of cold rolled steel

- A galvalume coating

- Primer and topcoat paint similar to PPGI

The pre painted galvalume sheet is highly valued for its reflectivity, thermal resistance, and longer lifespan, making it ideal for external applications where weathering is a major concern.

Why These Sheets Matter in PUF Panels

In a PUF Panel, these metal sheets act as the outer skins enclosing a rigid polyurethane foam core. Their role is critical — they provide structural support, impact resistance, weather protection, and aesthetic finish.

Whether you choose PPGI steel or PPGL steel, both deliver strength and performance — but their selection should depend on your environment, budget, and desired longevity.

Technical Comparison: PPGI vs PPGL Sheet

Choosing the right outer material for your PUF panels plays a crucial role in the longevity, cost, and performance of your building. When it comes to PPGI vs PPGL sheet, both options offer excellent qualities, but each serves specific environmental and structural needs.

At Technopuff Solutions, we help you make that choice easier by offering custom-built PUF panels using both PPGI and PPGL materials — whether you’re looking for a sleek PPGI colour coated sheet or a corrosion-resistant PPGL colour coated sheet.

Let’s break down the PPGL vs PPGI comparison based on key technical aspects:

PPGI vs PPGL Sheet – Side-by-Side Technical Comparison

Feature | PPGI | PPGL |

Base Metal | Cold Rolled Steel | Cold Rolled Steel |

Metallic Coating | Zinc (Galvanized) – Used in PPGI coated coil | 55% Aluminum + 43.5% Zinc + 1.5% Silicon (Galvalume) – used in PPGL sheet |

Corrosion Resistance | Good for inland and low-moisture areas | Superior corrosion resistance, especially in coastal or industrial zones |

Heat Resistance | Withstands up to ~200°C | Withstands up to ~315°C – Ideal for hot climates and sunny regions |

Aesthetic Appearance | Smooth, matte or glossy finish – Available as PPGI colour coated sheet | Shiny spangled finish, also available in multiple colors as PPGL colour coated sheet |

Formability | Excellent – Suitable for rolling, bending (PPGI sheet) | Good, slightly less flexible than PPGI due to aluminum content |

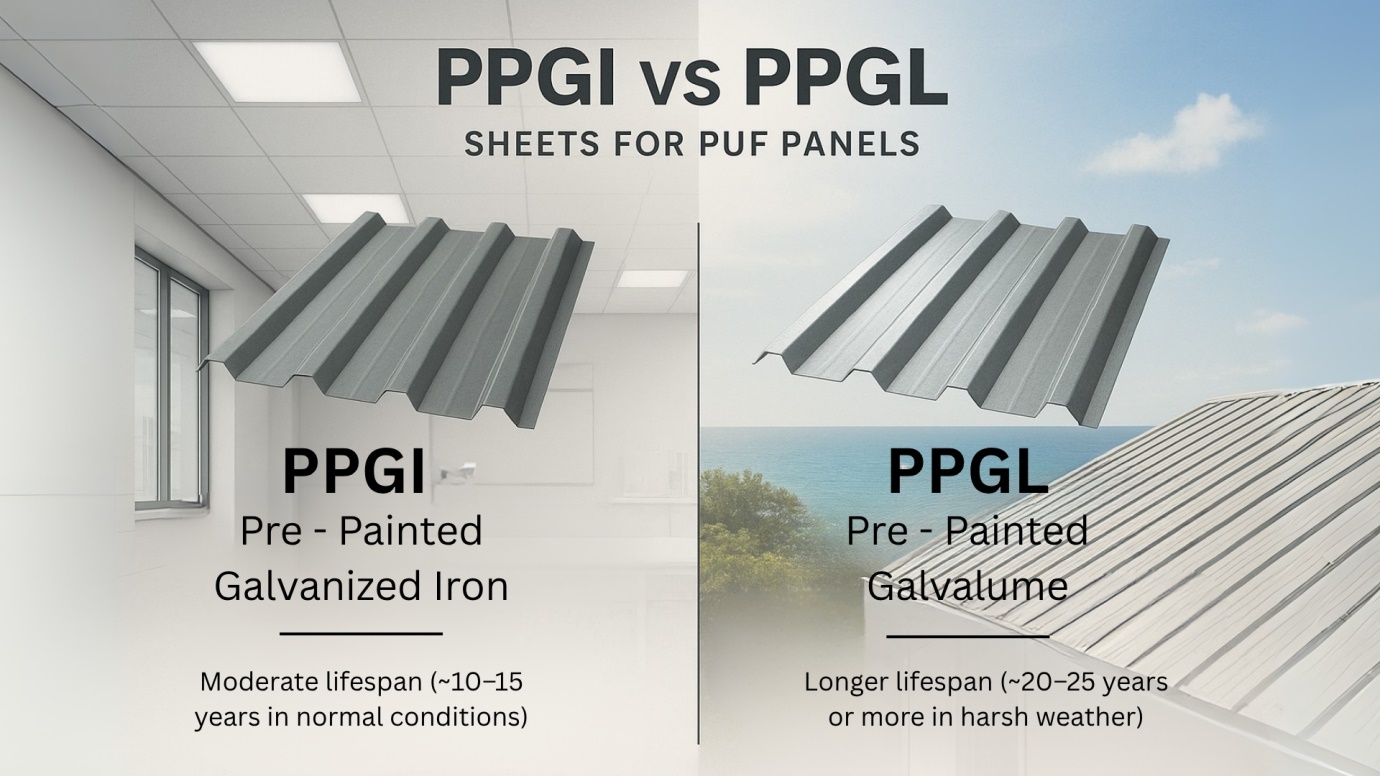

Durability | Moderate lifespan (~10–15 years in normal conditions) | Longer lifespan (~20–25 years or more in harsh weather) |

Cost | More cost-effective upfront – Best for budget-sensitive projects | Higher initial cost, but greater ROI due to reduced maintenance and longer life |

The debate between PPGI vs PPGL sheet isn’t about which is better universally — it’s about what fits your project’s needs. If you’re building a cost-conscious guest house in a moderate climate, a PPGI panel may be perfect. But if you want a long-lasting solution with superior environmental resistance, the PPGL colour coated sheet is your go-to option.

Environmental Suitability: Where Each One Shines

When selecting the outer skin for your PUF panel, understanding the environmental suitability of the material is just as important as knowing its technical specifications. Climate, humidity, location, and exposure levels all impact the long-term performance of your structure. That’s why choosing between a PPGI or PPGL panel must be based on where and how the panel will be used.

Let’s explore the best environmental applications for each material — and where each one truly shines.

PPGI – Perfect for Dry, Moderate Environments

A PPGI sheet is an excellent option for inland areas, low-humidity climates, and interior applications. These regions experience minimal exposure to salt-laden air, acid rain, or extreme moisture — conditions in which PPGI sheet performs reliably over the years.

Best suited for:

Because PPGI is lightweight, easy to install, and available in various profiles, it is a popular choice for cost-effective prefab construction using prepainted galvanized steel coil.

PPGL – Built to Withstand Harsh Weather and Humidity

For coastal regions, industrial zones, and areas with high rainfall or humidity, a PPGL roofing sheet offers significantly better durability and corrosion resistance. Thanks to its aluminum-zinc coating, a PPGL steel coil forms a stable barrier against oxidation, chemical fumes, and saltwater exposure.

Best suited for:

A PPGL roofing sheet not only resists corrosion but also maintains its color and structural integrity for 20+ years, making it the ideal choice for long-term outdoor applications.

To get the best performance from your PUF panel, always match your facing sheet to the environment in which it will operate. A PPGI steel coil is budget-friendly and reliable for mild conditions, while a PPGL steel coil is the go-to solution for moisture-prone or chemically exposed regions.

Cost vs Long-Term Value: Making the Right Investment

When choosing between PPGI vs PPGL, many customers focus solely on upfront pricing — but that’s only part of the story. To make a smart, future-proof investment for your prefab structure or PUF Panel guest house, it’s crucial to weigh initial costs against long-term returns.

Let’s dive into how PPGI and PPGL differ in terms of cost-effectiveness, durability, and maintenance — so you can decide which offers true value for your project.

PPGI: Budget-Friendly for Short-Term Savings

A major advantage of PPGI is its low initial cost. Whether you're buying for a small site cabin or a modular interior project, the PPGI sheet price is significantly more affordable compared to other cladding options.

Why PPGI is appealing for short-term use:

However, while the PPGI sheet price helps reduce upfront expenses, it’s important to note that maintenance costs can accumulate over time — especially in humid or corrosive environments. Over the years, weathering, repainting, and surface corrosion may require more frequent upkeep.

PPGL: Long-Term ROI Through Durability

In contrast, a PPGL sheet may come at a higher upfront cost, but it offers substantial long-term value. The PPGL sheet price reflects its superior resistance to corrosion, heat, and moisture, making it a reliable solution for coastal, industrial, or exterior-facing applications.

Why PPGL pays off over time:

Though the PPGL sheet rate may appear higher at first glance, the total lifecycle cost is lower — especially when you factor in savings on repairs, replacements, and labor.

PPGI vs PPGL: Value Comparison Table

Feature | PPGI | PPGL |

Initial Cost | Lower (PPGI sheet price friendly) | Higher (PPGL sheet price is premium) |

Maintenance Needs | Moderate to High | Very Low |

Weathering Resistance | Average | Excellent |

Repainting Frequency | Every 5–7 years | 10–15+ years, often not needed |

Total Lifecycle Cost | Medium to High | Low (Great ROI) |

If your priority is cost control for a short-term build, going with a PPGI sheet can be a smart decision. However, if you’re planning a long-lasting structure — especially in areas with environmental stress — the PPGL sheet rate is justified by the long-term savings and durability it offers.

Our Offering at Technopuff Solutions

At Technopuff Solutions, we take pride in being one of the most trusted PUF panel manufacturers in India, known for delivering high-performance, energy-efficient, and durable solutions tailored to diverse construction needs. Whether you’re building a modern prefab guest house, a cold storage facility, or an industrial site office, we provide premium-grade PUF panels backed by technology, precision, and care.

What sets us apart is our flexibility and customization. We offer both PPGI PUF panel and PPGL PUF panel configurations — allowing you to choose the most suitable solution based on your climate, location, and budget.

PPGI PUF Panel – Budget-Friendly & Reliable

Our PPGI PUF panel range features top-quality insulation cores enclosed within robust PPGI sheet facings. These panels are ideal for:

With PPGI panel options available in various thicknesses and finishes, we ensure strength without compromising on cost-efficiency.

PPGL PUF Panel – Premium Protection for Harsh Environments

For clients looking for long-term performance and superior corrosion resistance, our PPGL PUF panel is the preferred choice. Manufactured using high-grade PPGL sheet, these panels offer:

Whether it’s for coastal resorts, industrial zones, or rooftop structures, our PPGL sheet-based panels are engineered to endure and perform.

Why Choose Us?

- Custom Manufacturing: Every project is unique — we adapt panel thickness, facings, and core material to match your specific requirements.

- Uncompromised Quality: Our panels undergo rigorous quality checks to meet both national and international standards.

- Dedicated After-Sales Support: From consultation to installation and beyond, our expert team is here to ensure your satisfaction at every stage.

- Timely Delivery Across India: As established PUF panel manufacturers in India, we cater to residential, commercial, and industrial clients nationwide.

At Technopuff Solutions, we’re not just supplying panels — we’re building trust, comfort, and durability into every project. Whether you choose a PPGI PUF panel or a PPGL PUF panel, you can be confident that you’re investing in quality that lasts.

FAQs

A. A PPGI sheet is made from pre-painted galvanized iron, while a PPGL sheet consists of pre-painted galvalume. The key difference lies in the coating — PPGI uses zinc, whereas PPGL uses a combination of aluminum, zinc, and silicon, making it more corrosion-resistant.

A. Yes, the PPGI sheet price is generally lower than the PPGL sheet price, making it a cost-effective option for short-term or interior uses. However, PPGL offers better value for long-term outdoor projects.

A. The PPGL PUF panel is highly durable and performs exceptionally well in industrial areas exposed to chemical fumes and moisture. The PPGL sheet ensures longevity and minimal maintenance.

A. Both PPGI and PPGL are made from cold rolled steel coils. In PPGI, the steel is coated with zinc, while in PPGL, the steel is coated with galvalume, a mix of aluminum, zinc, and silicon.

A. PPGI steel coil performs well in dry, moderate conditions, while PPGL steel coil is designed for humid, coastal, or chemically aggressive environments where corrosion is a concern.

A. A PPGL profile sheet is commonly used for roofing, wall cladding, and external paneling in areas requiring high corrosion resistance, such as industrial and coastal locations.

A. Yes, PPGI corrugated sheets provide reliable structural strength for roofing and cladding applications in non-corrosive environments and are frequently used in prefab constructions.

A. While PPGI is more affordable upfront, PPGL is more cost-effective over time due to lower maintenance and longer lifespan, especially in harsh climates.

A. A PPGI PUF panel may last around 10–15 years under moderate conditions, while a PPGL PUF panel can exceed 20–25 years with minimal upkeep in challenging environments.

A. Yes, Technopuff Solutions is among the leading PUF panel manufacturers in India, offering high-quality, customizable panels with expert support and reliable after-sales service.

Conclusion

Choosing between a PPGI sheet and a PPGL sheet comes down to your specific project needs — whether you’re looking for short-term affordability or long-term performance. Throughout this guide, we’ve explored the key differences between the two, helping you understand the advantages of each when used in a PUF panel.

- A PPGI PUF panel is best suited for inland areas, dry climates, and interior walls, offering an economical solution without compromising on strength.

- A PPGL PUF panel, on the other hand, is ideal for coastal, industrial, or high-humidity environments, providing unmatched durability and resistance against corrosion, UV, and weathering.

When comparing PPGI vs PPGL, it’s essential to consider not just the initial cost but the total value over the panel’s lifespan. While the PPGI sheet is budget-friendly upfront, the PPGL sheet offers greater ROI for long-term outdoor use.

At Technopuff Solutions, we’re committed to helping you make the most informed choice possible. As leading PUF panel manufacturers in India, we combine superior materials, advanced manufacturing, and personalized support to deliver both PPGI PUF panel and PPGL PUF panel solutions tailored to your unique needs.

Need Expert Advice? Let’s Talk.

Still unsure which panel type suits your project? Our team is here to assist you every step of the way — from technical consultation to final delivery.

- Request a custom quote

- Get design and material guidance

- Explore our latest PUF panel solutions

Contact us today for a no-obligation consultation and discover why we’re the trusted name for PUF panels across India.

To know more about our range of PUF panels, products, and services, feel free to visit our Homepage.